Integrated pulverized coal separation and concentration device of pulverized-coal boiler

A technology of pulverized coal boiler and coarse powder separator, which is used in solid separation, block/powder supply/distribution, and separation of solids from solids by air flow, which can solve the problem of distinguishing design of concentrators and increasing coal mills. size, low pulverized coal concentration, etc., to achieve the effects of excellent concentration performance, good pulverized coal uniformity, and low power consumption for pulverization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

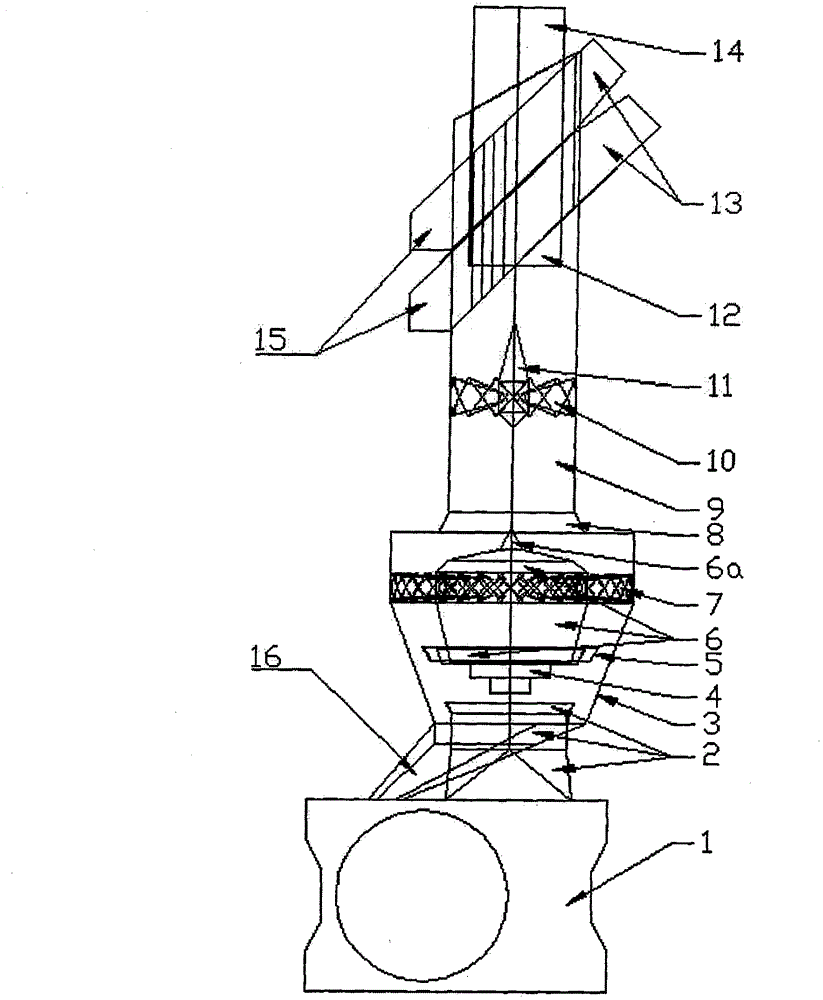

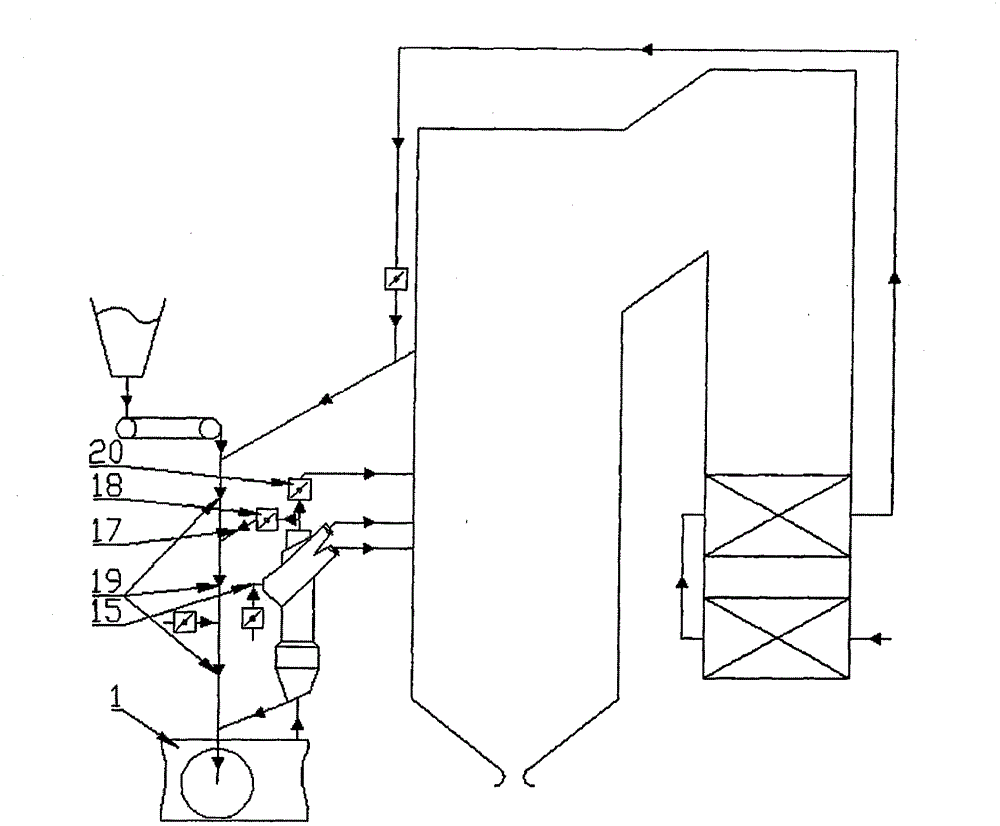

[0013] As shown in the figure, the present invention is a device integrating pulverized coal separation and concentration functions applied to pulverized coal boilers with high-moisture lignite (received base moisture ≥ 40%). It includes an axial type coarse powder separator whose bottom is connected to the coal mill 1 through a powder return pipe 16 and whose top is connected to a tangentially drawn axial type pulverized coal concentrator. The axial type coarse powder separator includes an inlet section 2 connected to the coal mill 1, a closed inner cylinder 6 with a cylindrical step bottom 4 located above the inlet section, and is covered on the upper part of the inlet section 2 and the closed inner cylinder 6 The outer shell 3, the annular guide ring 5 between the closed inner cylinder 6 and the outer shell 3, the angle-adjustable coarse powder separator axial blade 7 installed on the guide ring, the top outlet of the coarse powder separator is a cone Shaped shrinkage 8. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com