Production process of tetramethyldivinyldisiloxane

A technology of tetramethyldivinyldisiloxane and tetramethyldivinyldisiloxane, which is applied in the direction of silicon organic compounds, can solve the problems of wasting investment costs and difficult disposal, and reduce environmental protection The effect of pressure, sodium ethoxide content reduction, and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

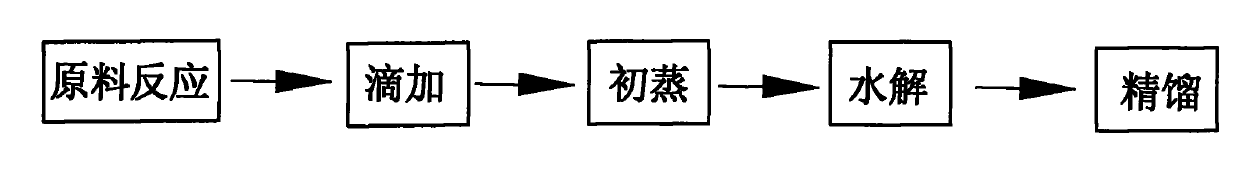

[0025] The production process of tetramethyldivinyldisiloxane, such as figure 1 shown, including the following steps:

[0026] The first step: put dimethyldiethoxysilane and metal sodium into the reaction kettle, heat the reaction kettle, raise the temperature to dissolve dimethyldiethoxysilane and metal sodium, and pass chlorine after the dissolution is complete For ethylene, control the temperature at 90°C and control the pressure at 0MPa to make it react;

[0027] Step 2: Take dimethyldichlorosilane and store it in a storage tank for later use, then put the above reaction product into the initial steamer, then open the valve of the storage tank, and start to add dimethyl dichlorosilane dropwise to the initial steamer. Dichlorosilane, the speed is controlled at 8-18L / h, and the temperature of the initial steamer is controlled at 70°C at the same time, and the pressure of the initial steamer is controlled at 0MPa. Small amount of addition or even close the valve, until the ...

Embodiment 2

[0039] The production technology of tetramethyl divinyl disiloxane comprises the steps:

[0040] The first step: put dimethyldiethoxysilane and metal sodium into the reaction kettle, heat the reaction kettle, raise the temperature to dissolve dimethyldiethoxysilane and metal sodium, and pass chlorine after the dissolution is complete For ethylene, control the temperature at 70°C and control the pressure at 0.2MPa to make it react;

[0041] Step 2: Take dimethyldichlorosilane and store it in a storage tank for later use, then put the above reaction product into the initial steamer, then open the valve of the storage tank, and start to add dimethyl dichlorosilane dropwise to the initial steamer. Dichlorosilane, the speed is controlled at 8-17L / h. At the same time, the temperature of the initial steamer is controlled at 60°C by using the jacket heating or cooling system, and the pressure of the initial steamer is controlled at 0.1MPa. During this process, when the kettle pressure o...

Embodiment 3

[0047] The production technique of tetramethyl divinyl disiloxane is characterized in that: comprises the steps:

[0048] The first step: put dimethyldiethoxysilane and metal sodium into the reaction kettle, heat the reaction kettle, raise the temperature to dissolve dimethyldiethoxysilane and metal sodium, and pass chlorine after the dissolution is complete For ethylene, control the temperature at 70°C and control the pressure at 0MPa to make it react;

[0049] Step 2: Take dimethyldichlorosilane and store it in a storage tank for later use, then put the above reaction product into the initial steamer, then open the valve of the storage tank, and start to add dimethyl dichlorosilane dropwise to the initial steamer. Dichlorosilane, the speed is controlled at 8-18L / h, while the temperature of the initial steamer is controlled at 60°C, and the pressure of the initial steamer is controlled at 0MPa. During this process, when the pressure of the still or the temperature of the stil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com