Automatic magnesium alloy low-pressure casting machine

A low-pressure casting machine and magnesium alloy technology, applied in the field of casting, can solve problems such as oxidation slag inclusions, combustion accidents, and castings are prone to shrinkage and porosity, so as to improve fluidity, eliminate defects such as shrinkage porosity and oxidized slag inclusions, Favorable effect on formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

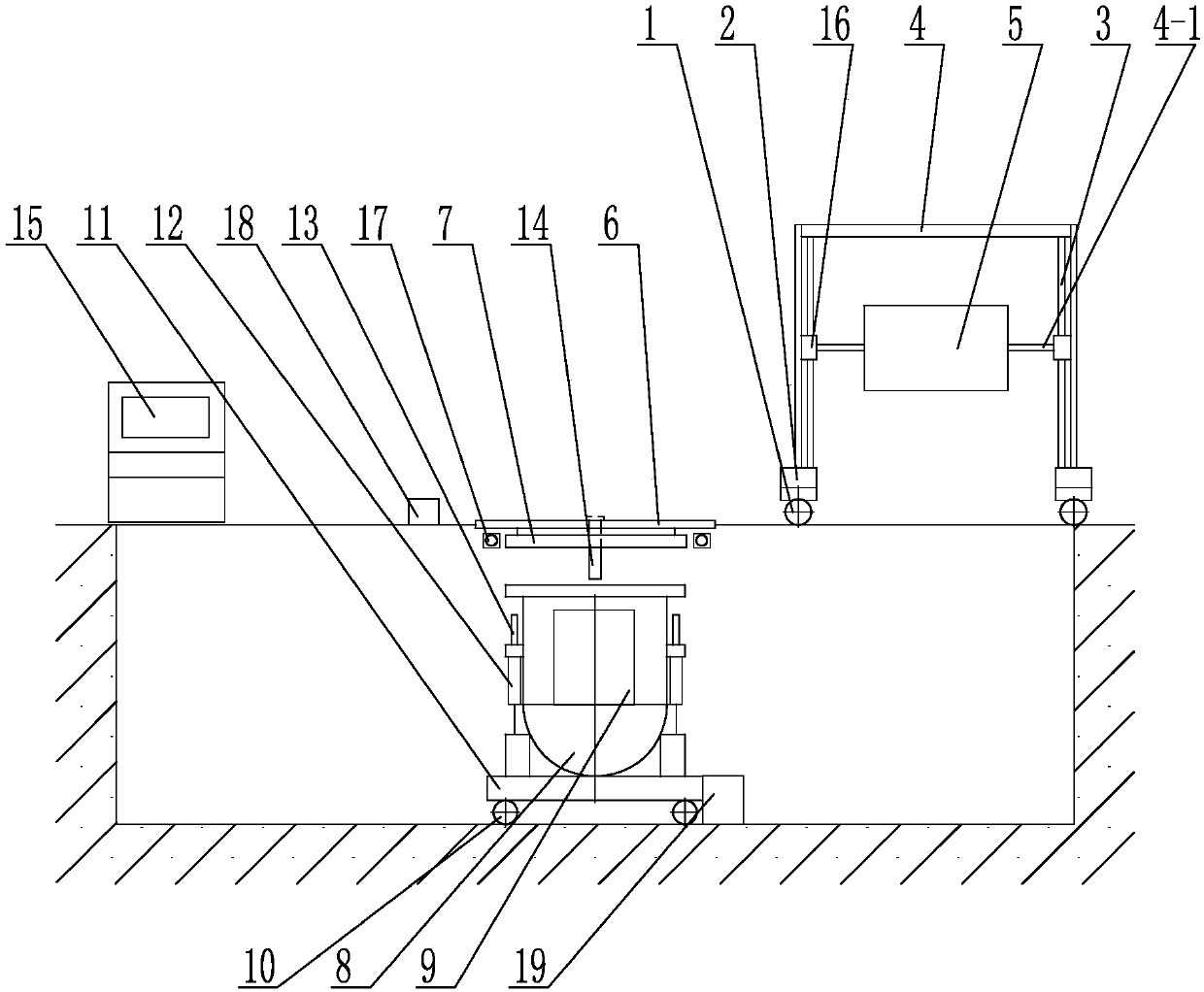

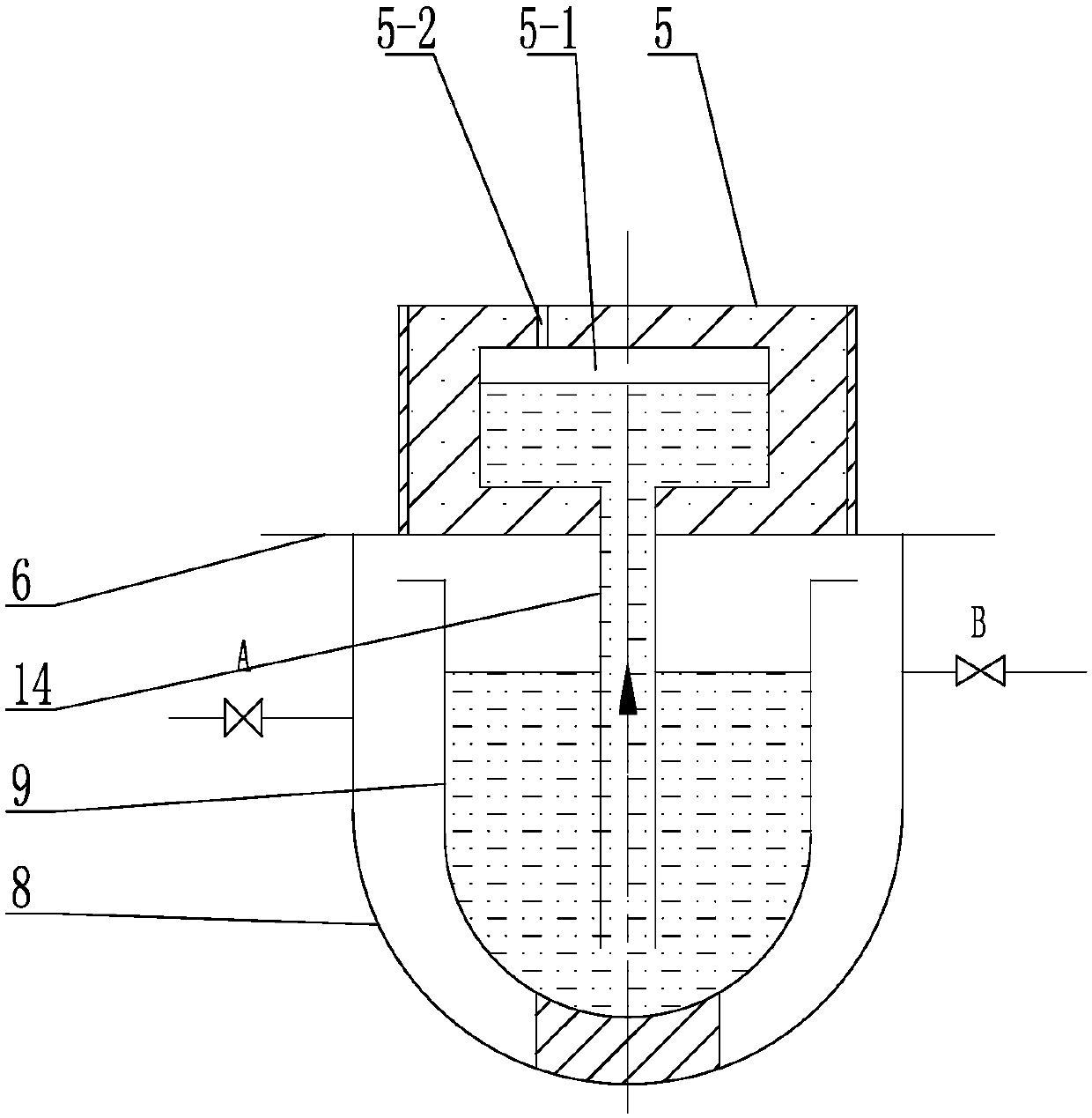

[0015] Specific implementation mode one: combine Figure 1 to Figure 2 This embodiment is described. A magnesium alloy automatic low-pressure casting machine described in this embodiment includes a mold running mechanism, a pouring platform 6, a working tank 8, a moving trolley 11 for the working tank, a riser pipe 14, and a controller 15. The running mechanism moves in the horizontal direction on the upper end of the pouring platform 6, and the casting mold 5 is carried on the casting mold running mechanism. On the cart 11, a working tank lifting mechanism is respectively provided on both sides of the working tank 8, and the working tank 8 is lifted and lowered on the working tank moving trolley 11 through the working tank lifting mechanism, and the lifting pipe 14 is inserted on the pouring platform 6 , the working tank 8 is connected with an intake pipe and an exhaust pipe, and the casting mold running mechanism, the working tank moving trolley 11 and the working tank lifti...

specific Embodiment approach 2

[0017] Specific implementation mode two: combination figure 1 Describe this embodiment, the mold running mechanism described in this embodiment includes a mold horizontal movement mechanism 1, a mold movement gantry 4 and two mold lifting mechanisms, and a mold 5 is arranged on the horizontal beam of the mold movement gantry 4 4-1, the casting mold horizontal movement mechanism 1 is arranged at the lower end of the casting mold movement gantry 4, and the vertical frames on both sides of the casting mold movement gantry 4 are respectively equipped with a mold lifting mechanism, and the horizontal beam 4-1 The two ends of the mold are connected with the mold movement gantry 4 by the mold lifting mechanism, and the mold horizontal movement mechanism 1 and the mold lifting mechanism are connected with the controller 15 respectively. The undisclosed technical features in this embodiment are the same as those in the first embodiment.

[0018] In such a design, the controller 15 con...

specific Embodiment approach 3

[0019] Specific implementation mode three: combination figure 1 Describe this embodiment, the casting mold lifting mechanism described in this embodiment comprises casting mold lifting motor 2, casting mold lifting lead screw 3 and nut 16, and casting mold lifting motor 2 is arranged on casting mold movement gantry 4, and casting mold lifting wire The bar 3 is arranged along the height direction of the casting mold movement gantry 4, the casting mold lifting motor 2 is connected with the casting mold lifting screw 3, the nut 16 is screwed on the casting mold lifting screw 3, and one side of the nut 16 is sleeved on the casting mold lifting screw 3. On the vertical frame of type motion gantry frame 4, the other side of nut 16 is affixed to the end of horizontal crossbeam 4-1, and mold lifting motor 2 is connected with controller 15. The undisclosed technical features in this embodiment are the same as those in the second embodiment.

[0020] In such a design, during the liftin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com