Electricity generated by mixing and burning garbage and methane prepared by using mud and comprehensive utilization method thereof

A biogas and garbage technology, which is applied in combustion methods, sludge treatment, biological sludge treatment, etc. Pollution and other problems, to achieve the effect of solving unstable combustion, reducing the emission of harmful substances, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

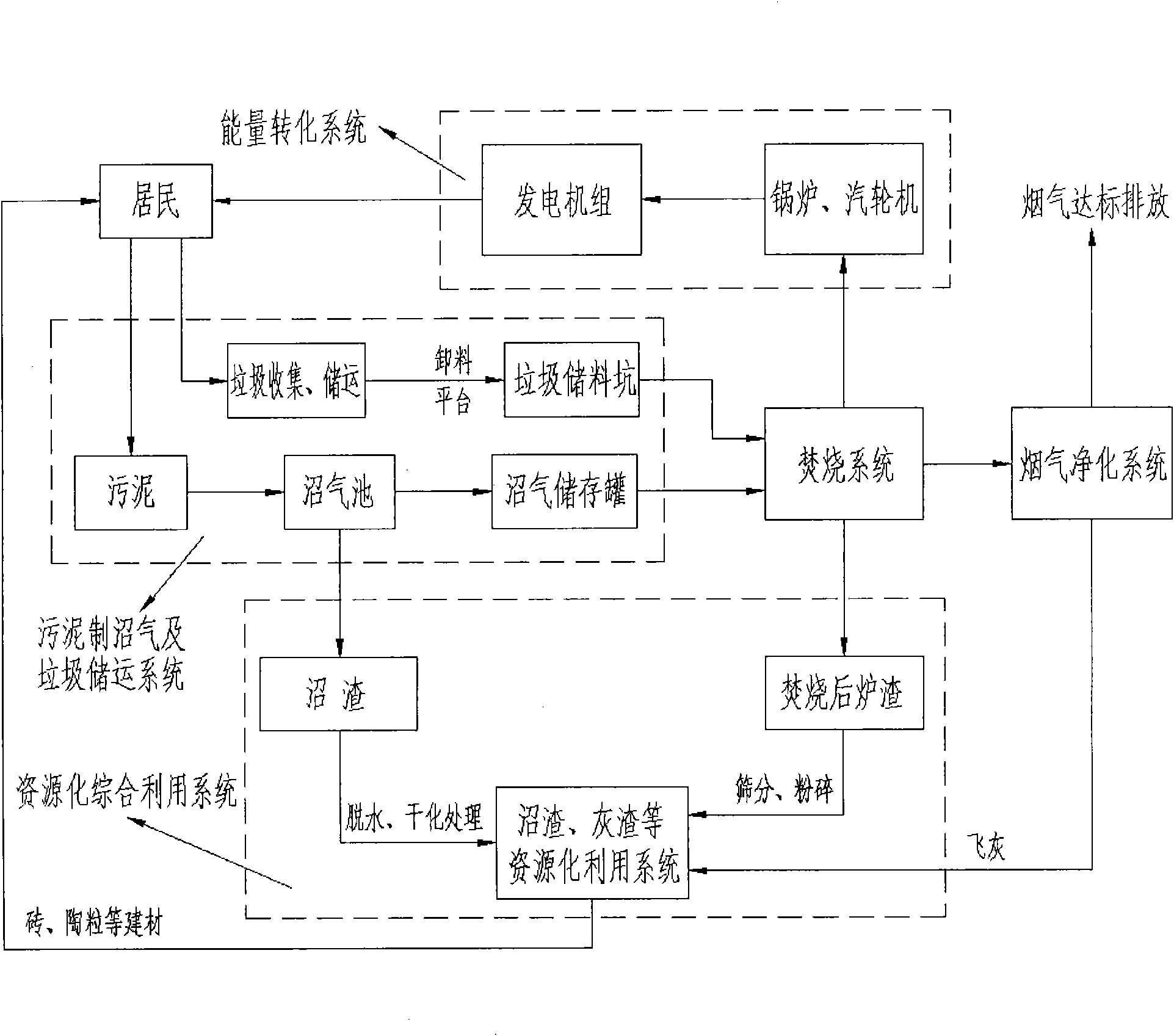

[0032] The present invention is a system for making biogas from sludge and co-combustion of garbage to generate electricity and its comprehensive utilization. As shown in the figure, it mainly includes:

[0033] 1. Sludge biogas production and garbage storage and transportation system: the sludge is mainly mixed, digested and transported to the biogas digester of the incineration power plant to obtain biogas and stored in storage tanks for later use; domestic waste is collected, stored and transported to the incineration power plant The material storage pit is ready for use.

[0034] 2. Incineration system: The fermented garbage in the storage pit and the biogas in the storage tank are sent to the incinerator for combustion. In the incinerator, the combustion components of the mixed materials are fully burned and converted into heat energy, and the non-combustible components are converted into ash and slag for discharge. post-collection processing.

[0035] 3. Energy conversi...

Embodiment 2

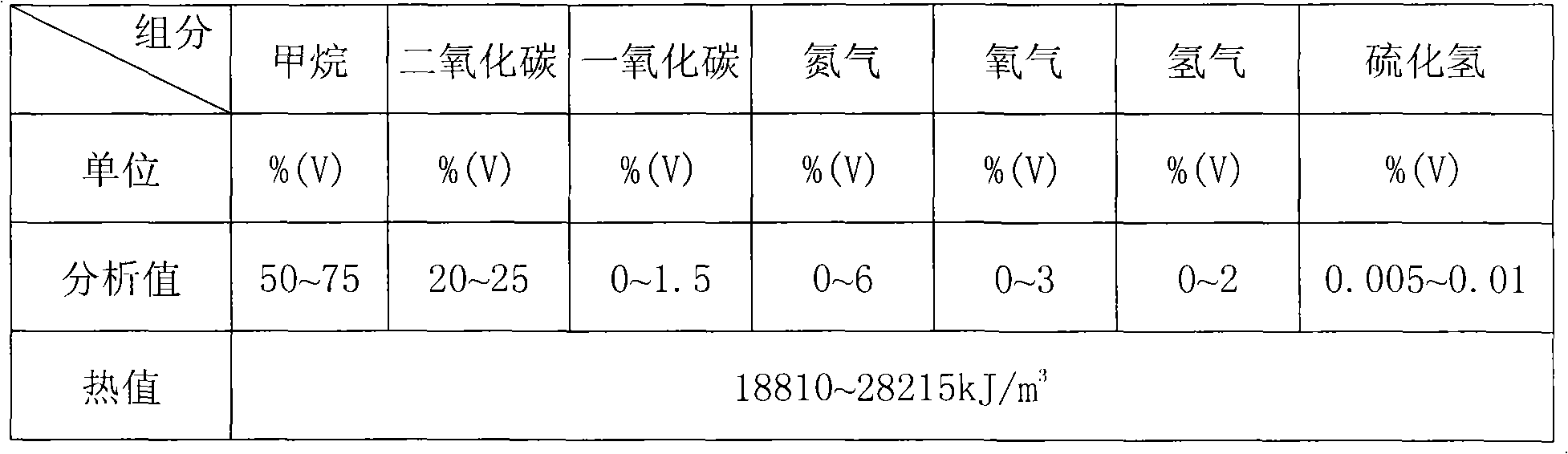

[0040] Table 1: Composition analysis of biogas produced from general sludge

[0041]

[0042] According to the biogas composition analysis in Table 1, the added ratio is different from the waste composition.

[0043] With the improvement of people's material living standards, the calorific value of waste will also continue to increase, so incineration power generation equipment is generally designed with a higher calorific value of waste than the current one. When the garbage quality is good, such as leaves, paper, plastic garbage, a small amount of biogas is introduced, generally 50-500m 3 Biogas / t waste, at this time, the combustion temperature in the furnace is generally maintained at around 850°C to 1300°C. In this way, the high-efficiency operation of incineration power generation equipment can be ensured, and at the same time, the waste burning rate can be improved, the thermal ignition loss rate of waste ash can be reduced, and higher emission standards can be obtai...

Embodiment 3

[0045] The moisture content of garbage, the content of ash and soil and the composition of garbage are the main factors affecting the combustion of garbage. When the quality of the garbage is not good, generally speaking, the garbage has a high dust content or a high moisture content or both, such as rotten vegetable leaves, dust particles, swill and other domestic garbage. At this time, the combustion situation of the garbage deteriorates sharply, which may lead to flameout. The problem can be solved by adding biogas, and the amount of biogas added is controlled according to the components of the garbage. At this time, the amount of biogas added is generally 200-500m 3 For biogas / t of waste, the combustion temperature is generally maintained at 850°C to 1100°C, so as to ensure efficient and full combustion of waste and discharge up to the standard.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com