A kind of pt-ru-ir alloy spark plug electrode material and its preparation method and applied spark plug

A pt-ru-ir, electrode material technology, applied in the field of spark plugs, can solve the problems of increased resistivity, composition segregation, poor processing performance, etc., to achieve the effect of reducing resistivity, reducing dosage and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

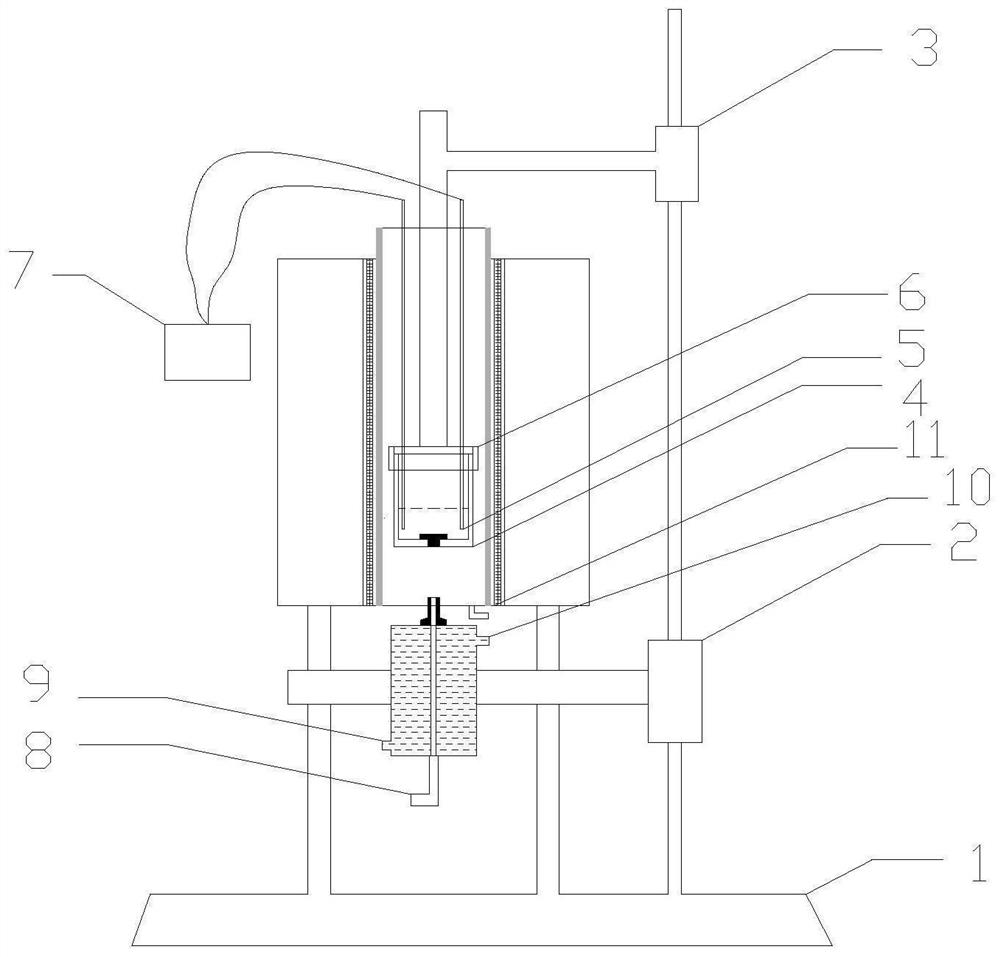

Method used

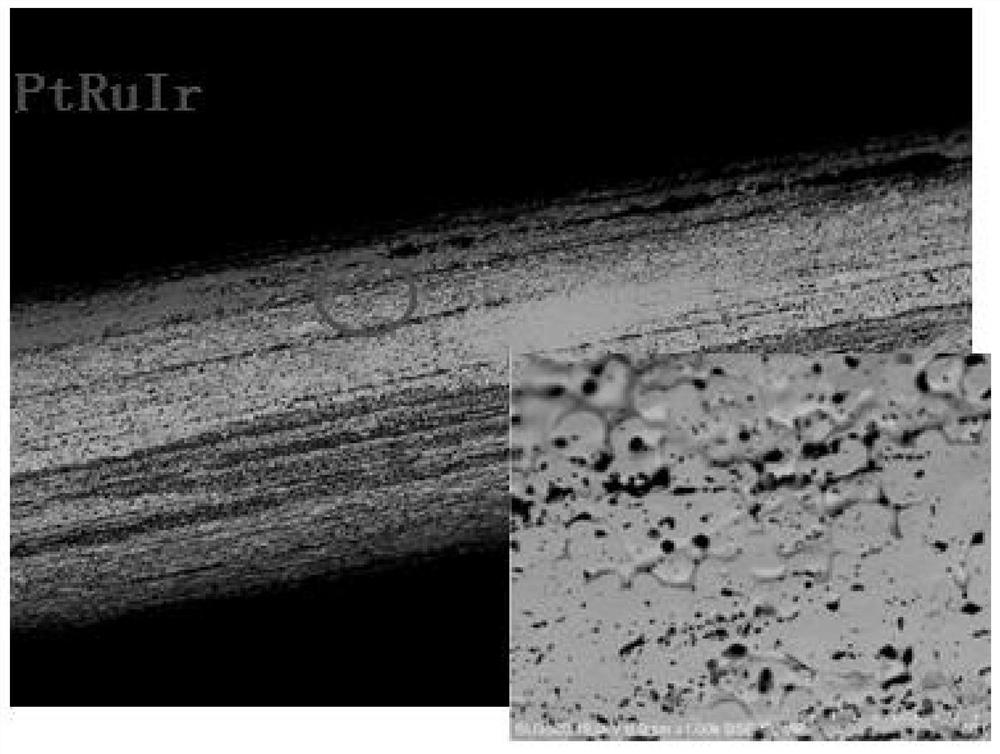

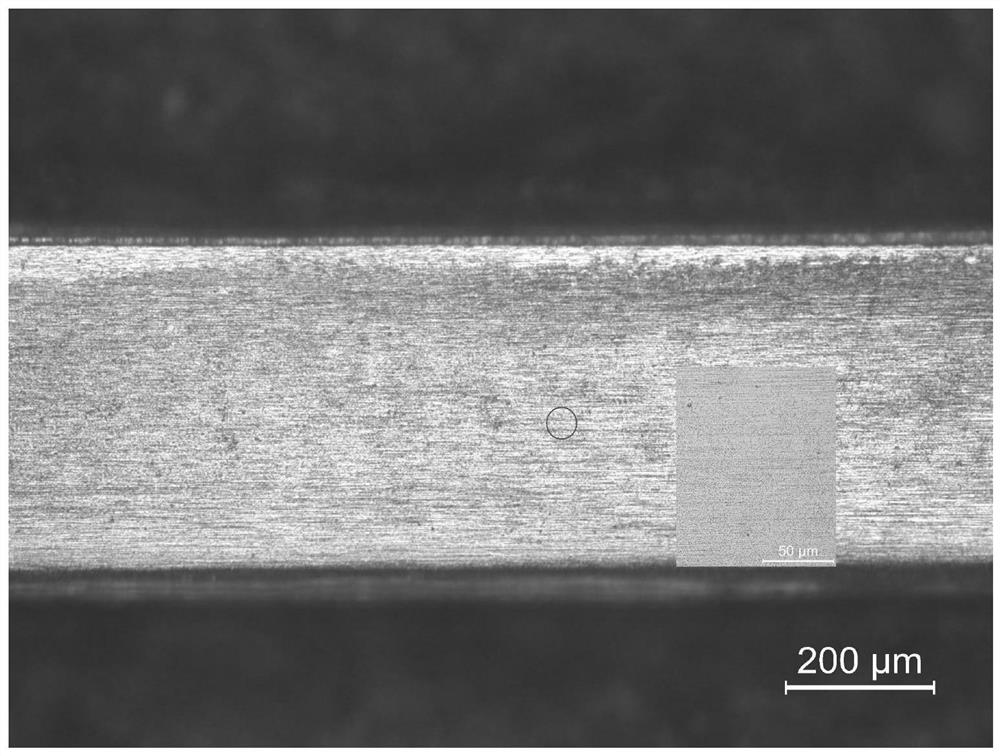

Image

Examples

Embodiment 1

[0040] A Pt-Ru-Ir alloy spark plug electrode material, the mass percentage ratio is 70% of Pt, 20% of Ru, and 10% of Ir. The preparation method is as follows: according to the nominal composition of the alloy, the corresponding elemental metal powder with a purity of 99.95% is weighed, mixed evenly, and placed in a crucible. Put the above-mentioned crucible into the induction furnace, pass in argon gas to form a protective atmosphere, raise the temperature of the furnace tube to 1950°C, and keep it warm for 5 minutes. After the metal powder raw material is completely melted, it is directly cast into alloy waste.

Embodiment 2

[0042] A Pt-Ru-Ir alloy spark plug electrode material, the mass percentage ratio of Pt 90%, Ru 1%, Ir7.5%, W1%, Ce 0.5%. The preparation method is as follows: according to the nominal composition of the alloy, the corresponding elemental metal powder with a purity of 99.95% is weighed, mixed evenly, and placed in a crucible. Put the above-mentioned crucible into the induction furnace, pass in argon gas to form a protective atmosphere, raise the temperature of the furnace tube to 1950°C, and keep it warm for 5 minutes. After the metal powder raw material is completely melted, it is directly cast into alloy waste.

Embodiment 3

[0044] A Pt-Ru-Ir alloy spark plug electrode material, the mass percentage ratio is Pt 80%, Ru 14.5%, Ir 1%, W 1%, Al 1%, Zr 1%, La 0.5%, Ce 0.5%, Nd 0.5 %. The preparation method is as follows: according to the nominal composition of the alloy, the corresponding elemental metal powder with a purity of 99.95% is weighed, mixed evenly, and placed in a crucible. Put the above-mentioned crucible into the induction furnace, pass in argon gas to form a protective atmosphere, raise the temperature of the furnace tube to 1950°C, and keep it warm for 5 minutes. After the metal powder raw material is completely melted, it is directly cast into alloy waste.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com