Grinding aid for improving early strength of Portland cement

A Portland cement and early strength technology, which is applied in the field of grinding aids for improving the early strength of Portland cement, can solve the problems of low addition amount and poor early strength effect, etc., and achieves enhanced early strength, reduced particle size, and increased ratio The effect of surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A modified water reducer used in grinding aids for improving the early strength of Portland cement, the preparation method of which is as follows:

[0034] (1) Dissolve 8.89g of alanine in 100mL of water, adjust the temperature to 0°C, add NaOH dropwise to adjust the pH value to 8, and 2 Add 9.05g of acryloyl chloride under the same conditions, stir evenly, react for 6h, distill and filter to obtain compound A;

[0035] (2) Dissolve 50g of allyl polyoxyethylene ether in 50mL of water, heat to 40°C to dissolve, add 10g of hydrogen peroxide and 20g of compound A;

[0036] (3) Dissolve 11.6g of ammonium sulfite and 13.2g of trichlorethylene in 50mL of water, mix well, slowly add dropwise to the solution in step (2), and adjust the pH value to 8 with sodium hydroxide to obtain a modified water reducer.

Embodiment 2

[0038] A modified dispersant used in grinding aids for improving the early strength of Portland cement, the preparation method of which is as follows:

[0039] Dissolve 200g of sodium bisulfite in 500mL of water, stir to dissolve, raise the temperature to 60°C, slowly add 50g of acrylic acid, 20g of ammonium persulfate and 75g of acrylate to the solution dropwise, keep the temperature constant for 4 hours to obtain a modified dispersant.

Embodiment 3

[0042] A grinding aid for improving the early strength of Portland cement, which consists of the following raw materials in parts by weight:

[0043] 18 parts of triethanolamine, 10 parts of ethylene glycol, 1.3 parts of sodium gluconate, 0.5 parts of modified water reducer, 1 part of sodium hexametaphosphate, 2 parts of tartaric acid, 0.7 parts of modified dispersant, 0.3 parts of calcium sugar, 50 parts of water share.

[0044] The preparation method of the grinding aid for improving the early strength of Portland cement comprises the following steps:

[0045] (1) Add triethanolamine and tartaric acid into water, heat to 40-50°C, and stir to dissolve;

[0046] (2) Add ethylene glycol, sodium gluconate, modified water reducer, and sodium hexametaphosphate into the solution of step (1), and stir evenly;

[0047] (3) Add the modified dispersant and sugar calcium to the solution in step (2), and mix evenly to obtain a grinding aid.

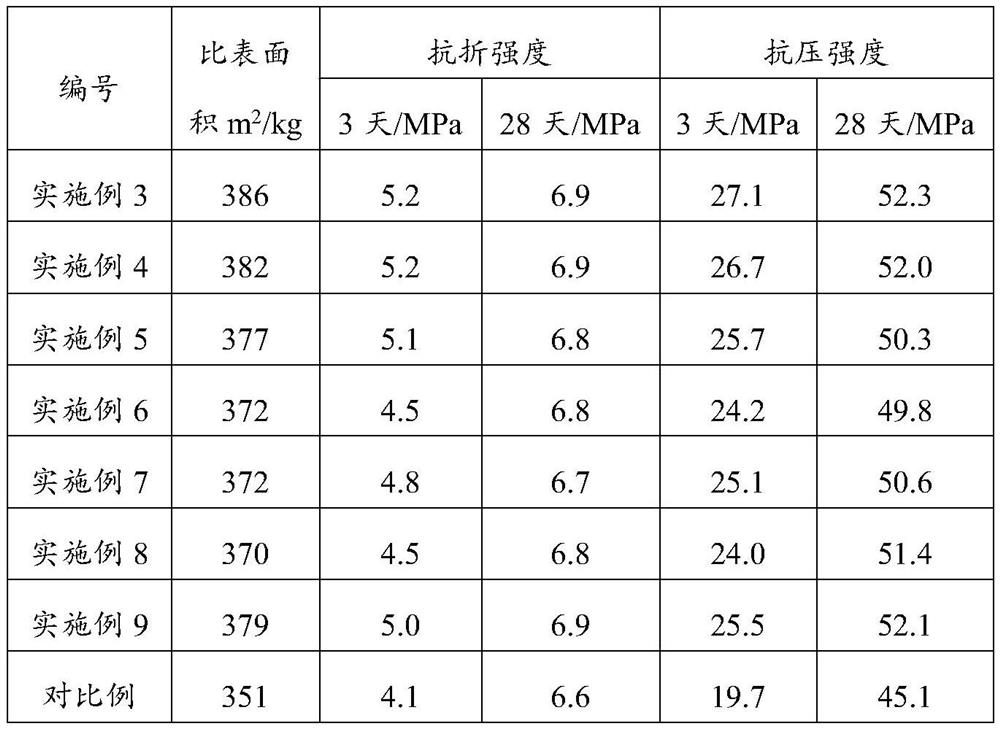

[0048] The above-mentioned grinding aid wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com