Workpiece for thermal error detection, detection method and processing method

A detection method and thermal error technology, applied in metal processing machinery parts, manufacturing tools, metal processing equipment, etc., can solve the problem that the workpiece cannot be reused, and achieve the effect of simple execution, simple operation and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

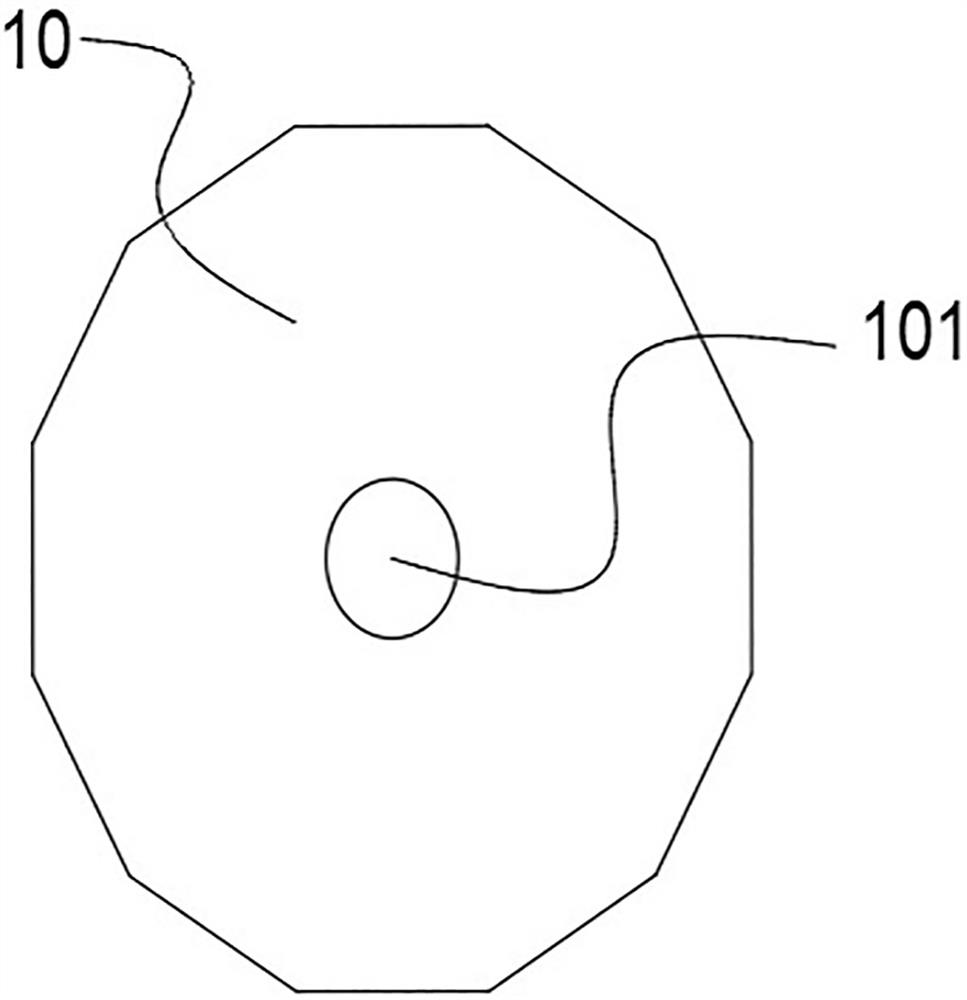

[0037] like figure 1 Shown:

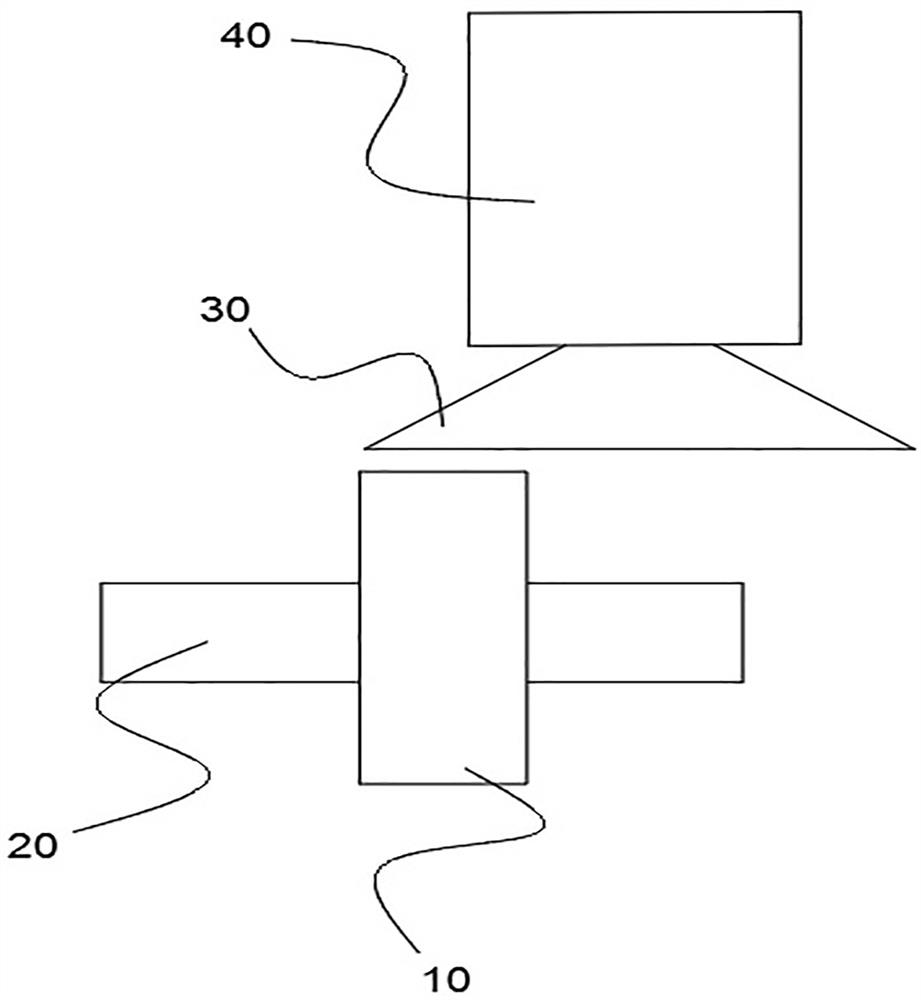

[0038] A workpiece for thermal error detection, comprising a workpiece body 10, the workpiece body 10 includes a prism, the axis of the prism is provided with a central through hole 101 for clamping by a fixture 20, and the prism Color coating on sides.

[0039] Wherein, the prism can be a regular prism, and the central through hole 101 on the axis of the prism can be conveniently clamped and fixed by the clamp 20 of the machine tool; meanwhile, the surface of the workpiece body 10 is coated with a color coating, which is also convenient for observation during processing. of wear and tear.

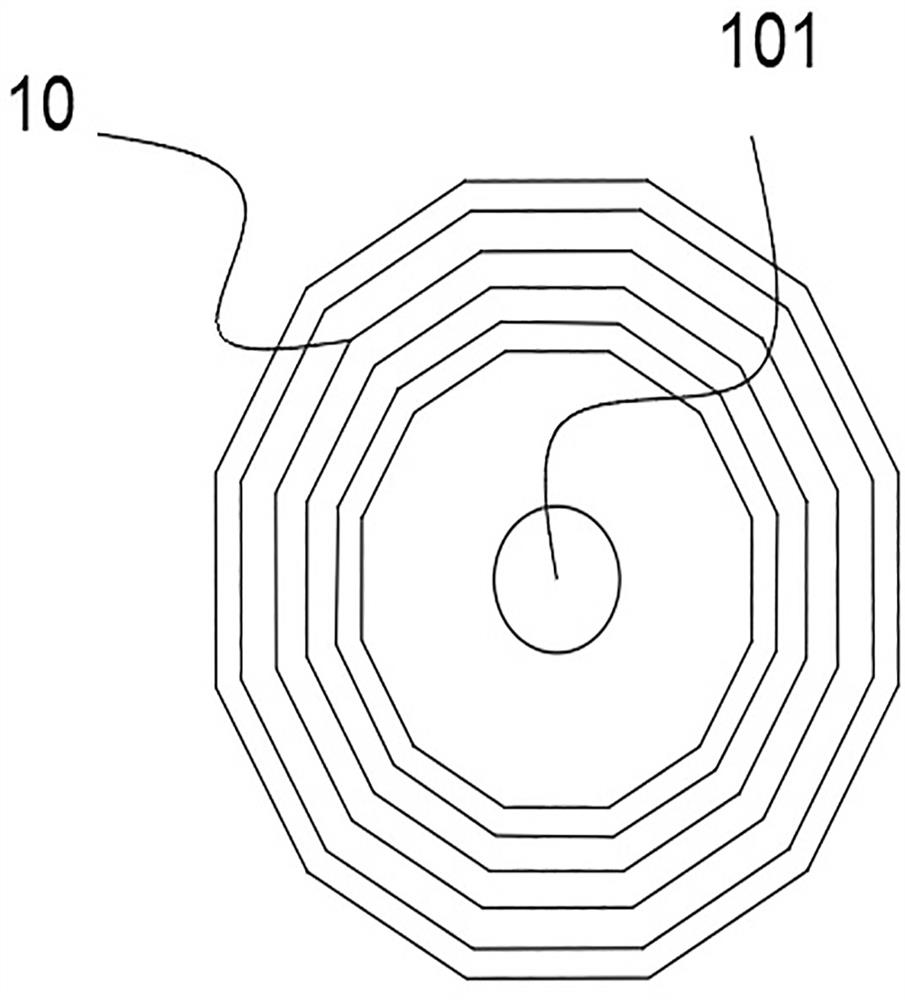

[0040] In another embodiment, such as figure 2 As shown, the workpiece body 10 includes a plurality of prisms with different cross-sectional sizes, the plurality of prisms are connected in sequence in the axial direction, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com