Ultra-low calorific value gas burner

A technology of gas burner and calorific value, which is applied in the direction of gas fuel burner, burner, combustion method, etc., which can solve the problems of mutual leakage, large device volume, complex system operation, etc., and achieve the effect of stable combustion and avoiding fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

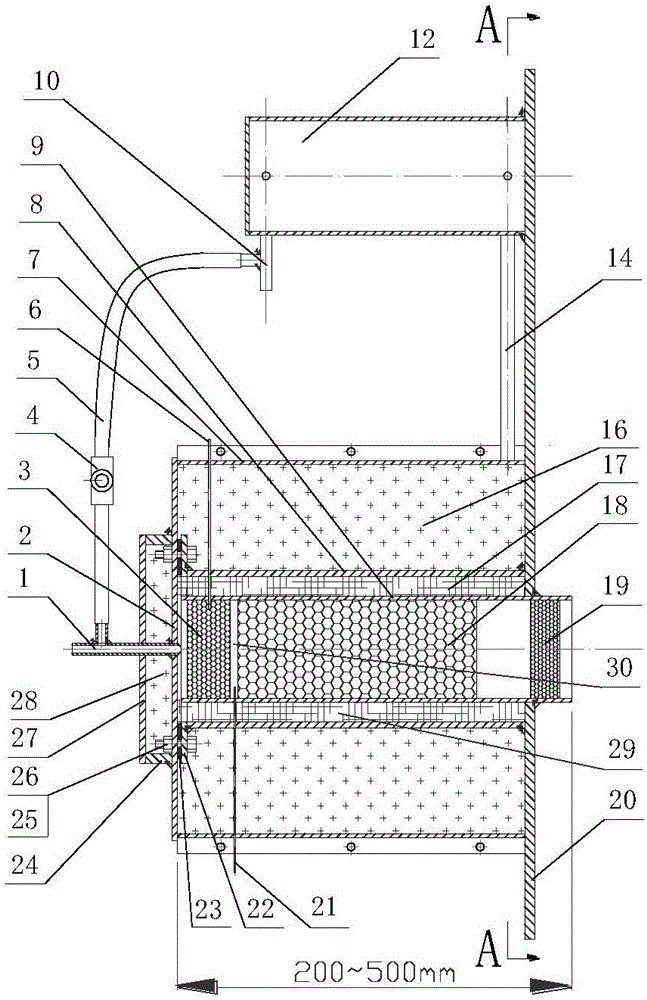

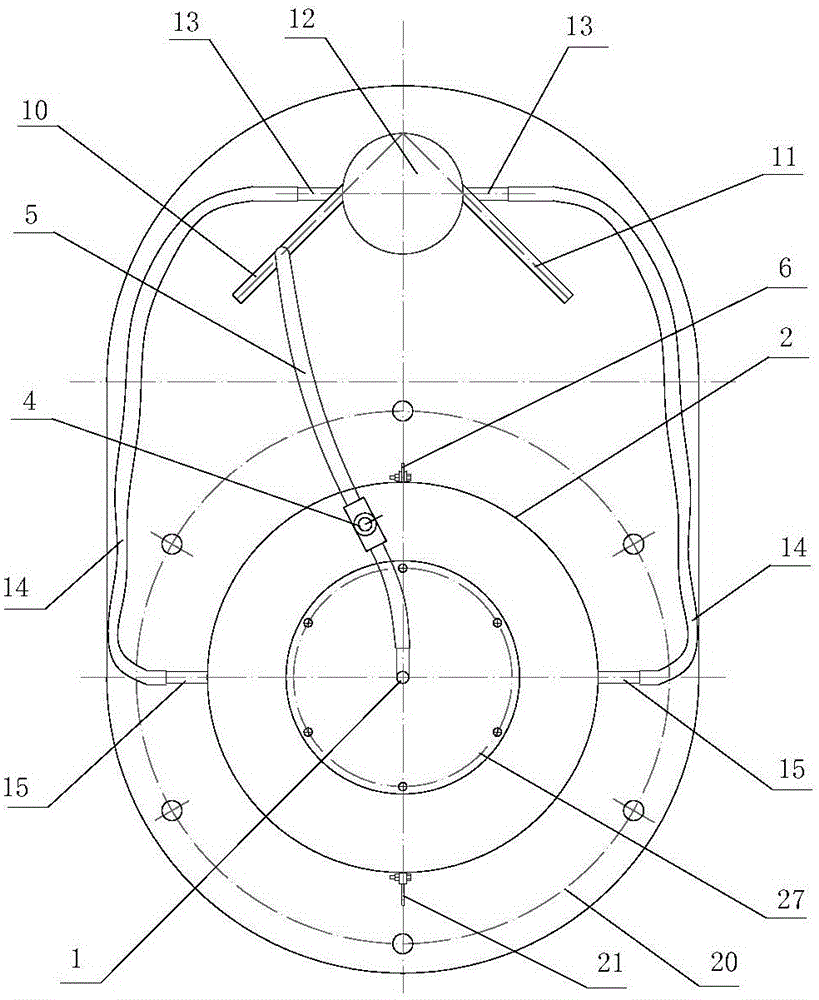

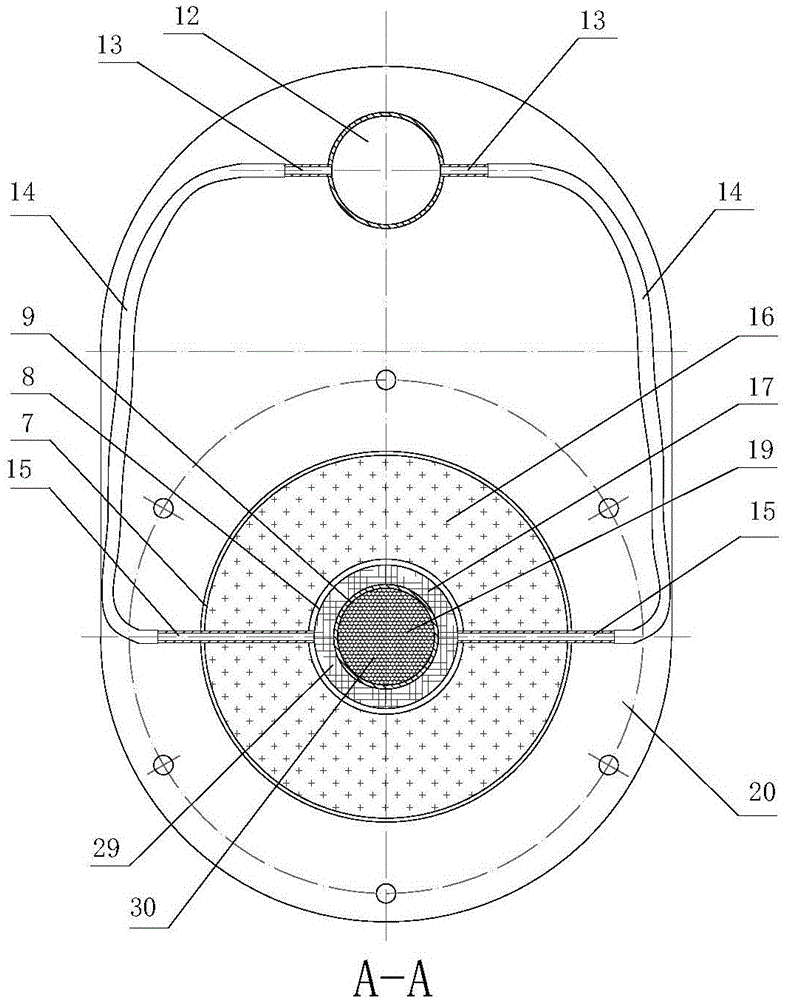

[0029] The ultra-low calorific value gas burner of this embodiment is composed of a premixer, a preheating chamber, a combustion chamber, an igniter and a temperature measuring probe, wherein the premixer 12 used to complete the mixing of ultra-low calorific value gas and air is A cylindrical structure consisting of a closed metal cylinder. One end of the premixer 12 is welded and sealed by a flat plate, and the other end of the premixer 12 is welded on the flange member 20. The air inlet pipe 10 and the gas inlet pipe 11 are symmetrical. Welded at one end of the premixer 12, the air inlet pipe 10 and the gas inlet pipe 11 are symmetrically arranged and form an angle of 90°, and there are two premixed gas outlet pipes corresponding to the other end of the premixing chamber near the flange member 20 13. Premixed gas outlet pipe 13 and premixed gas inlet pipe 15 are connected by premixed gas connecting pipe 14; preheating chamber 29 is surrounded by outer cylinder 8, inner cylind...

Embodiment 2

[0031] The ultra-low calorific value gas burner of this embodiment is composed of a premixer, a preheating chamber, a combustion chamber, an igniter and a temperature measuring probe, wherein the premixer 12 used to complete the mixing of ultra-low calorific value gas and air is A cylindrical structure consisting of a closed metal cylinder. One end of the premixer 12 is welded and sealed by a flat plate, and the other end of the premixer 12 is welded on the flange member 20. The air inlet pipe 10 and the gas inlet pipe 11 are symmetrical. Welded at one end of the premixing chamber, the air inlet pipe 10 and the gas inlet pipe 11 are arranged symmetrically and form an angle of 120°, and there are four premixed gas outlet pipes 13 corresponding to the other end of the premixing chamber near the flange member 20 The premixed gas outlet pipe 13 and the premixed gas inlet pipe 15 are connected by the premixed gas connecting pipe 14; the preheating chamber 29 is surrounded by the out...

Embodiment 3

[0033] The ultra-low calorific value gas burner of this embodiment is composed of a premixer, a preheating chamber, a combustion chamber, an igniter and a temperature measuring probe, wherein the premixer 12 used to complete the mixing of ultra-low calorific value gas and air is A cylindrical structure consisting of a closed metal cylinder. One end of the premixer 12 is welded and sealed by a flat plate, and the other end of the premixer 12 is welded on the flange member 20. The air inlet pipe 10 and the gas inlet pipe 11 are symmetrical. Welded at one end of the premix chamber, and form an included angle of 180°, there are eight premix gas outlet pipes 13 corresponding to the other end of the premix chamber near the flange member 20, the premix gas outlet pipe 13 and the premix gas inlet The air pipes 15 are connected by the premixed gas connecting pipe 14; the preheating chamber 29 is an annular cylindrical space surrounded by the outer cylinder 8, the inner cylinder 9, the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com