Formaldehyde-free zero-carbon environmentally-friendly board synthetized by circuit board and manufacture technology thereof

A manufacturing process and board powder technology, which is applied in the field of environmentally friendly boards, can solve problems such as bubbling and board bursting, and achieve the effects of reducing costs, improving efficiency, and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

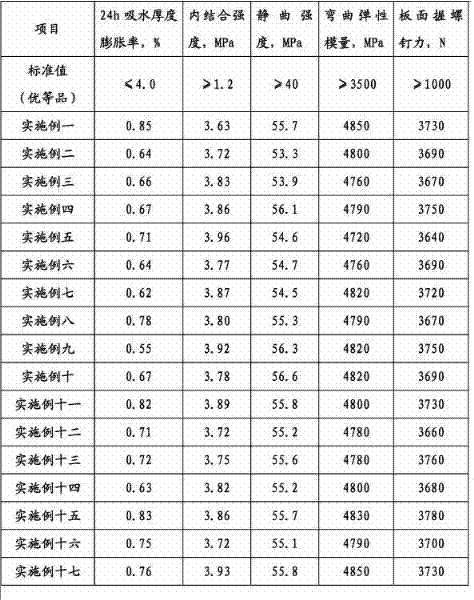

Examples

Embodiment 1

[0065] Embodiment 1: The pressing raw material of the formaldehyde-free zero-carbon environmental protection plate of the present invention includes components in the following weight ratio: 97 parts of circuit board powder, 3 parts of isocyanate, 1 part of paraffin, and 4 parts of water.

Embodiment 2

[0066] Embodiment 2: The pressing raw material of the aldehyde-free zero-carbon environmental protection board of the present invention includes components in the following weight ratio: 97 parts of circuit board powder, 20 parts of isocyanate, 5 parts of paraffin, and 8 parts of water.

Embodiment 3

[0067] Embodiment 3: The pressing raw material of the formaldehyde-free zero-carbon environmental-friendly board of the present invention includes components in the following weight ratio: 50 parts of circuit board powder, 8 parts of isocyanate, 3 parts of paraffin, and 1 part of water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com