Control method of steel ball coal mill material level

The technology of a steel ball coal mill and a control method, which is applied to grain processing and other directions, can solve the problems of low grinding output and high power consumption for pulverizing, and achieve the effects of large grinding output and reducing power consumption for pulverizing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

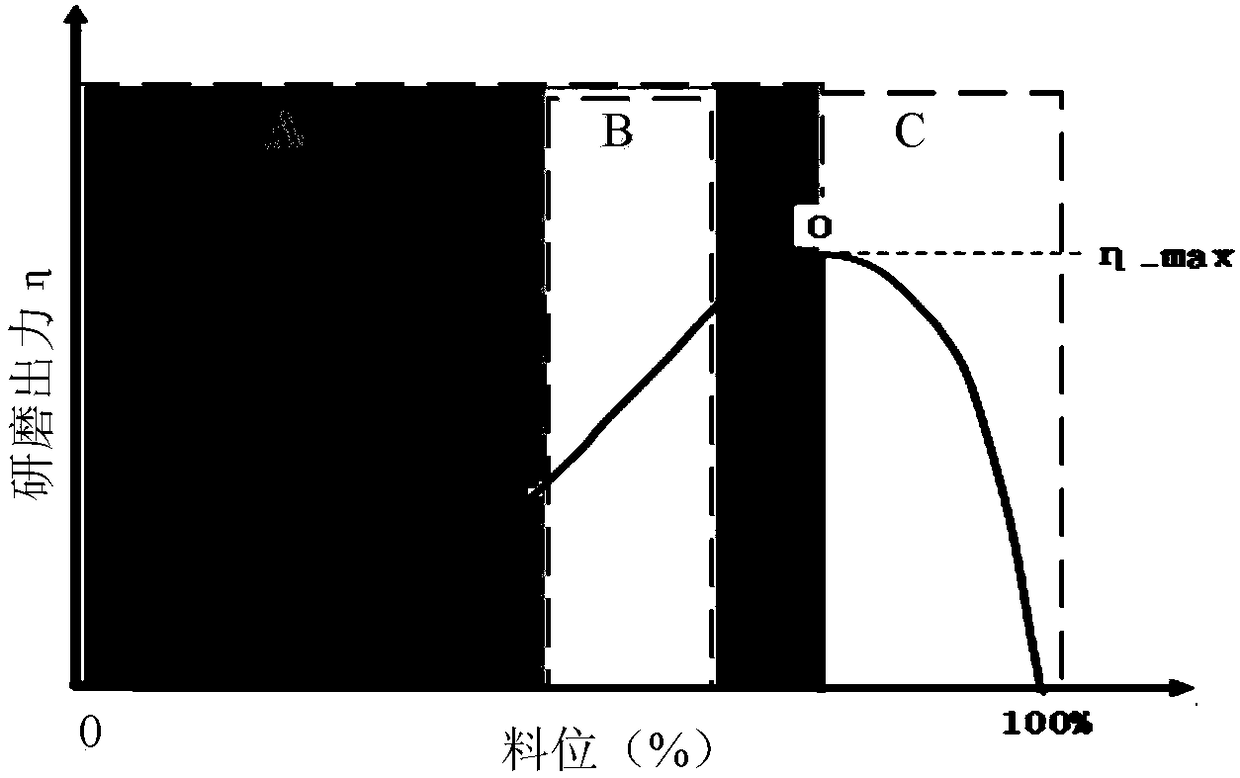

[0042] Specific implementation mode one: combine figure 2 Specifically explain this embodiment, the control method of the material level of the steel ball coal mill described in this embodiment, the method is to use the coal mill current (abbreviated as the mill current) as the controlled quantity, search it online, and find that the grinding output is the largest The current value of the coal mill at that time is used as the given value of the coal mill current. By adjusting the speed of the coal mill or the amount of coal supplied, the current value of the coal mill can track the given value of the coal mill current to realize the steel mill current value. Ball mill material level control.

[0043] The advantage of choosing the mill current as the controlled quantity is: the mill current is only related to the material level of the coal mill, the quality of the steel ball and the coal quality, and is not interfered by factors other than the coal mill. The signal is stable, ...

specific Embodiment approach 2

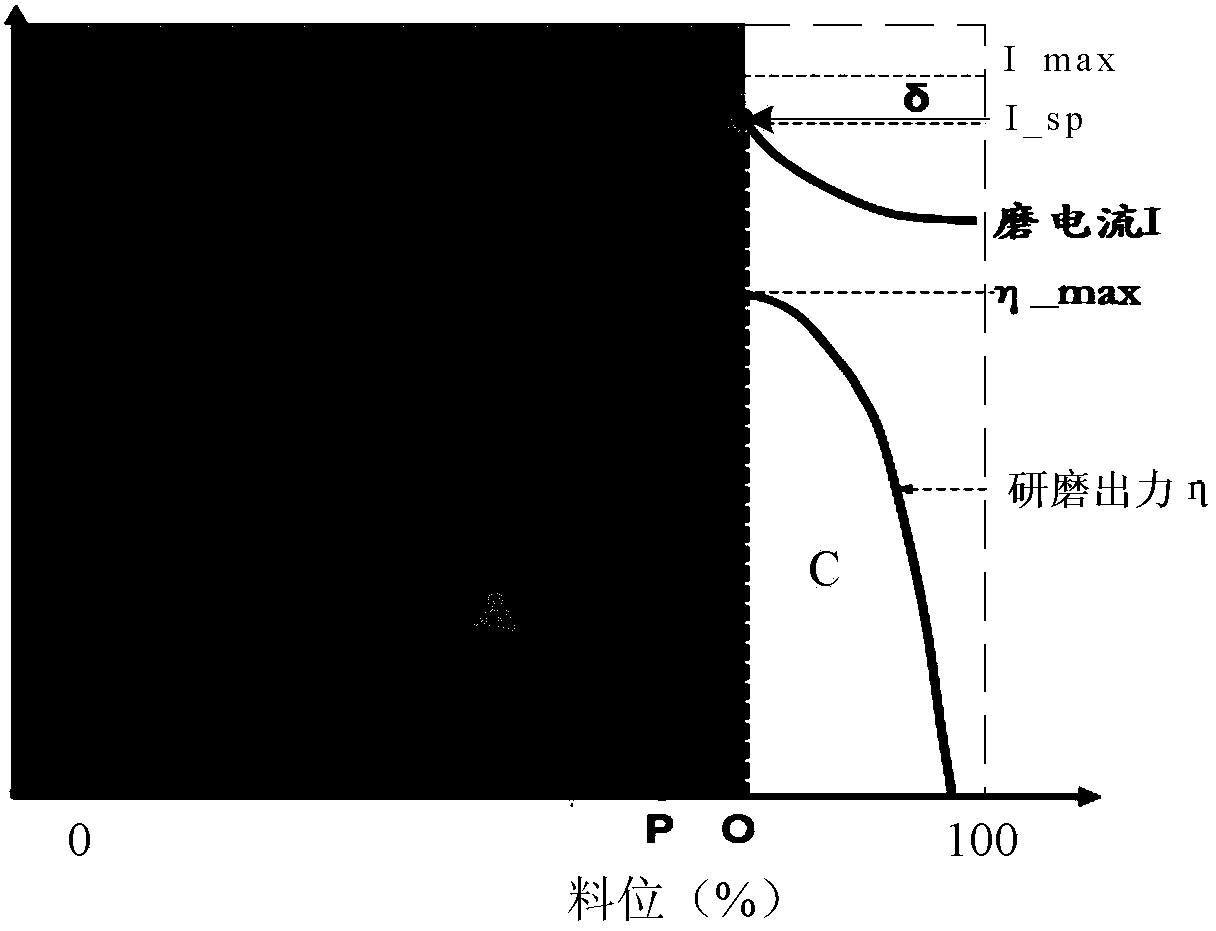

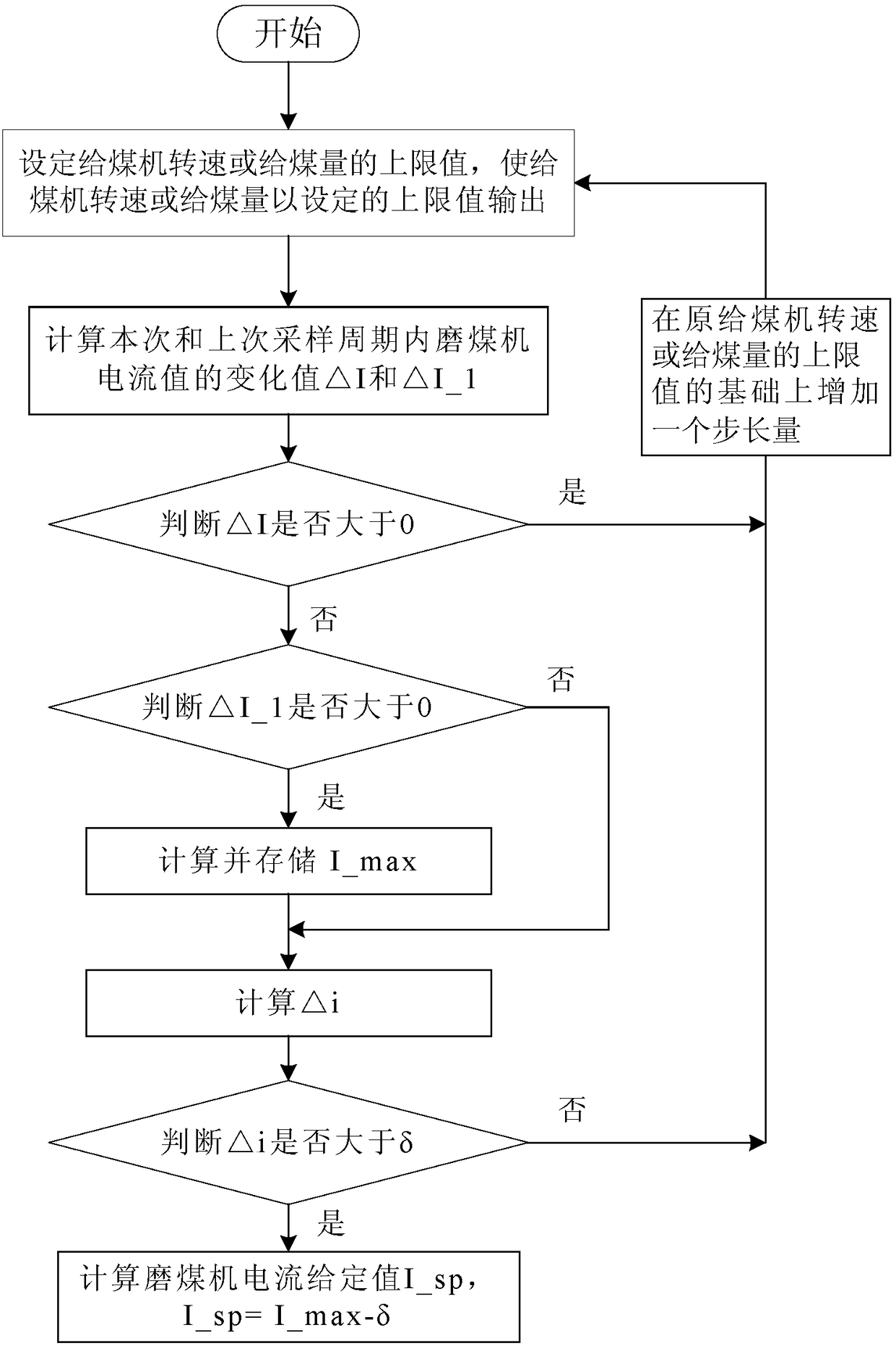

[0046] Specific implementation mode two: combination image 3 Describe this embodiment in detail. This embodiment is a further description of the method for controlling the material level of the steel ball coal mill described in Embodiment 1. In this embodiment, the maximum current of the coal mill is affected by the quality of the steel ball and the quality of the coal. , needs to be searched frequently to obtain the given value of the coal mill current. This search process is also called the mill current optimization process. The optimization process of the given value of grinding current can be divided into manual optimization and automatic optimization. Manual optimization is that the fireman manually adjusts the operation of the pulverizing system, finds and crosses the maximum value of the milling current, and after the δ value drops, manually sets the given value of the milling current, and puts into automatic coal feeding. The automatic optimization is to complete the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com