Polishing grinding water bath dedusting system

A dust removal system, water bath dust removal technology, applied in the direction of grinding frame, grinding bed, grinding slide, etc., can solve the problems of fire and explosion, dust absorption difficulties, etc., to achieve easy operation, excellent dust removal effect, and convenient collection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

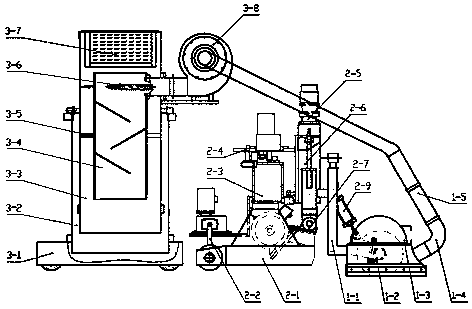

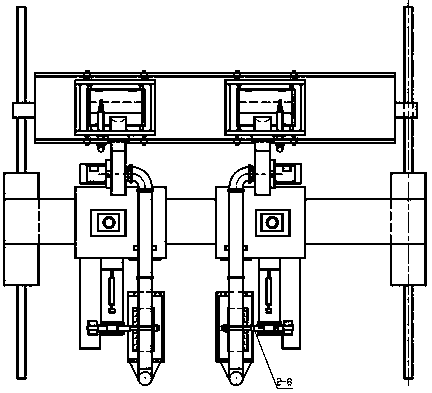

[0026] As shown in the figure, the specific implementation method is as follows:

[0027]A polishing water bath dust removal system, comprising a polishing device, a dust collection device and a water bath dust removal device, the polishing device includes a frame 2-1, and a drive frame 2-1 is also installed on the frame 2-1. The longitudinal driving mechanism 2-2 that moves along the guide rail on the foundation, the gantry main beam 2-3 is fixed on the upper part of the frame 2-1, and the gantry main beam 2-3 is installed with a slide rail perpendicular to the guide rail on the foundation. A lateral movement mechanism 2-4 is installed slidingly on the rail, and a grinding head lifting mechanism 2-6 is fixedly installed on the lateral movement mechanism 2-4, and the grinding head lifting mechanism 2-6 is supported on the lateral movement mechanism 2-4, a grinding head support 2-7 is fixed on the moving end of the grinding head lifting mechanism 2-6, and a grinding head main s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com