Method for electric generating utilizing stalks mixed burned with city life refuses

A technology of municipal solid waste and solid waste, applied in the field of using straw to burn municipal solid waste to generate electricity, can solve problems such as waste of resources, achieve the effects of improving stability, reducing dioxin emissions, and improving waste combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

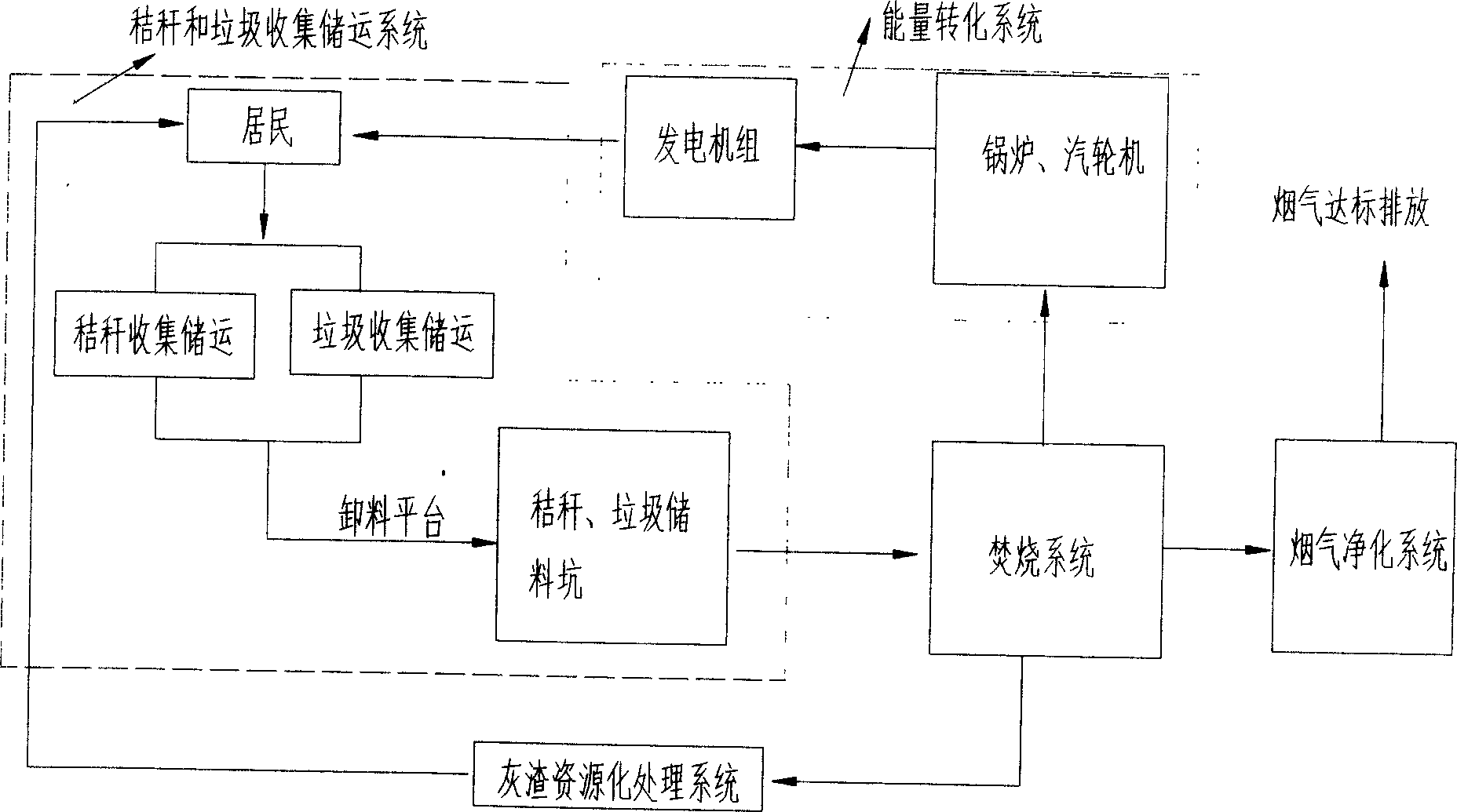

[0024] The present invention is a system for generating electricity by mixing straw and burning municipal solid waste, such as figure 1 As shown, mainly include

[0025] 1. Straw and garbage storage and transportation system: The main function is to collect, store and transport the straw and domestic garbage to the material storage pit of the incineration power plant for use.

[0026] 2. Incineration system: The straw and garbage in the storage pit are sent to the incinerator. The combustion components of the mixture in the incinerator are fully burned and converted into heat energy, and the non-combustible components are converted into ash and slag for collection and disposal.

[0027] 3. Energy conversion system, heat energy is converted into electric energy: the heat energy generated by the combustion of the mixture is absorbed into high-quality steam through the medium water, and the steam drives the steam turbine to drive the generator to generate electricity, realizing the c...

Embodiment 2

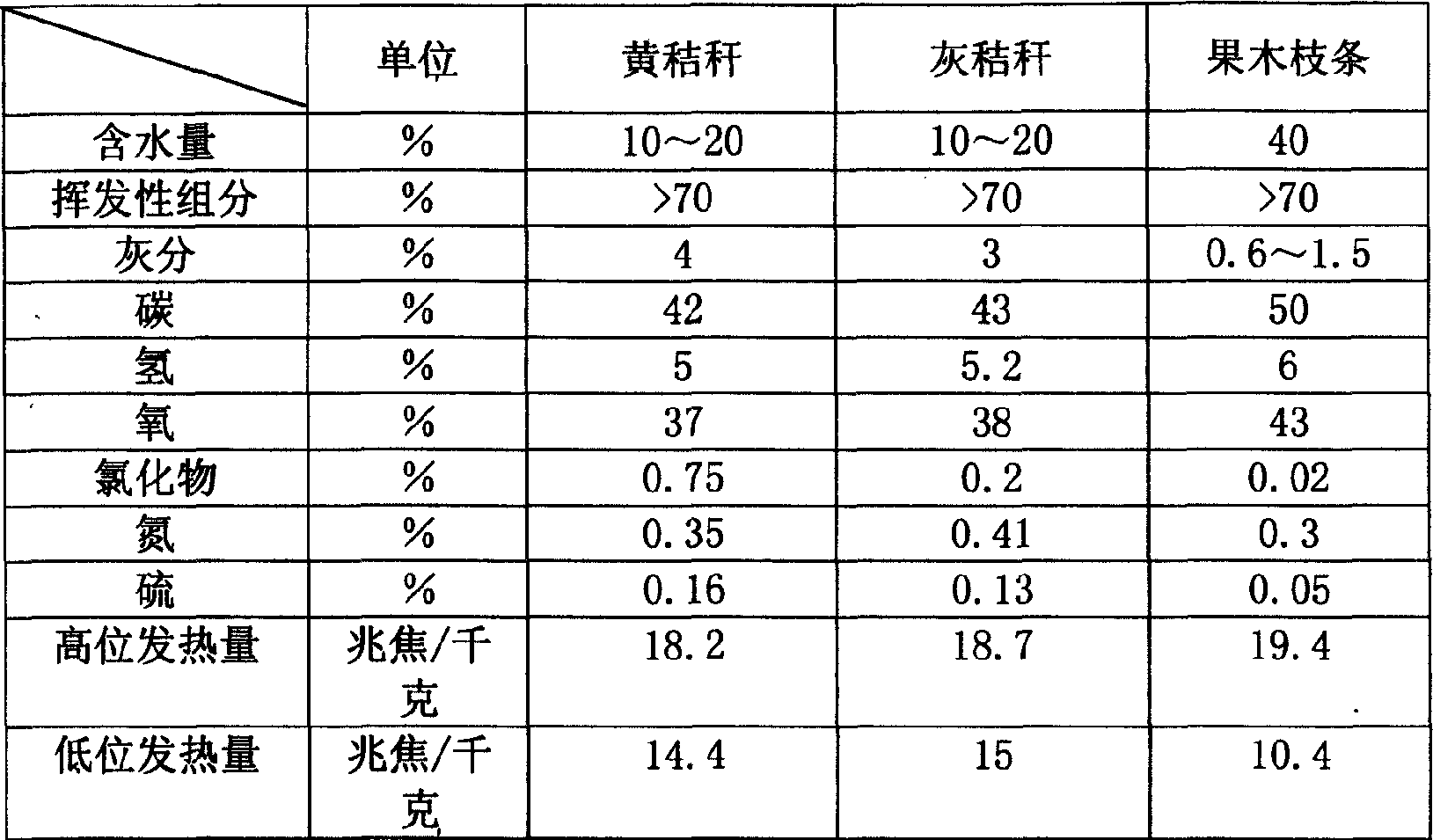

[0033] Table 1: Straw composition analysis

[0034]

[0035] According to the analysis of the straw composition in Table 1, the ratio of addition is different from that of garbage.

[0036]With the improvement of people's material living standards, the calorific value of waste will continue to increase. Therefore, the calorific value of waste is generally higher than the current design of incineration power generation equipment. When the quality of the waste is good, such as leaves, paper, plastic waste, a small amount of wheat straw, rice straw, etc. are mixed to increase the calorific value of the waste. The ratio of mixed burning of straw is generally 0.01%-10%, and the combustion temperature in the furnace is normal. Keep it at around 1000℃-1200℃. In this way, the efficient operation of incineration power generation equipment can be ensured. At the same time, the waste burnout rate can be increased, the waste ash reduction rate can be reduced, and higher...

Embodiment 3

[0038] Garbage moisture content, ash content and garbage composition are the main factors affecting garbage combustion. When the quality of garbage is not good, generally speaking, it is the garbage with high lime content or high moisture content or both, such as rotting vegetable leaves, dust particles, swill and other domestic garbage. Lime soil will increase the compactness of the garbage, which will put a lot of pressure on the primary air inlet of the grate, which will affect the primary air entering the furnace. The opening of the primary air door is generally around 90%, and sometimes it is not even 100%. It can fully meet the demand of air volume. Adopting an appropriate amount of straw to mix with garbage can effectively solve the problem. According to the amount of ash soil, the ratio of mixed burning of straw is generally about 10% to 30%. Straw and garbage are mixed into the incinerator. Due to the good support of the straw, the fluffiness of the overall mixed combusti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com