A solvent-free addition type liquid silicone resin

An addition type, liquid silicon technology, applied in the field of solvent-free addition type liquid silicone resin and its preparation, can solve the problems of long time, high energy consumption, unstable storage, etc., and achieve good electrical insulation properties and good weather resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

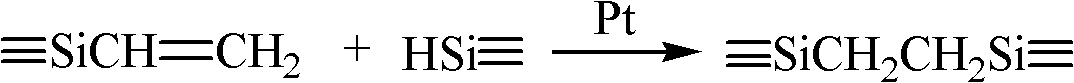

Method used

Image

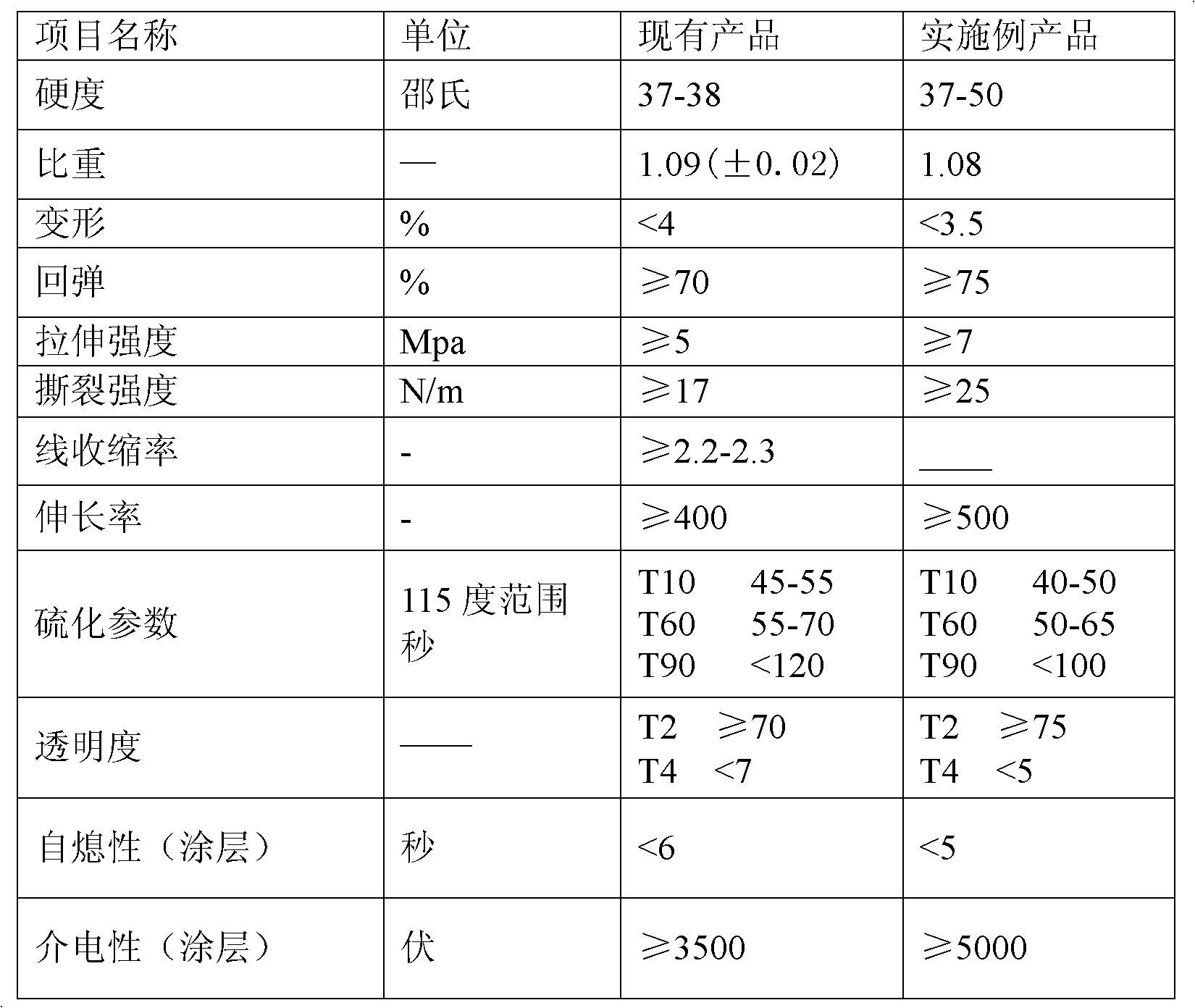

Examples

Embodiment 1

[0024] Embodiment 1, the preparation of vinyl silicone oil for liquid silicone resin

[0025] Use D4 (octamethyltetrasiloxane) or DMC monomer to undergo dehydration polymerization in a reactor, raise the temperature to 180°C, add vinyl double-caps, and then remove low-molecular substances, and the weight ratio of ethylene content in the output is 0.3%. , Vinyl silicone oil with a viscosity of 10000-50000cs.

Embodiment 2

[0026] Embodiment 2, preparation of a solvent-free addition type liquid silicone resin

[0027] In parts by weight, prepare the following raw materials: 100 parts of vinyl silicone oil with an ethylene content of 0.3% by weight and a viscosity of 10000-50000cs; 38 parts of fumed silica (particle size 10-20nm, specific surface area 160-300m 2 / g); treatment agent comprises 5 parts of hexamethylsilazane, 0.5 part of vinyltriethoxysilane, 0.5 part of dimethyldiethoxysilane; and 2 parts of water; 0.06 part of release agent stearic acid ; Inhibitor methyl butynol 0.001 parts, crosslinking agent hydrogen-containing silicone oil 0.6 parts; prepared by addition method. The preparation method comprises the following steps:

[0028]1. Put half of the total weight of vinyl silicone oil (product of Example 1) and silicon dioxide into the kneader, then add hexamethyldisilazane, vinyltriethoxysilane, dimethyldiethoxysilane , water, stearic acid, and kneaded for 2 hours to obtain a rubber ...

Embodiment 3

[0031] Embodiment 3, preparation of a solvent-free addition type liquid silicone resin

[0032] In parts by weight, prepare the following raw materials: 130 parts of vinyl silicone oil with an ethylene content of 0.3% by weight and a viscosity of 10000-50000cs; 58 parts of fumed silicon dioxide (particle size 10-20nm, specific surface area 160-300m 2 / g); treatment agent includes 10 parts of hexamethylsilazane, 2 parts of vinyltriethoxysilane, 2 parts of dimethyldiethoxysilane; and 5 parts of water; 0.09 part of release agent stearic acid ; 0.003 parts of methyl butynol inhibitor, 0.8 parts of hydrogen-containing silicone oil as a crosslinking agent; 2 parts of aluminum hydroxide as a high-temperature resistance additive, prepared by an addition method. The preparation method comprises the following steps:

[0033] 1. Put half of the total weight of vinyl silicone oil and silicon dioxide into the kneader, then add hexamethyldisilazane, vinyltriethoxysilane, dimethyldiethoxysi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com