Method for purging condensate from a charge air cooler

An air cooler, condensate technology used in electrical control, exhaust gas recirculation, machine/engine, etc., to solve problems such as increased component cost and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

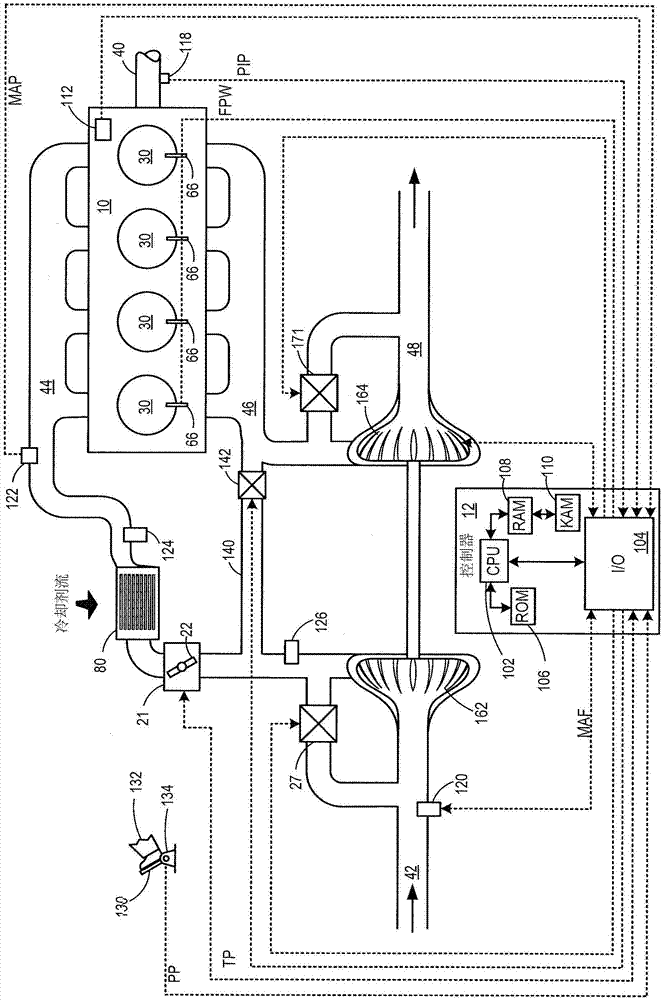

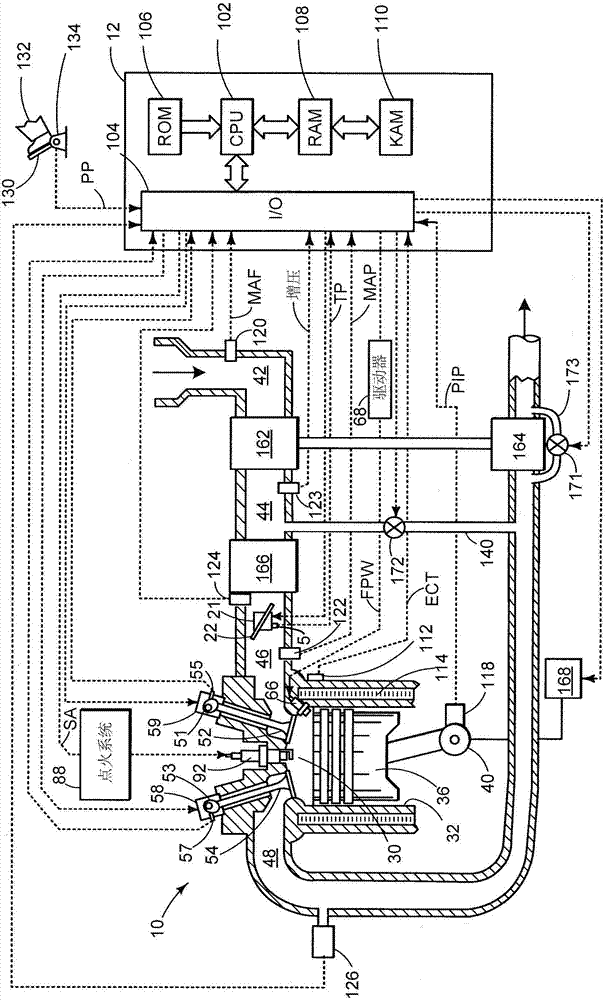

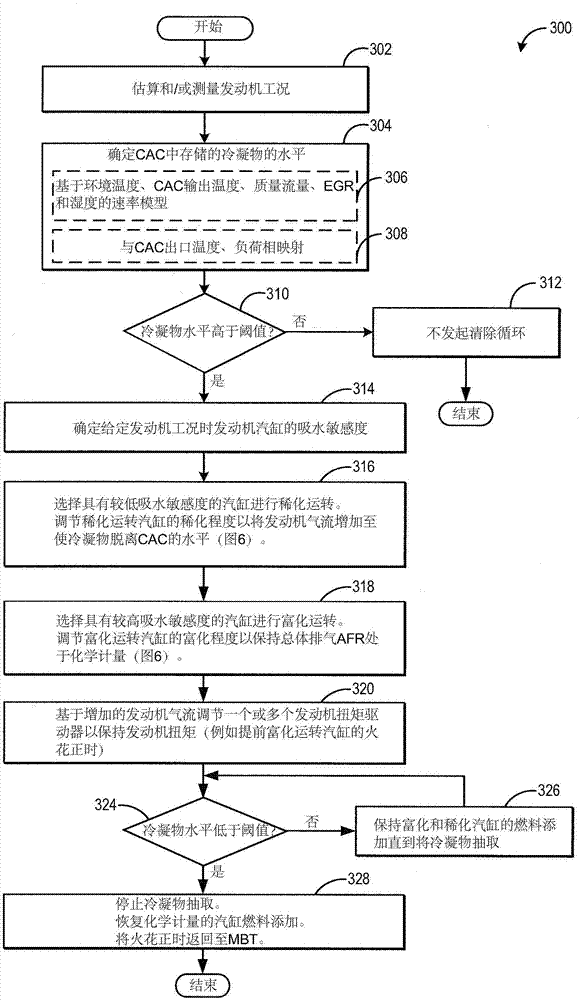

[0029] The following description refers to the extraction of condensate from the charge air cooler (CAC) to engine systems such as Figure 1-2 System and method in the system). During purging, engine airflow may be temporarily increased while engine actuators (such as spark timing) are adjusted in response to condensate flow. CAC condensate purging may occur in response to elevated condensate levels. The engine controller can be configured to execute control programs such as image 3 procedure in ) to adjust per-cylinder fueling during purging based on each cylinder's water absorption sensitivity ( Figure 5 ). Alternatively, the controller can execute Figure 4 The example routine in to adjust fuel injection timing to provide a lean stratified mode of cylinder combustion. The controller can operate one or more cylinders rich and run others lean by adjusting the degree of richness and leanness to maintain exhaust emissions ( Figure 6-8 ). In any event, engine airflow i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com