A boiler device using cyclone combustion method

A boiler device and cyclone combustion technology, which is applied in the direction of combustion method, fuel burned in molten state, combustion type, etc., can solve the problems of low power generation efficiency, slag hanging, and high pollutant discharge of boilers, and achieve the reduction of high-temperature corrosion and load regulation The effect of large capacity and wide fuel adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

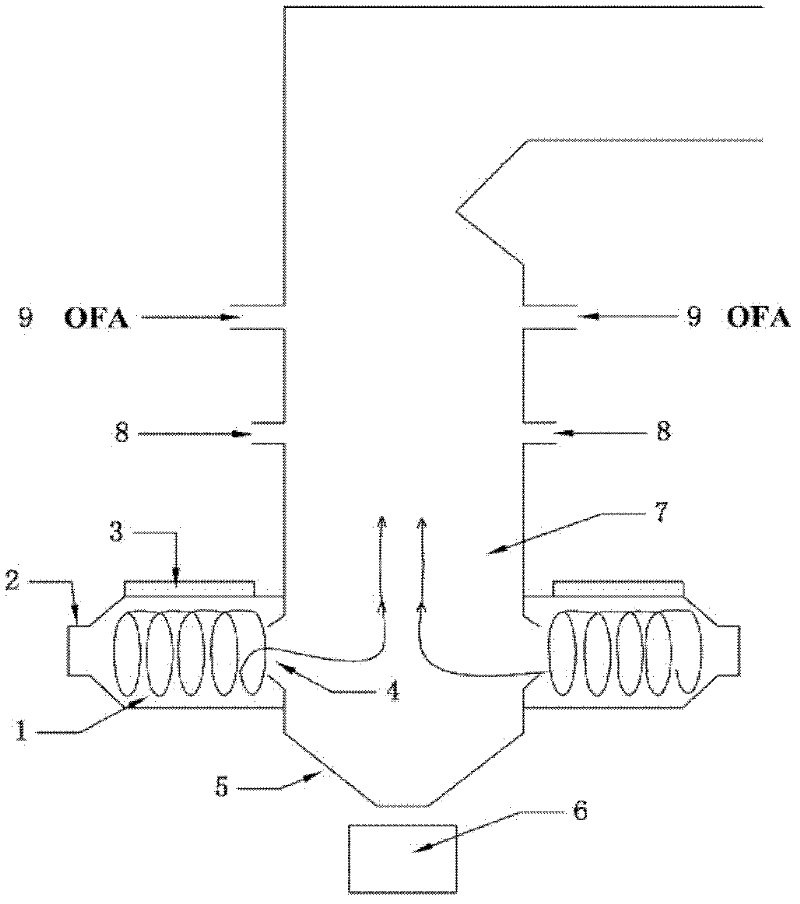

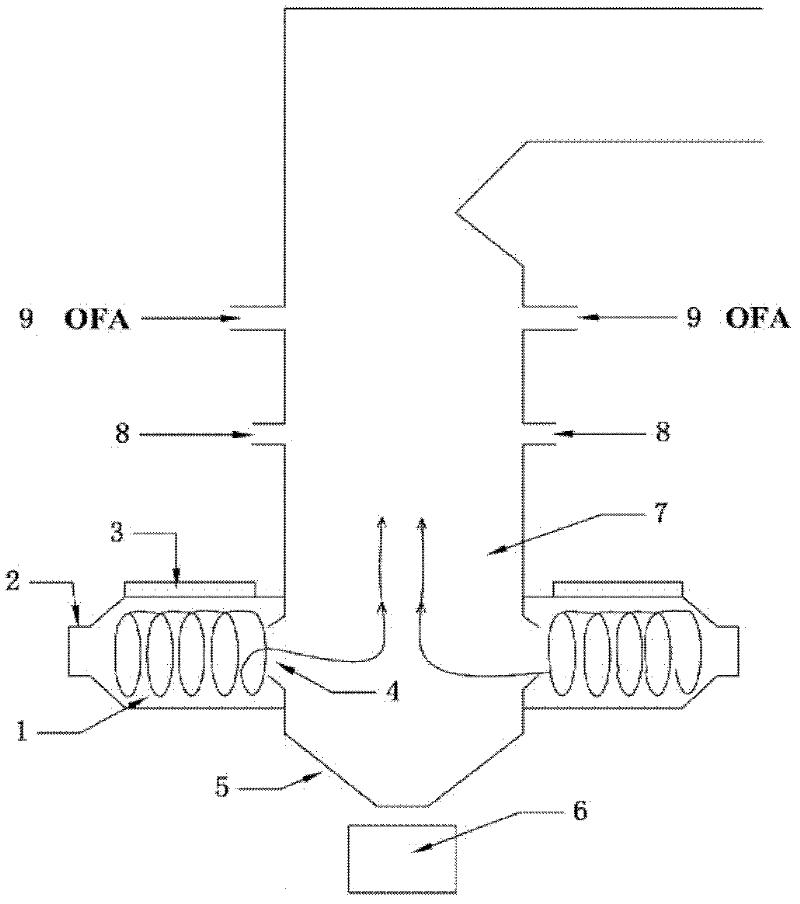

[0044] Such as figure 1 A boiler device using the cyclone combustion method shown mainly includes a cyclone tube 1 , a boiler main furnace 7 and a liquid slag granulation water tank 6 . Among them, the cyclone 1 is a cylindrical structure, and its internal structure is characterized by laying a layer of densely packed pins and a layer of wear-resistant and anti-corrosion lining on the surface of the water-cooled wall. There is a secondary air inlet 3, and its tail is seamlessly connected with the boiler main furnace 7 through a concave outlet 4; the lower tapered part of the boiler main furnace 7 is a cold ash bucket 5, and the lower part of the cold ash bucket 5 is arranged for granulation Granulation water tank 6 for boiler liquid slag discharge.

[0045] In the specific implementation process, the fuel air flow sent into the cyclone from the primary air inlet is strongly mixed with the secondary air sent from the secondary air inlet, and then the excess air coefficient α>1...

Embodiment 2

[0047] Such as figure 1 Shown is a schematic structural diagram of a device for improving the present invention to adopt air staged combustion technology, which mainly includes a cyclone 1 , a boiler main furnace 7 and a liquid slag granulation water tank 6 . Among them, the cyclone 1 is a cylindrical structure, and its internal structure is characterized by laying a layer of densely packed pins on the surface of the water wall and a layer of wear-resistant and anti-corrosion lining. There is a secondary air inlet 3, the tail of which is seamlessly connected with the boiler main furnace 7 through a concave outlet 4; an overfired air (OFA) nozzle 8 is arranged at a certain position on the upper part of the boiler main furnace 7, and the lower tapered part is a cooling The ash hopper 5 and the lower part of the cold ash hopper 5 are arranged with a granulation water tank 6 for granulating the liquid slag discharge of the boiler.

[0048] In the specific implementation process: ...

Embodiment 3

[0050] Such as figure 1 Shown is a schematic structural diagram of a device for improving the present invention to adopt conventional fuel reburning technology, which mainly includes a cyclone 1 , a boiler main furnace 7 and a liquid slag granulation water tank 6 . Among them, the cyclone 1 is a cylindrical structure, and its internal structure is characterized by laying a layer of densely packed pins on the surface of the water wall and a layer of wear-resistant and anti-corrosion lining. There is a secondary air inlet 3, the tail of which is seamlessly connected with the boiler main furnace 7 through a concave outlet 4; a reburning fuel nozzle 8 and an overfired air (OFA) nozzle 9 are respectively arranged at a certain position on the upper part of the boiler main furnace 7, and the lower part The tapering part is the cold ash hopper 5, and the lower part of the cold ash hopper 5 is arranged with a granulation water tank 6 for granulating the liquid slag discharge of the boi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com