Method for preparing huge dual-side flexible aluminum foil by spraying compound solution through atomizing and powder-spraying device

A compound solution and powder spreading device technology, which is applied in the direction of solid-state chemical plating, metal material coating technology, coating, etc., can solve the problems of difficult control of processing uniformity and restrictions on the application of PTC materials, so as to improve production efficiency and excellent Product rate, strong consistency of product thickness, and simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

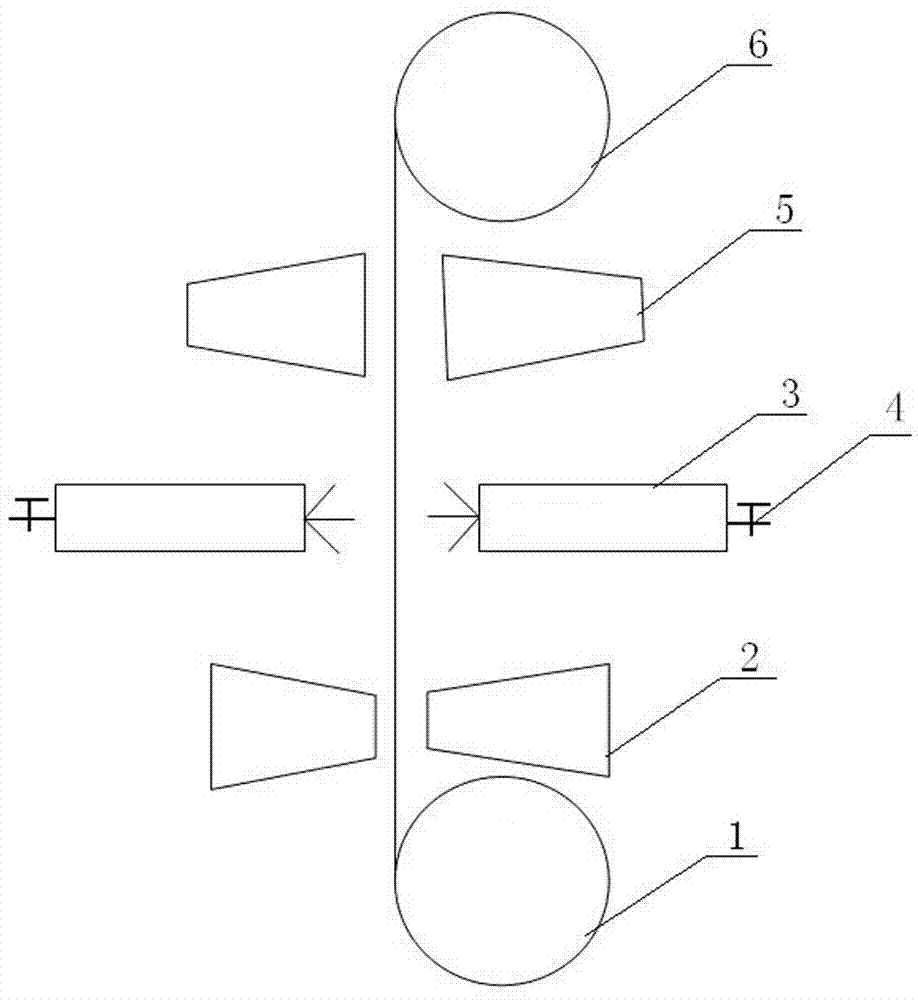

[0022] Such as figure 1 所示,本实施例雾化撒粉装置喷撒复合溶液制备巨幅双面挠性铝箔的方法,包括以下步骤:(1)制备复合溶液:取氨基丙烷93g,溶于1000g甲基酰胺中制备溶液,该溶液用水浴冷却,氮气保护下依次加入联苯酸酐73.7g,将混合液恢复到室温,持续搅拌3小时,进行聚合反应,得到粘稠的热塑性聚酰亚胺树脂前驱体溶液,将140g碳纤维添加到以上溶液中在超声波中超声并搅拌两小时,制得复合溶液,(2)将厚度为5μm的电解铝箔经放卷装置1放出,通过加热装置2将放出的电解铝箔加热至100°C,在幅宽1.3米,长16米的雾化撒粉装置3上,以50米 / 分钟的速度连续喷撒600米,通过雾化撒粉装置上设置的流量控制阀4控制复合溶液的流量,使固化的涂布层厚度为2.5μm,经冷却装置5冷却,然后进入收卷装置6,完成聚酰亚胺树脂复合PTC的溶液在电解铝箔上的双面喷涂;(3)将收卷装置中的电解铝箔卷取出装在50米长的龙窑中,依次经历160℃,200℃,250℃,300℃, 350℃进行加热,每个温度区各10分钟,完成亚酰胺化,经紫外光交联反应制得卷装600米长,幅宽1.3米,厚度为10μm的巨幅双面挠性电解铝箔。

Embodiment 2

[0024] 本实施例雾化撒粉装置喷撒复合溶液制备巨幅双面挠性铝箔的方法,包括以下步骤:(1)制备复合溶液:取氨基丙烷93g,溶于1000g甲基酰胺中制备溶液,该溶液用水浴冷却,氮气保护下依次加入联苯酸酐73.7g,将混合液恢复到室温,持续搅拌3小时,进行聚合反应,得到粘稠的热塑性聚酰亚胺树脂前驱体溶液,将140g炭黑添加到以上溶液中在超声波中超声并搅拌两小时,制得复合涂布液,(2)将厚度为3μm的电解铝箔经放卷装置放出,通过加热装置将放出的电解铝箔加热至150°C,在幅宽1.3米,长16米的等离子涂布机上,以50米 / 分钟的速度连续喷撒600米,通过雾化撒粉装置上设置的流量控制阀控制复合溶液的流量,使固化的涂布层厚度为1μm,经冷却装置冷却,然后进入收卷装置,完成聚酰亚胺树脂复合PTC液体在电解铝箔上的双面喷涂;(3)将收卷装置中的电解铝箔卷取出装在50米长的龙窑中,依次经历160℃, 200℃, 250℃, 300℃, 350℃进行加热,每个温度区各1分钟,完成亚酰胺化,经紫外光交联反应制得卷装600米长,幅宽1.3米,厚度为5μm的巨幅双面挠性电解铝箔。

Embodiment 3

[0026] 本实施例雾化撒粉装置喷撒复合溶液制备巨幅双面挠性铝箔的方法,包括以下步骤:(1)制备复合溶液:取氨基丙烷93g,溶于1000g甲基酰胺中制备溶液,该溶液用水浴冷却,氮气保护下依次加入联苯酸酐73.7g,将混合液恢复到室温,持续搅拌3小时,进行聚合反应,得到粘稠的热塑性聚酰亚胺树脂前驱体溶液,将100g石墨片添加到以上溶液中在超声波中超声并搅拌两小时,制得复合溶液,(2)将厚度为70μm的热压铝箔经放卷装置放出,通过加热装置将放出的热压铝箔加热至250°C,在幅宽1.3米,长16米的雾化撒粉装置上,以50米 / 分钟的速度连续喷撒600米,通过雾化撒粉装置上设置的流量控制阀控制复合溶液的流量,使固化的涂布层厚度为10μm,经冷却装置冷却,然后进入收卷装置,完成聚酰亚胺树脂复合PTC液体在热压铝箔上的双面喷涂;(3)将收卷装置中的热压铝箔卷取出装在50米长的龙窑中,依次经历160℃, 200℃, 250℃, 300℃, 350℃进行加热,每个温度区各20分钟,完成亚酰胺化,经红外交联反应制得卷装600米长,幅宽1.3米,厚度为90μm的巨幅双面挠性热压铝箔。

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com