Hydrogen storage cylinder externally wrapped with fireproof vibration-damping thermal insulation material

A technology of thermal insulation material and hydrogen storage bottle, applied in the field of hydrogen storage bottle, can solve problems such as accelerating the release of hydrogen from hydrogen storage materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

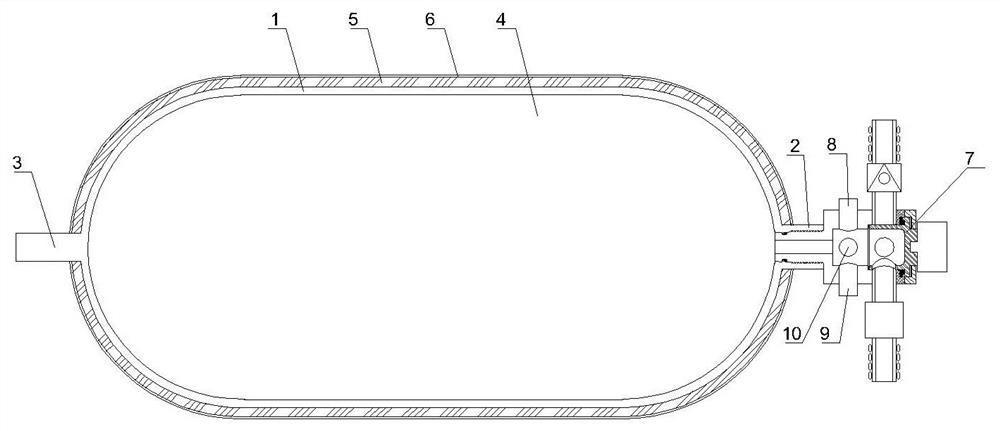

[0027] A schematic diagram of the cross-sectional structure of a hydrogen storage bottle wrapped with a fireproof, vibration-reducing, and heat-insulating material outside the inner metal bottle is shown in figure 1 As shown, among them: 1 is the metal hydrogen storage bottle, 2 is the mouth of the metal hydrogen storage bottle, 3 is the rotating seat of the metal hydrogen storage bottle, 4 is the inner cavity of the metal hydrogen storage bottle, 5 is the fireproof and vibration-reducing insulation layer, 6 is the outer Protective layer, 7 is a bottleneck valve, 8 is a temperature sensor, 9 is a pressure sensor, and 10 is a safety valve.

[0028] During production, the metal hydrogen storage bottle 1 is wrapped with a fireproof and vibration-reducing insulation layer 5, and the fireproof and vibration-damping insulation layer 5 is wrapped with an outer protective layer 6. The bottle mouth valve 7 is installed in the metal hydrogen storage bottle bottle mouth 2, and the bottle ...

Embodiment 2

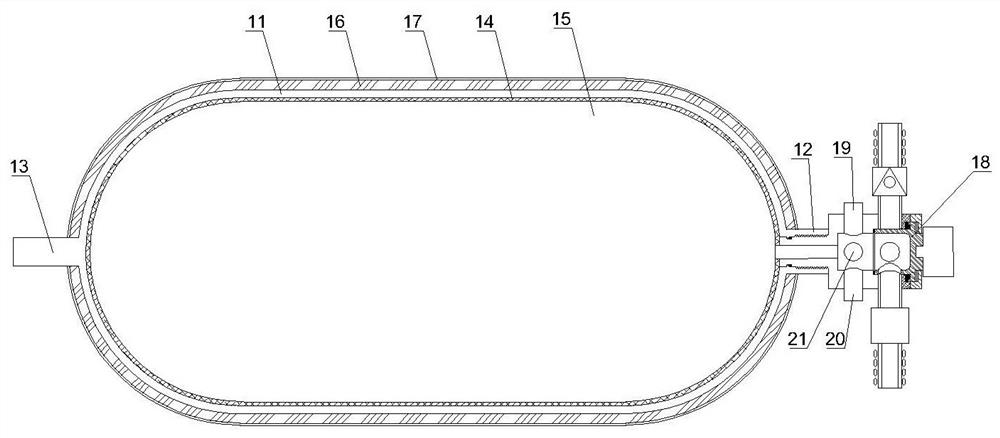

[0031] A cross-sectional structure diagram of a hydrogen storage bottle lined with a metal bottle lined with a resin layer and wrapped with a fireproof, vibration-reducing, and heat-insulating material is shown in figure 2 As shown, among them: 11 is the metal hydrogen storage bottle, 12 is the mouth of the metal hydrogen storage bottle, 13 is the rotating seat of the metal hydrogen storage bottle, 14 is the lining resin layer, 15 is the inner cavity of the metal hydrogen storage bottle, and 16 is the fire prevention and reduction Vibration insulation layer, 17 is an outer protective layer, 18 is a bottleneck valve, 19 is a temperature sensor, 20 is a pressure sensor, and 21 is a safety valve.

[0032] During production, the metal hydrogen storage bottle 11 is made with an inner resin layer 14, the metal hydrogen storage bottle 11 is wrapped with a fireproof, vibration-damping and heat-insulating layer 16, and the fire-proof, vibration-damping and heat-insulating layer 16 is w...

Embodiment 3

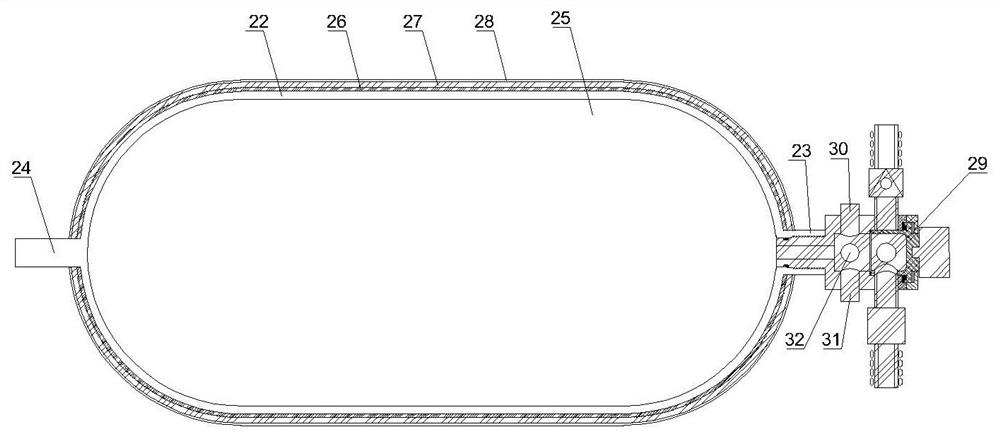

[0035] A schematic diagram of the cross-section structure of a hydrogen storage bottle wrapped with carbon fiber wrapped around a metal bottle and wrapped with carbon fiber image 3 As shown, among them: 22 is the metal hydrogen storage bottle, 23 is the mouth of the metal hydrogen storage bottle, 24 is the rotating seat of the metal hydrogen storage bottle, 25 is the inner cavity of the metal hydrogen storage bottle, 26 is glued carbon fiber, 27 is fire prevention and vibration reduction Insulation layer, 28 is an outer protective layer, 29 is a bottleneck valve, 30 is a temperature sensor, 31 is a pressure sensor, and 32 is a safety valve.

[0036] During production, the metal hydrogen storage bottle 22 is wrapped with rubberized carbon fiber 26, and the rubberized carbon fiber 26 is wrapped with a fire-proof, vibration-damping and heat-insulating layer 27, and the fire-proof, vibration-damping and heat-insulating layer 27 is wrapped with an outer protective layer 28, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com