Membrane separation method and device for recycling hydrogen from purge gas of synthetic ammonia liquid ammonia storage tank

A technology for releasing gas and membrane separation, applied in hydrogen separation, using solid contact hydrogen separation, etc., can solve the problems of poor effect, can not guarantee the safety of membrane use, poor technical and economical, low pressure, etc., to ensure long-term stable operation , to ensure the stability of the device operation, to ensure the effect of not being damaged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

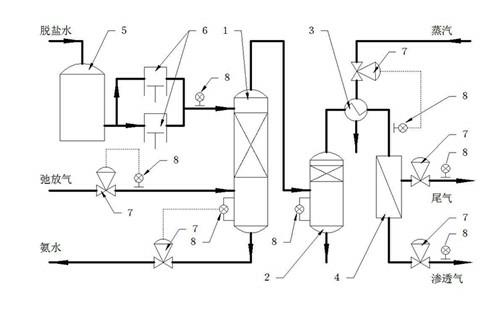

[0037] The vented gas from the liquid ammonia storage tank first enters the low-pressure high-efficiency packed ammonia absorption tower 1, where the gas contacts with the desalted water pumped in by the water pump 6 countercurrently in the packing layer, and the ammonia (NH 3) is absorbed by water and becomes ammonia water, which is discharged from the bottom of the tower. The deammoniated gas is discharged from the top of the tower and then enters the gas-liquid separator 2, so that the mist entrainment generated during the water washing process is separated. The purpose of water washing is mainly to purify the vent gas of the liquid ammonia storage tank, remove the ammonia therein, so that the residual ammonia content meets the safety requirements of the membrane separator 4, and the ammonia content of the gas after washing should be lower than 20ppm. The gas from the top of the tower is usually around 25°C. The gas-liquid two-phase balance in the water washing process mak...

Embodiment 2

[0042] The purge gas is heated to 55° C. in a heater, and the specific implementation is the same as in Example 1.

[0043] After testing, the hydrogen recovery rate of the present invention reaches 93.66%, and the hydrogen mole fraction of the recovered gas reaches 89.57%. The specific data are shown in Table 2.

[0044] Table 2

[0045]

[0046] It can be concluded from the test data that it is completely feasible to recover the hydrogen in the vent gas of the liquid ammonia storage tank by the membrane separation method, and the investment payback period is less than 3 months. Promotion and application value.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com