Method and apparatus for extracting, rectifying and separating propane and propylene by separated wall tower

A technology of extractive rectification and dividing wall column, which is applied in the field of separating wall column extractive rectification and separation of propane and propylene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

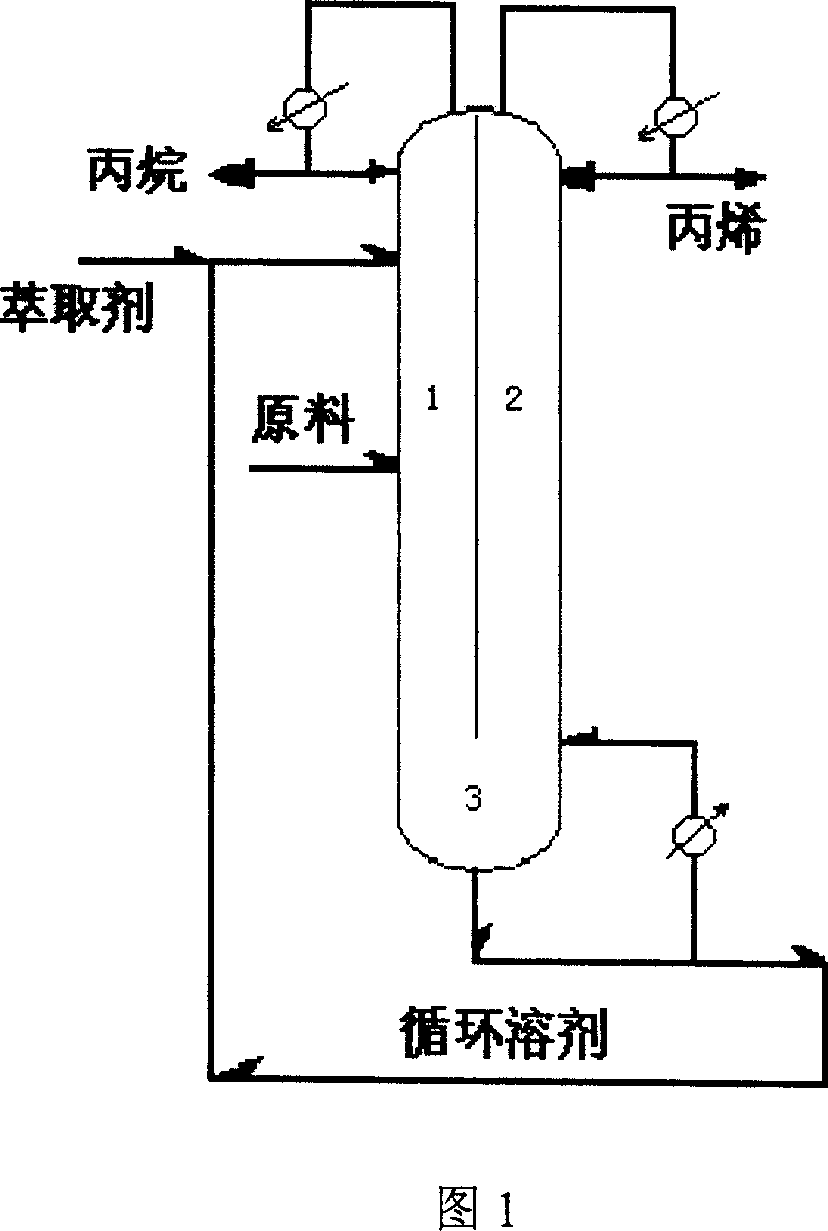

Image

Examples

Embodiment 1

[0032] Example 1: Extraction and rectification of propylene and propane using a four-tower process. The process conditions are as follows: the processing capacity is 15000t / a, the propylene content in the raw material is 70% (mol%), the operating pressure is 1.72Mpa, and the converted molar flow rate is 48.905Kmol / hr. The extractant is aqueous acetonitrile with a water content of 40% (mol%). The process parameters of each column are shown in Table 1. The separation result is: the purity of propylene is 99.3% (mol%), and the recovery rate is 93%. A total of 90 theoretical boards are required for the four-tower process. The process parameters are shown in Table 1.

[0033] project

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com