Extra-high-pressure-resistant high-temperature-resistant mixed silicone rubber and preparation method thereof

A technology of mixing silicone rubber, high pressure and high temperature, applied in the field of silicone rubber, can solve the problems of unusable, silicone rubber breakdown voltage strength, volume resistivity and other electrical properties improvement, to ensure stability, improve volume resistivity, The effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

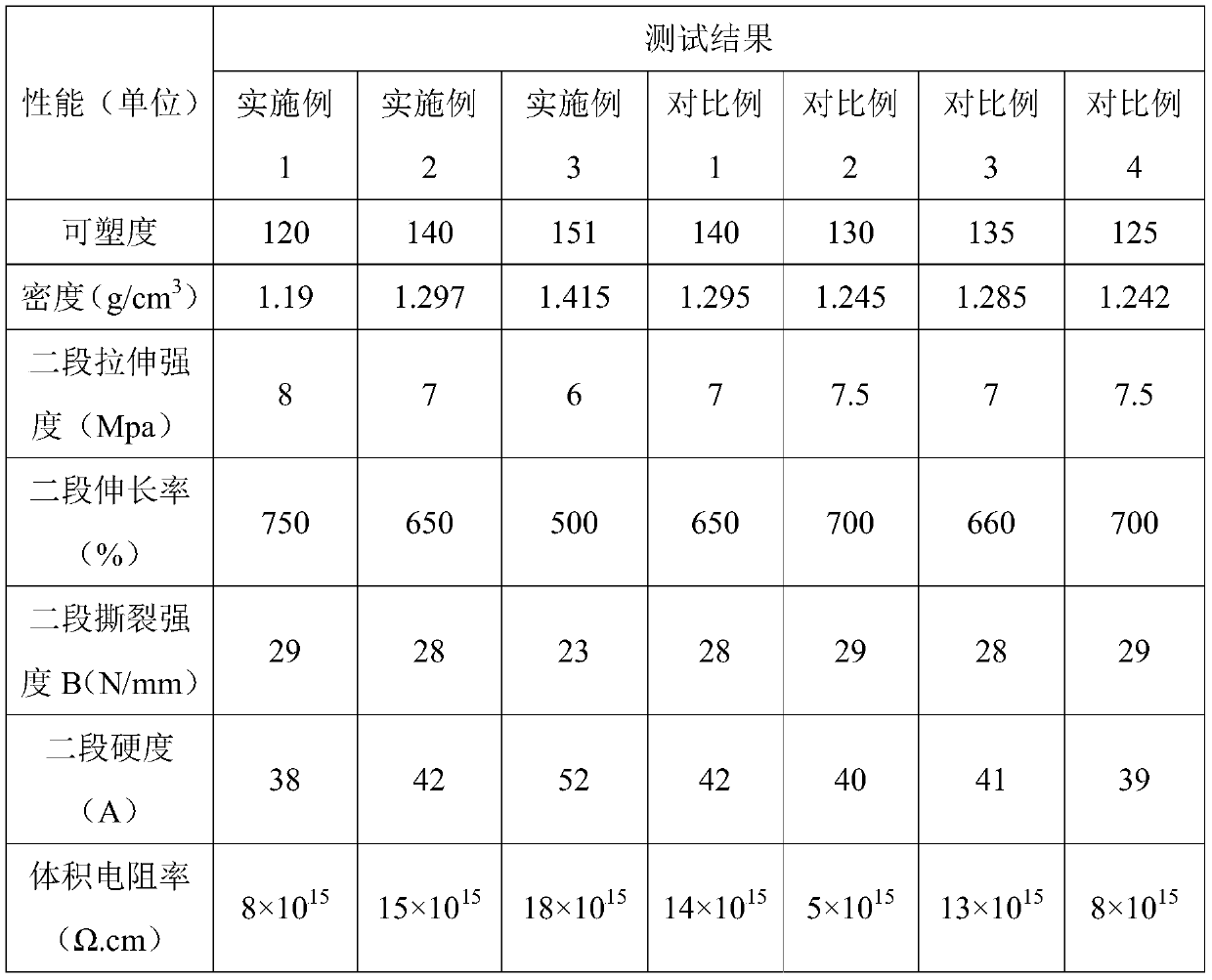

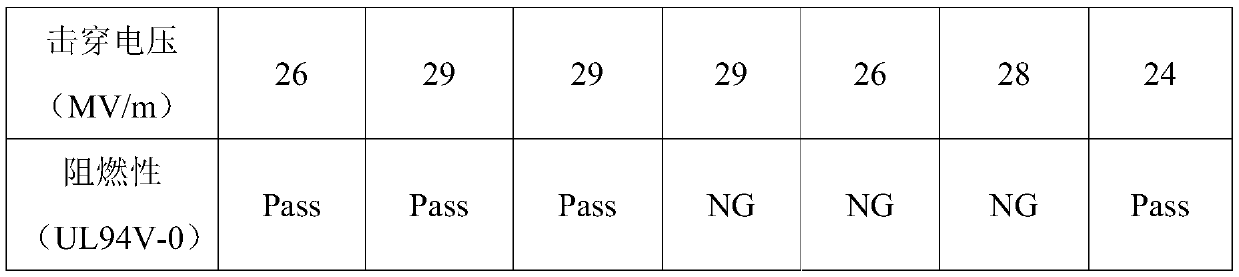

Examples

Embodiment 1

[0028] Embodiment 1 A kind of ultra-high pressure and high temperature resistant mixing silicone rubber

[0029] The described ultra-high pressure and high temperature resistant mixed silicone rubber consists of the following components and parts by weight:

[0030] 70 parts of methyl vinyl silicone rubber raw rubber, 20 parts of fumed silica, 3 parts of hexamethyldisilazane, 1 part of dimethyldiethoxysilane, 0.1 part of zinc stearate, 5 parts of silicon micropowder 5 parts of nitrogen compound, 5 parts of iron oxide, 1 part of titanium dioxide, 0.1 part of vinyltriethoxysilane, 0.5 part of distilled water, 1 part of cerium oxide, and 1 part of flame retardant.

[0031] The methyl vinyl silicone rubber raw rubber is a methyl vinyl silicone rubber raw rubber with a vinyl-terminated vinyl molar content of 0.03% and a methyl vinyl silicone rubber raw rubber with a vinyl-terminated vinyl molar content of 0.05%. Composition by weight ratio 5:4.

[0032] The nitrogen compound is a...

Embodiment 2

[0038] Embodiment 2 A kind of ultra-high pressure and high temperature resistant mixing silicone rubber

[0039] The high-pressure and high-temperature resistant mixing silicone rubber consists of the following components and parts by weight: 100 parts of methyl vinyl silicone rubber raw rubber, 25 parts of fumed white carbon black, 5 parts of hexamethyldisilazane Parts, 2 parts of dimethyldiethoxysilane, 0.6 parts of zinc stearate, 18 parts of silicon micropowder, 12 parts of nitrogen compounds, 13 parts of iron oxide, 3 parts of titanium dioxide, 0.8 parts of vinyltriethoxysilane, distilled water 2 parts, 2 parts of cerium oxide, 2 parts of flame retardant.

[0040] The methyl vinyl silicone rubber raw rubber is vinyl terminated methyl vinyl silicone rubber with a vinyl molar content of 0.08% and vinyl terminated methyl vinyl silicone rubber with a vinyl molar content of 0.16%. Composition by weight ratio 7:3.

[0041] The nitrogen compound is silicon nitride.

[0042] Th...

Embodiment 3

[0047] Embodiment 3 A kind of ultra-high pressure and high temperature resistant mixing silicone rubber

[0048] The described ultra-high pressure and high temperature resistant mixed silicone rubber consists of the following components and parts by weight:

[0049] 120 parts of raw methyl vinyl silicone rubber, 30 parts of fumed silica, 6 parts of hexamethyldisilazane, 3 parts of dimethyldiethoxysilane, 1 part of zinc stearate, 30 parts of silicon micropowder 20 parts of nitrogen compound, 20 parts of iron oxide, 5 parts of titanium dioxide, 1 part of vinyltriethoxysilane, 3 parts of distilled water, 5 parts of cerium oxide, and 3 parts of flame retardant.

[0050] The methyl vinyl silicone rubber raw rubber is a methyl vinyl silicone rubber raw rubber with a vinyl-terminated vinyl molar content of 0.09% and a methyl vinyl silicone rubber raw rubber with a vinyl-terminated vinyl molar content of 0.30%. Composition by weight ratio 8:2.

[0051] The nitrogen compound is compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com