Electrical insulating packaging material and preparation method thereof

A packaging material and electrical insulation technology, which is applied in the field of electrical insulation packaging materials and its preparation, can solve problems such as undiscovered performance, and achieve the effects of improving curing performance, good electrical insulation performance, and good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

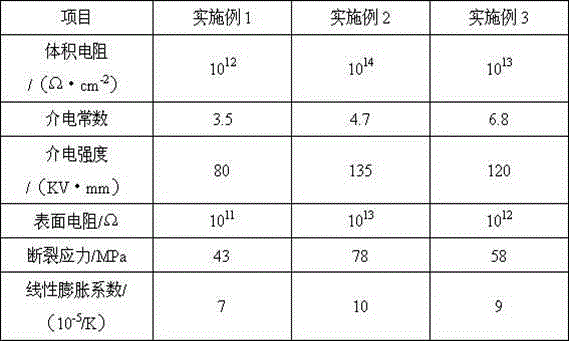

Examples

Embodiment 1

[0027] An electrical insulating packaging material, the packaging material is mainly made of carrier material, adhesive resin, silicone resin; the carrier material is made according to the following ratio of raw materials by weight: 25 parts of epoxy resin, phenolic resin 15 parts, 12 parts of polyvinyl chloride, 8 parts of weather-resistant acrylic resin; The adhesive resin is melamine formaldehyde resin or melamine urea formaldehyde resin suitable for impregnation, wherein the resin solid content is 35%; The silicone resin is as follows Raw materials are prepared by proportioning parts by weight: 15 parts of methyltriethoxysilane, 12 parts of dimethyldiethoxysilane, 8 parts of silicon carbide, and 25 parts of organic solvent.

[0028] A method for preparing an electrical insulating packaging material, comprising the following steps:

[0029] (1) Melt epoxy resin, phenolic resin, polyvinyl chloride and weather-resistant acrylic resin at high temperature, and mix them evenly. ...

Embodiment 2

[0036] An electrical insulating packaging material, the packaging material is mainly made of carrier material, adhesive resin, silicone resin; the carrier material is made according to the following ratio of raw materials by weight: 40 parts of epoxy resin, phenolic resin 28 parts, 25 parts of polyvinyl chloride, 20 parts of weather-resistant acrylic resin; The adhesive resin is melamine formaldehyde resin or melamine urea formaldehyde resin suitable for impregnation, wherein the resin solid content is 50%; The silicone resin is as follows Raw materials are prepared by proportioning parts by weight: 35 parts of methyltriethoxysilane, 25 parts of dimethyldiethoxysilane, 20 parts of silicon carbide, and 50 parts of organic solvent.

[0037] A method for preparing an electrical insulating packaging material, comprising the following steps:

[0038] (1) Melt epoxy resin, phenolic resin, polyvinyl chloride and weather-resistant acrylic resin at high temperature and mix them evenly....

Embodiment 3

[0045] An electrical insulating packaging material, the packaging material is mainly made of carrier material, adhesive resin, silicone resin; the carrier material is made according to the following ratio of raw materials by weight: 50 parts of epoxy resin, phenolic resin 35 parts, 30 parts of polyvinyl chloride, 25 parts of weather-resistant acrylic resin; The adhesive resin is melamine formaldehyde resin or melamine urea formaldehyde resin suitable for impregnation, wherein the resin solid content is 55%; The silicone resin is as follows Raw materials are prepared by proportioning parts by weight: 40 parts of methyltriethoxysilane, 30 parts of dimethyldiethoxysilane, 25 parts of silicon carbide, and 55 parts of organic solvent.

[0046] A method for preparing an electrical insulating packaging material, comprising the following steps:

[0047] (1) Melt epoxy resin, phenolic resin, polyvinyl chloride and weather-resistant acrylic resin at high temperature, and mix them evenly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com