Drill grinder

A technology of grinding machine and deceleration mechanism, used in grinding machines, grinding/polishing equipment, metal processing equipment, etc., can solve the problems of unsatisfactory taper surface, waste of steel resources, falling in stone caves, etc., and achieve processing costs. The effect of low power consumption and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing, the present invention will be further elaborated:

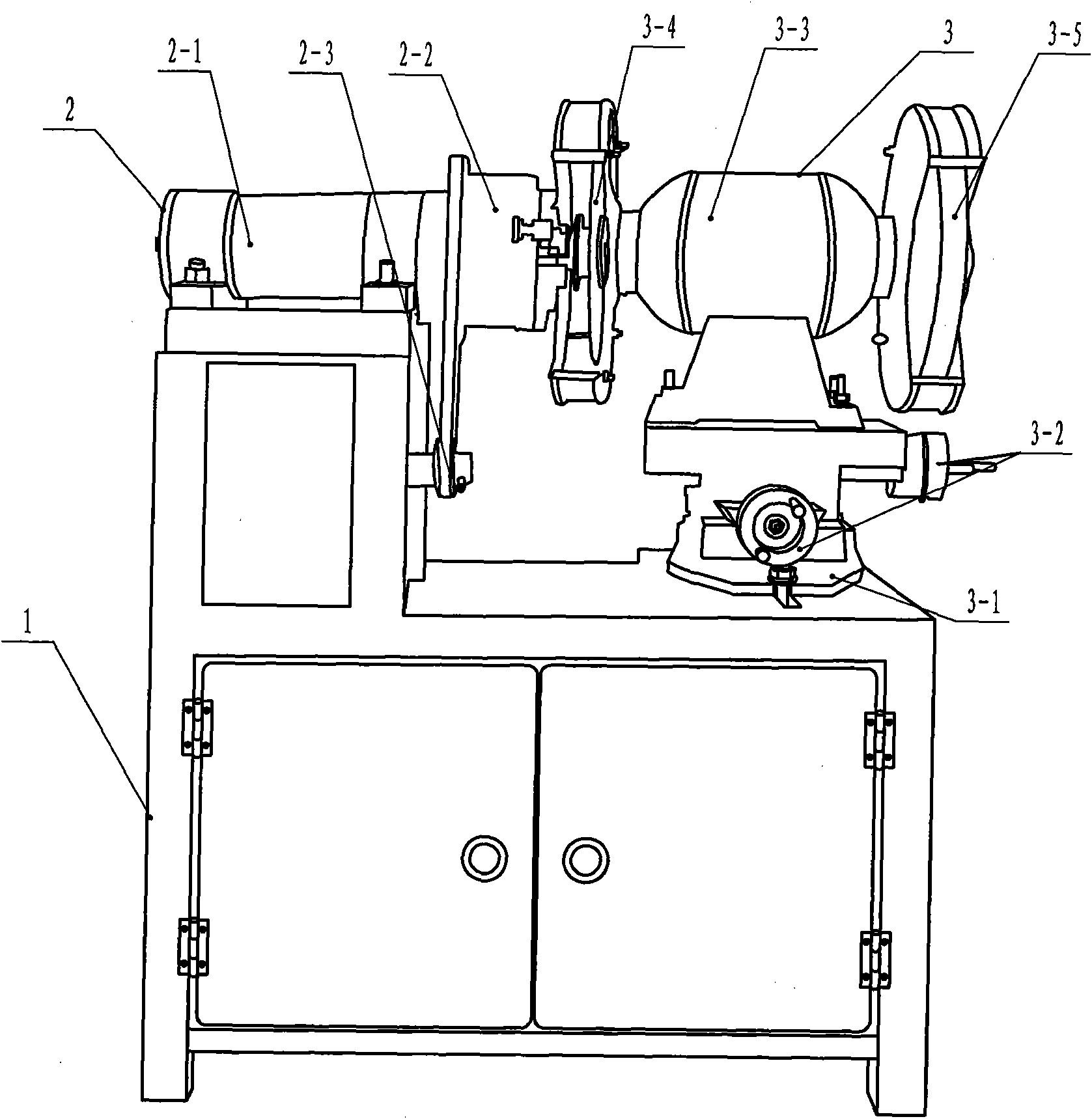

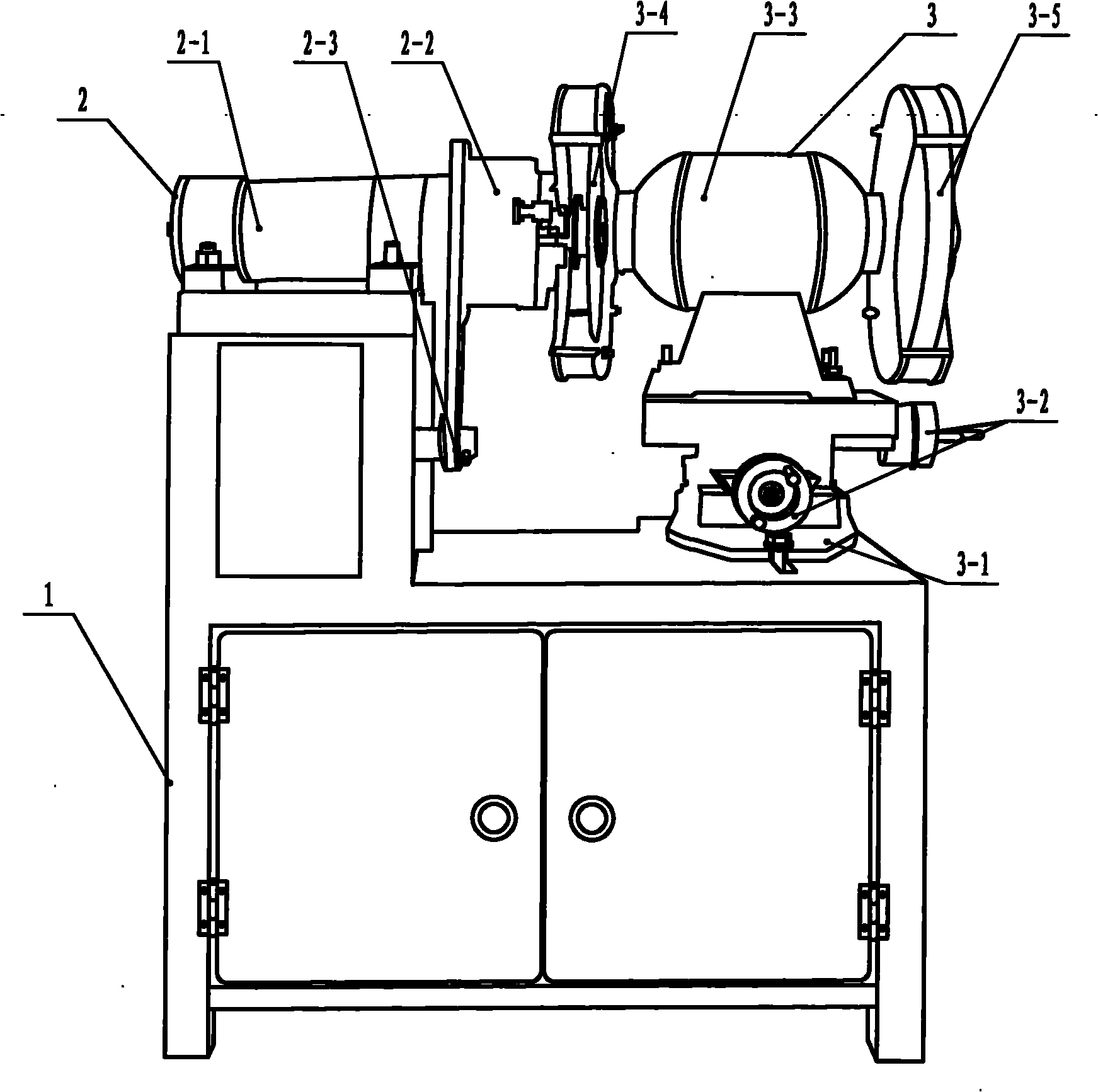

[0019] The brazing machine of the present invention consists of a counter 1, a chuck mechanism 2 fixedly connected to the counter 1 and a rotating cross table 3 opposite to the chuck mechanism 2 on the counter 1.

[0020] The chuck mechanism 2 is composed of the spindle cylinder 2-1, the chuck 2-2 abutted against the spindle cylinder 2-1 and the reduction mechanism 2-3 in the counter 1 connected with the chuck 2-2 and the reduction mechanism 2-3 connected with the reduction mechanism 2-1. 3 connected motors.

[0021] The lower part of the rotary cross table 3 is an angle rotating disk 3-1, the bottom surface of the angle rotating disk 3-1 is fixedly connected with the counter 1, and the X-axis and Y-axis workbenches that can move horizontally and vertically are set on the angle rotating disk 3-1 3-2. A grinder 3-3 is installed on the X-axis and Y-axis table 3-2. The outp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com