Method for separating components such as iron, zinc and silicon dioxide from lead and zinc smelting water quenching slag

A technology of silica and water-quenched slag, which is applied in the direction of silica, silicon oxide, iron oxide, etc., to achieve the effect of recycling and solving difficult disposal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

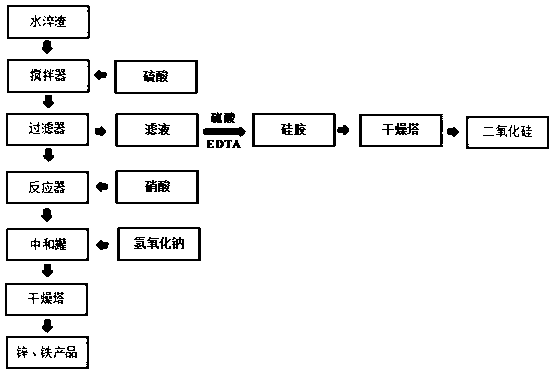

[0016] Below in conjunction with accompanying drawing, the present invention is described in further detail by embodiment:

[0017] The method for separating iron, zinc, silicon dioxide and other components from the water-quenched slag of lead-zinc smelting is characterized in that: it is carried out according to the following steps:

[0018] The water-quenched slag is transported to the batching bin through tools, and then sent to the agitator through the screw scale and conveying machinery, and the sulfuric acid is transported into the agitator at the same time;

[0019] After mixing evenly, measure the acidity of the mixed solution. After reaching the expected acidity, the mixed solution is sent to the filter to separate the filtrate and filter residue; , washed with water, and then the silica gel is transported to a drying tower to obtain silica;

[0020] The filter residue is transported to the reactor, and nitric acid is transported to the reactor at the same time. Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com