Ceramic fireproof and fire-resistant silicone rubber, method for preparing same, ceramic compound belt with ceramic fireproof and fire-resistant silicone rubber and method for preparing ceramic compound belt

A technology of silicone rubber and ceramicization, applied in chemical instruments and methods, rubber layered products, synthetic resin layered products, etc. broken and other problems, to achieve the effect of easy quality control, excellent breakdown resistance, and excellent electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

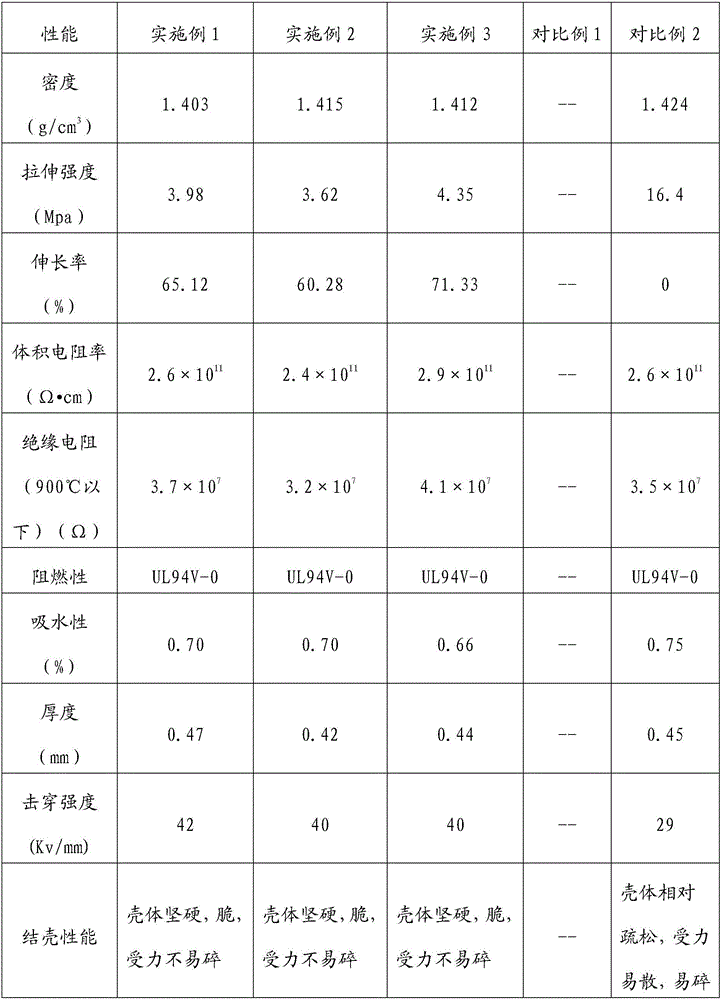

Examples

Embodiment 1

[0047] The ceramized fireproof and refractory silicone rubber of this embodiment is made of the following raw materials: 100kg of silicone rubber, 55kg of silicon dioxide, 7kg of dimethyldiethoxysilane, 50kg of vitrified powder, 1.5kg of stearic acid, Combustion agent 50kg, magnesium oxide 16kg, magnesium hydroxide 47kg and silane coupling agent 1.2kg. Among them, the flame retardant is silicon micropowder.

[0048] The preparation method of above-mentioned vitrified fireproof refractory silicone rubber comprises the following steps:

[0049] (1) Get 55kg of silicon dioxide, 7kg of dimethyldiethoxysilane and 1.2kg of silane coupling agent, after mixing uniformly, obtain the mixed material A;

[0050] (2) Take 100kg of silicone rubber and 1.5kg of stearic acid, put them into a kneader, open the cover and knead for 5 minutes until they are evenly mixed, then put them into the mixture A obtained in step (1) in 4 times, mix for 10 minutes, and obtain the mixture B ;

[0051] (3...

Embodiment 2

[0063] The ceramicized fireproof and refractory silicone rubber of this embodiment is made of the following raw materials: 100kg of silicone rubber, 54kg of silicon dioxide, 5kg of dimethyldiethoxysilane, 45kg of vitrified powder, 1.5kg of stearic acid, Combustion agent 50kg, magnesium oxide 10kg, magnesium hydroxide 47kg and silane coupling agent 1.7kg. Among them, the flame retardant is 25kg aluminum hydroxide and 25kg mica powder.

[0064] The preparation method of above-mentioned vitrified fireproof refractory silicone rubber comprises the following steps:

[0065] (1) Get 54kg silicon dioxide, 5kg dimethyldiethoxysilane and 1.7kg silane coupling agent, after mixing uniformly, obtain mixed material A;

[0066] (2) Take 100kg of silicone rubber and 1.5kg of stearic acid, put them into a kneader, open the cover and knead for 10 minutes until they are evenly mixed, then put them into the mixture A obtained in step (1) for 6 times, and mix for 15 minutes to obtain the mixture...

Embodiment 3

[0079] The ceramicized fireproof and refractory silicone rubber of this embodiment is made of the following raw materials: 100kg of silicone rubber, 55.5kg of silicon dioxide, 7kg of dimethyldiethoxysilane, 48kg of vitrified powder, 2kg of stearic acid, Combustion agent 60kg, magnesium oxide 10kg, magnesium hydroxide 32kg and silane coupling agent 0.7kg. Among them, the flame retardant is 20kg silica powder, 20kg aluminum hydroxide and 20kg mica powder.

[0080] The preparation method of above-mentioned vitrified fireproof refractory silicone rubber comprises the following steps:

[0081] (1) Get 55.5kg silicon dioxide, 7kg dimethyldiethoxysilane and 0.7kg silane coupling agent, after mixing uniformly, obtain mixed material A;

[0082] (2) Get 100kg of silicone rubber and 2kg of stearic acid, put them into a kneader, open the cover and knead for 5 minutes until they are evenly mixed, then put them into the mixture A obtained in step (1) in 4 times, mix for 10 minutes, and obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com