Methods and systems for resistive particulate matter sensors

A particulate matter and sensor technology, which is applied in chemical instruments and methods, separation methods, particle and sedimentation analysis, etc., can solve the problems of reducing the sensitivity of soot sensors, corroding electrodes, and sensor gain offset, so as to reduce the corrosion of soot sensors , reduced warranty costs, and reduced gain offset effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

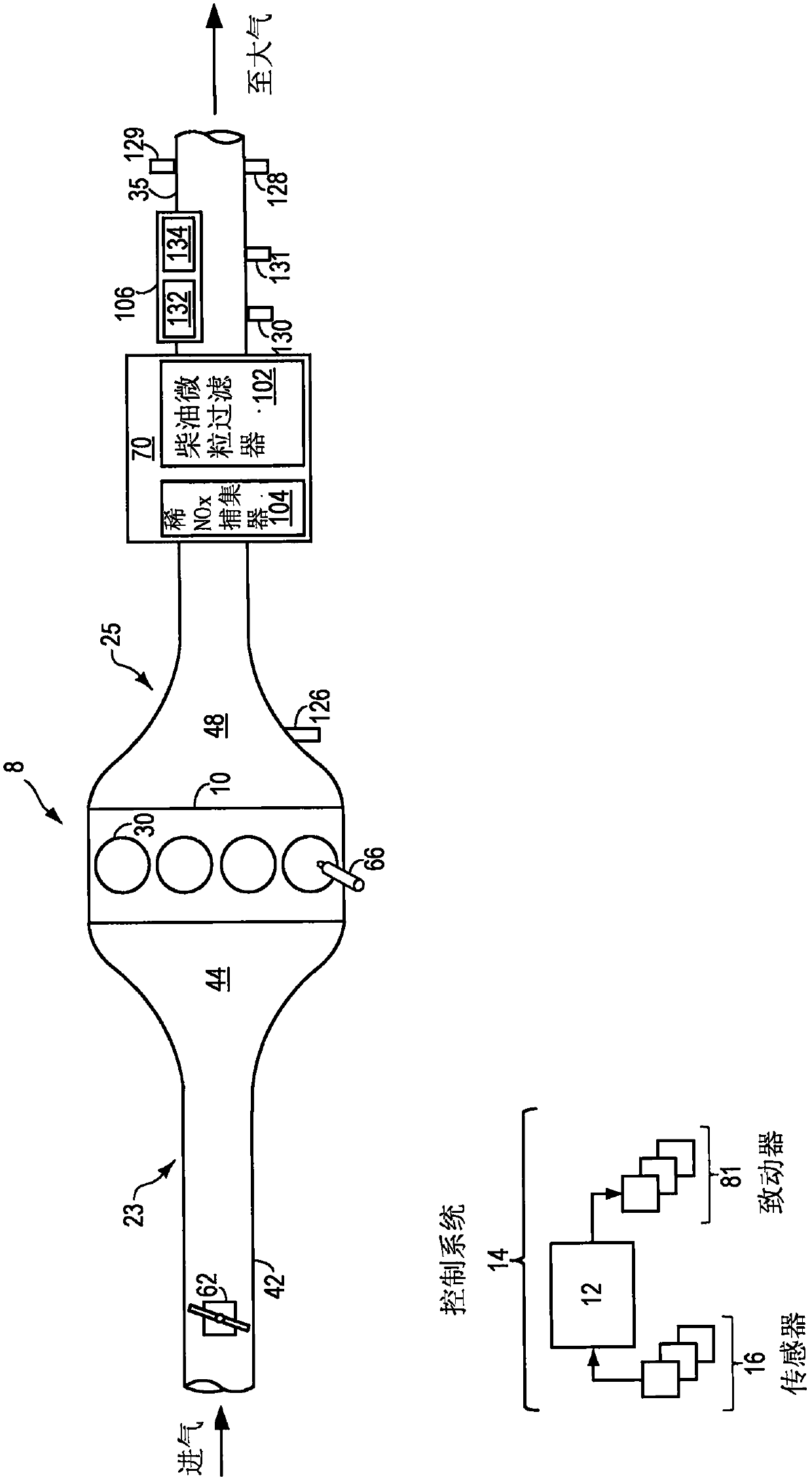

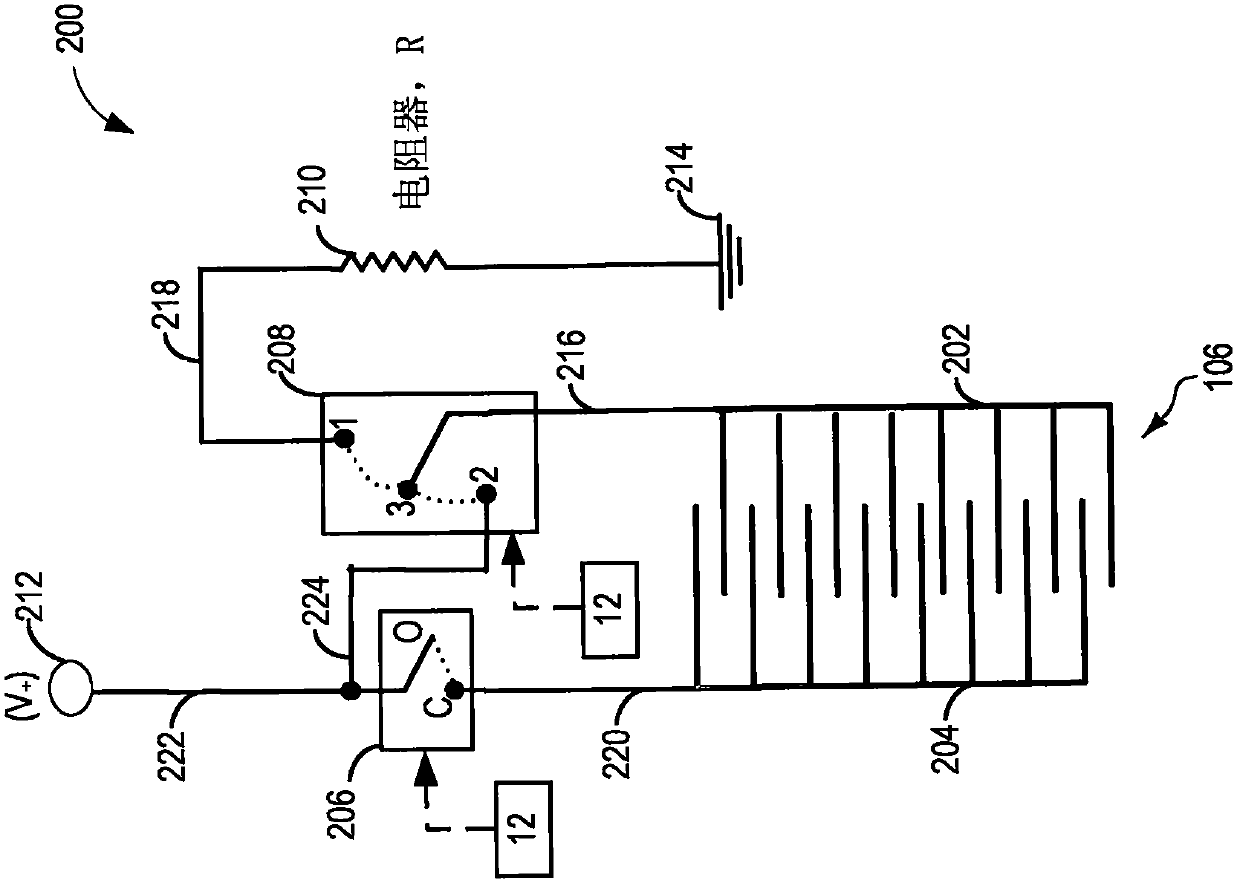

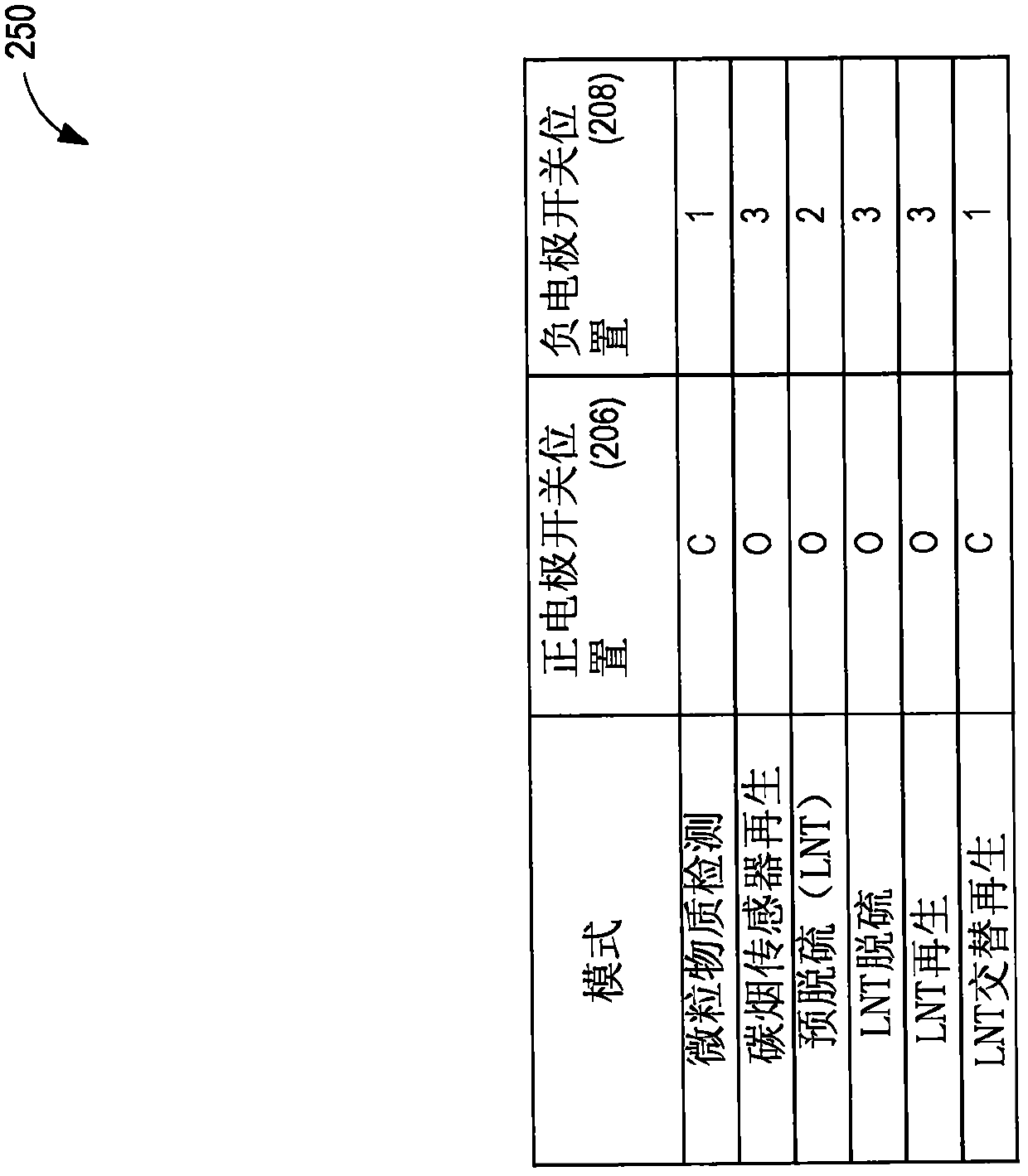

[0019] The following instructions refer to operating the engine system (as in figure 1 Systems and methods for a particulate matter (PM) sensor or a soot sensor in an engine exhaust line downstream of a lean NOx trap (LNT) in an engine system of an engine system. A PM sensor configured with a pair of interdigitated electrodes can be Figure 2A to Figure 2B The multiple switches shown in are connected to positive voltage and ground. The controller can be configured to execute programs (eg, image 3 program) to change the switch position of the soot sensor in LNT and soot sensor based operation mode. The controller can also be configured to execute programs (eg, Figure 4 program) to operate the soot sensor in the particulate matter detection mode and regenerate the soot sensor based on the soot load on the soot sensor. Additionally, the controller may intermittently estimate the exhaust NOx level and SOx level of the LNT and execute routines (eg, Figure 5 program) to rege...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com