Oil gun capable of combusting various fuel oil

An oil gun and gun barrel technology is applied in the field of fuel oil preparation to achieve the effects of improving fuel efficiency and saving fuel costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is implemented like this:

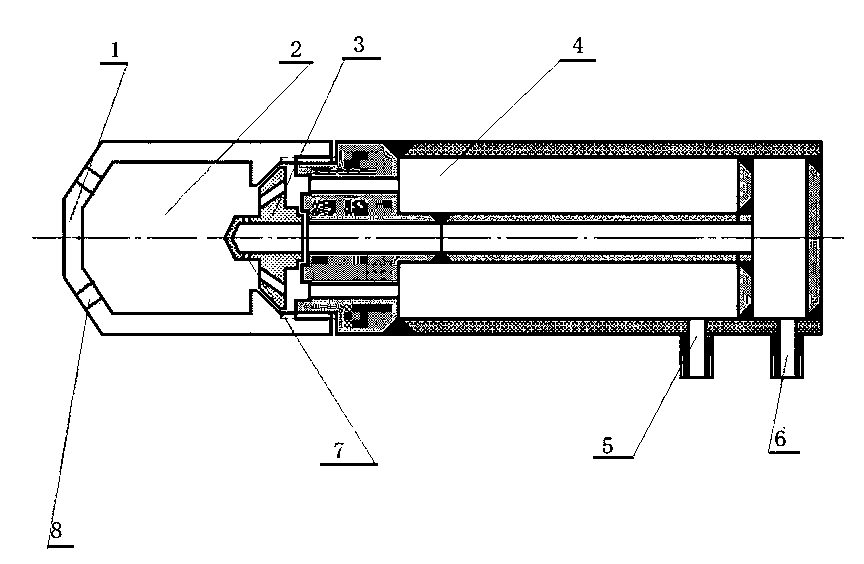

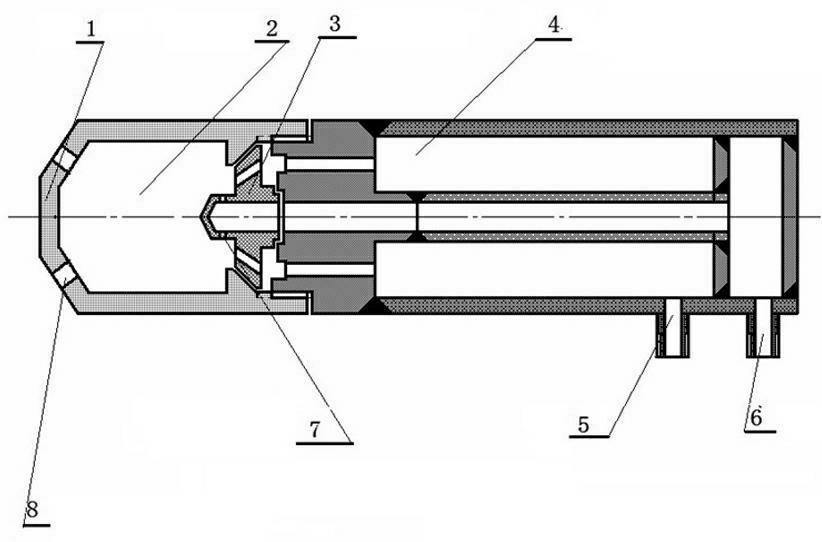

[0021] A gas explosion atomization oil gun, which includes a nozzle 1 and a gun barrel 4, an oil-gas distributor 3 is arranged between the nozzle 1 and the gun barrel 4, and the oil-gas distributor 3 is provided with a first-stage swirl atomizer 7, the nozzle 1 is provided with a second-stage gas explosion atomization nozzle 8, the nozzle 1 and the oil-gas distributor 3 form a bubble generation chamber, the gun barrel 4 is provided with an air inlet 5 and an oil inlet 6, and the fuel is fed from After the oil inlet 6 enters the oil gun, it reaches the first-stage swirl atomization sheet 7, realizing the first-stage swirl mechanical atomization, and the fuel is initially crushed to form fine oil particles that are sprayed into the bubble generation chamber 2, realizing the first stage atomization; the pressurized gas entering from the air inlet 5 passes through the gun barrel 4, and then enters the bubble generation chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com