Multi-air-chamber stratified biomass particle burner and burning method

A technology of biomass pellets and burners, applied in the field of burners, can solve problems such as insufficient combustion and easy slagging, and achieve the effects of scientific and reasonable design, high combustion efficiency, high economic value and social value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to these embodiments.

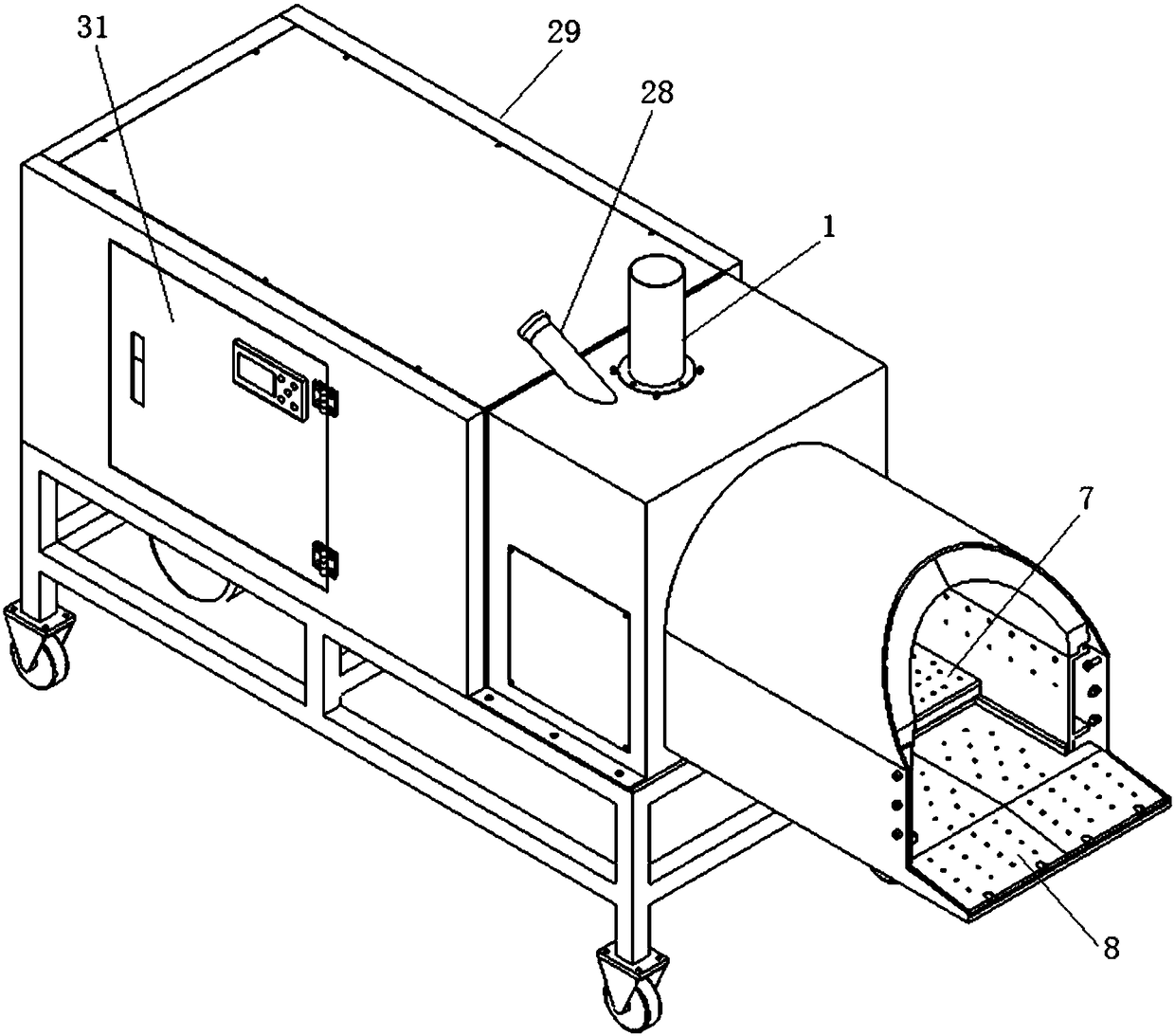

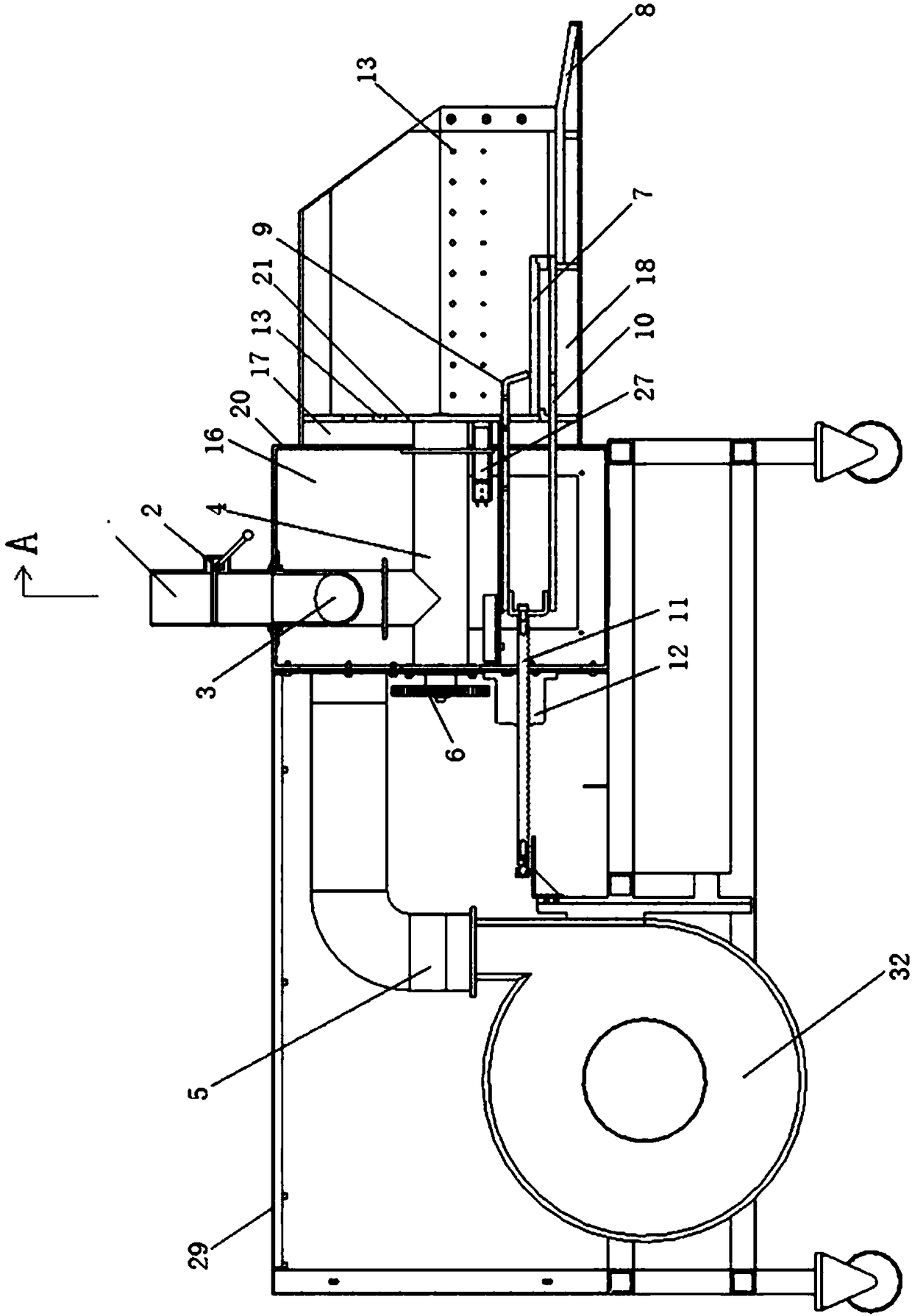

[0031] A structure of the multi-air chamber layer-type biomass pellet burner of the present invention is as follows: figure 1 Shown, mainly comprise frame 29, and frame interior is provided with feeding device, air chamber and combustion chamber.

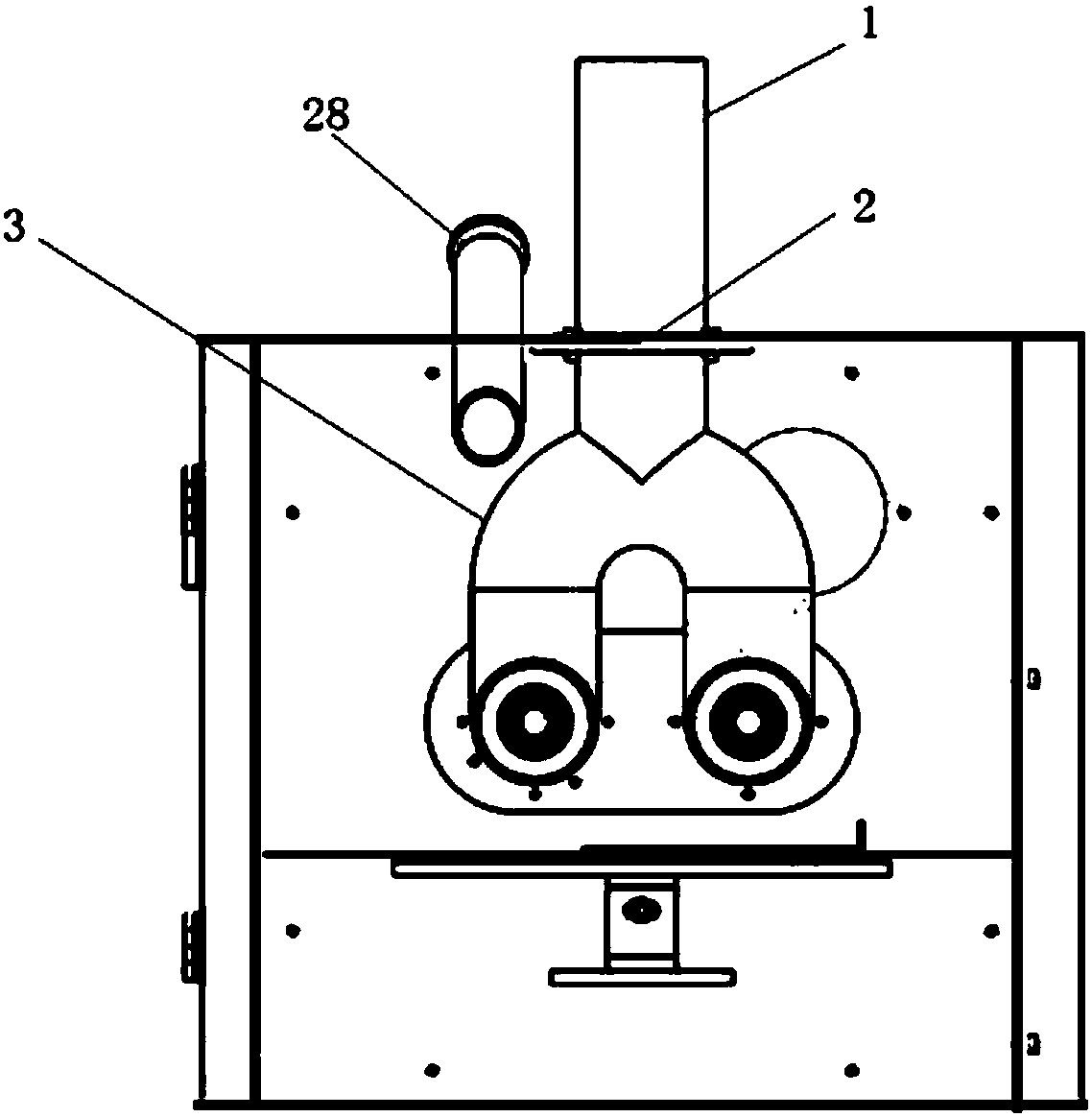

[0032] feeding device such as figure 2 , image 3 As shown, it is located in the middle and upper part of the burner. It includes a feed pipe 1 arranged vertically. The middle part of the feed pipe 1 is horizontally equipped with an anti-tempering balance flap 2. The edge of the flap is in contact with the inner wall of the feed pipe and can block the feed pipe; the flap is fixed by a rotating shaft In the feed pipe, it can be turned up and down in the feed pipe along the rotating shaft under the action of gravity (the turni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com