Low eutectic solvent for aromatic hydrocarbon separation and application thereof to extractive distillation

A technology of deep eutectic solvent and extractant, which is applied in the field of deep eutectic solvent and its application in extractive distillation, can solve the problems of complex ionic liquid synthesis method, high price, toxicity, etc., and achieve low toxicity and low price , prepare simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

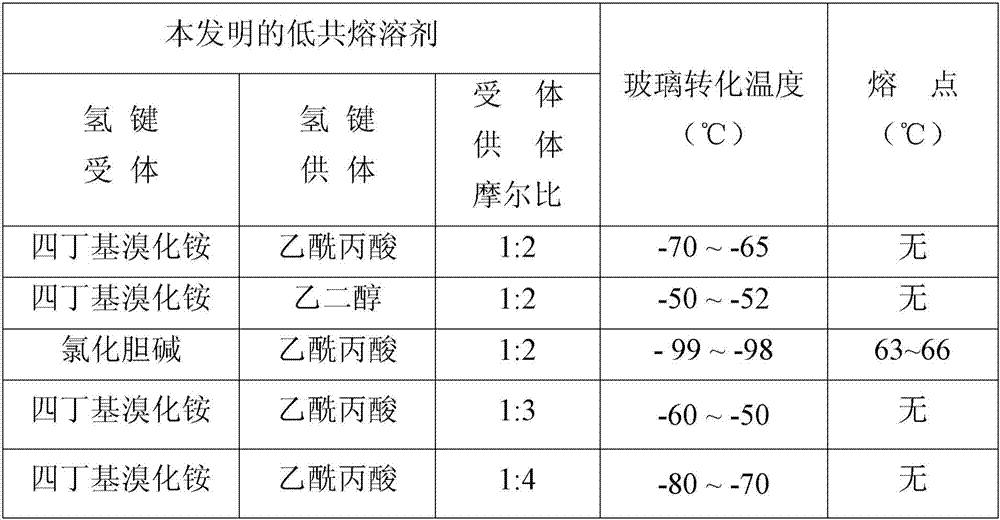

Method used

Image

Examples

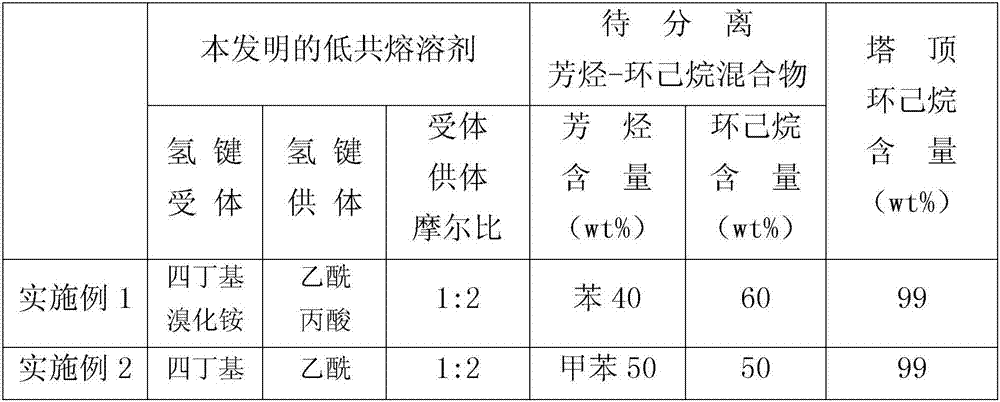

Embodiment 1

[0025] Weigh tetrabutylammonium bromide: levulinic acid = 1:2 (molar ratio), stir at 100°C until uniform and transparent to obtain the deep eutectic solvent of the present invention. A benzene-cyclohexane mixture is added to the kettle of the batch extracting and rectifying column, the content of benzene is 40wt%, and the cyclohexane is 60wt%. After heating to total reflux for 1 hour, preheat the deep eutectic solvent as an extractant, and then add it from the upper part of the tower. After continuing total reflux for 1 hour, adjust the reflux ratio. products and transition products. After testing, the content of cyclohexane and benzene products can reach 99%.

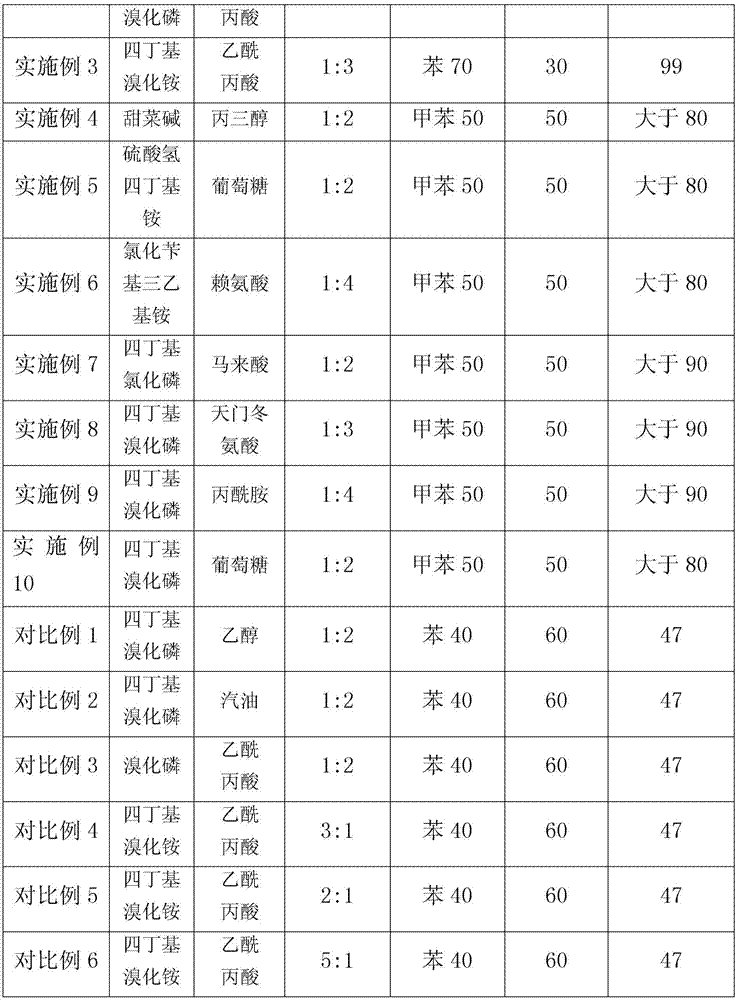

Embodiment 2-10

[0027] The experimental procedure is the same as in Example 1, except that there may be differences in hydrogen bond acceptors, hydrogen bond donors, the molar ratio of the two, aromatic hydrocarbons used in the test and their mass fractions. The experimental results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com