Preparation method for super-wetting foam titanium for oil water separation

An oil-water separation, titanium foam technology, applied in separation methods, liquid separation, grease/oily substance/float removal devices, etc., can solve the problems of low liquid penetration rate, low separation efficiency, low mechanical strength, etc., and achieve equipment prices Low cost, high separation efficiency and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

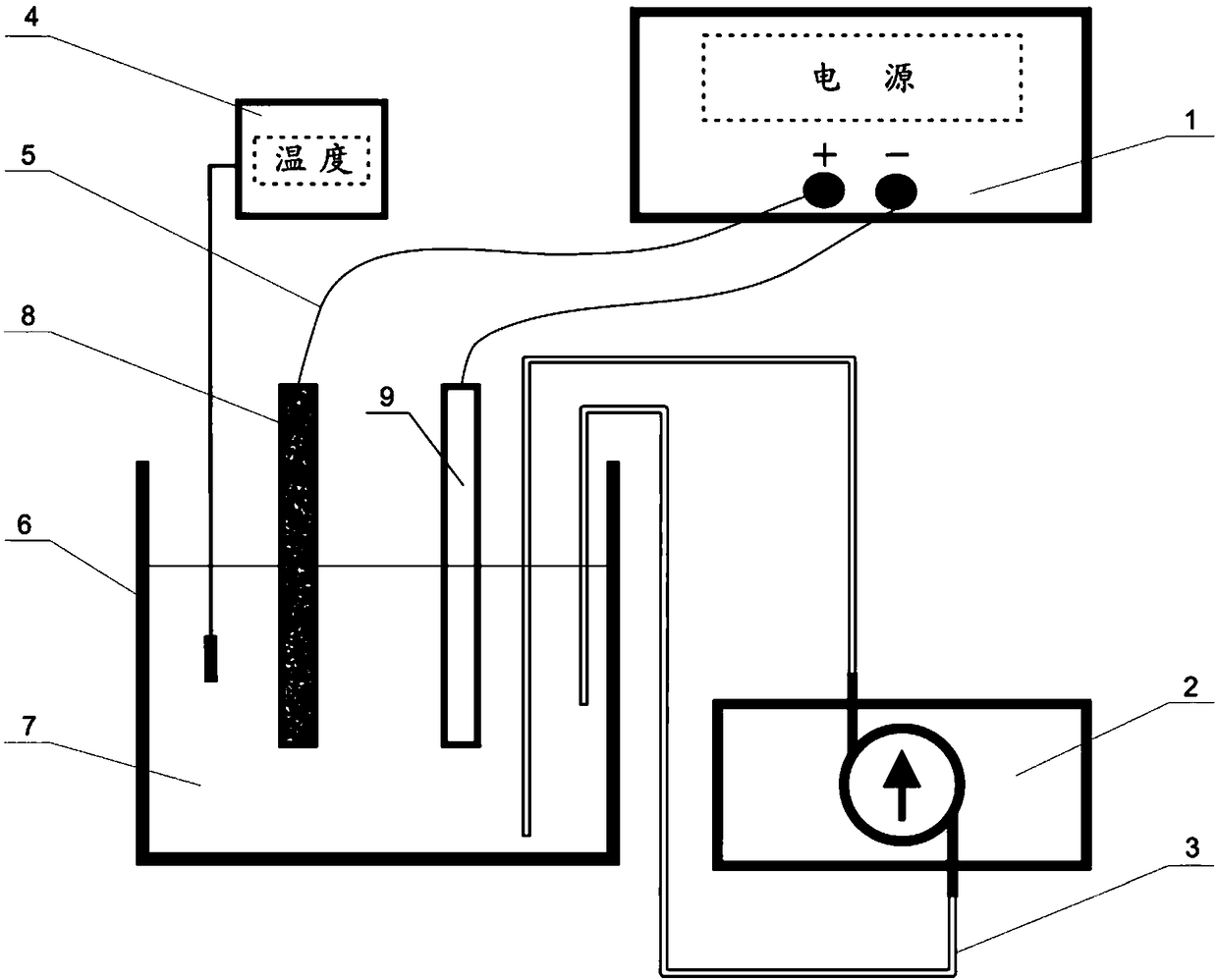

[0038] In this embodiment, the preparation method of super-wetting titanium foam for oil-water separation, the specific steps are as follows:

[0039] (1) Foamed titanium with an area of 1.1cm×0.5cm (filter precision 30μm, thickness 3mm) was sequentially mixed with detergent, deionized water, isopropanol, alcohol, dilute sulfuric acid solution (concentration 0.5mol / L), decontaminated In deionized water, ultrasonic vibration was carried out for 0.5 h respectively.

[0040] (2) The titanium foam after ultrasonic cleaning was repeatedly washed 12 times with deionized water.

[0041] (3) Dry the cleaned titanium foam at 70° C. for 12 hours.

[0042] (4) According to the mass ratio, soak the dried titanium foam in an ethylene glycol solution containing 0.3% ammonium fluoride and 15% water for 40 minutes, so that the inner and outer surfaces of the titanium foam are completely infiltrated by the electrolyte.

[0043] (5) Using foamed titanium as the anode and titanium mesh as th...

Embodiment 2

[0051] The difference from Example 1 is:

[0052] 1, the oil-in-water emulsion adopted in the step (9) is the oil-in-water emulsion of xylene.

[0053] 2. The remaining same steps as in Example 1 were used to prepare super-hydrophilic titanium foam material.

[0054] Under the condition of no external pressure, the separation efficiency of the foamed titanium p-xylene oil-in-water emulsion reaches more than 99.89%.

Embodiment 3

[0056] The difference from Example 1 is:

[0057] 1, the oil-in-water emulsion adopted in the step (9) is the oil-in-water emulsion of octane.

[0058] 2. The remaining same steps as in Example 1 were used to prepare super-hydrophilic titanium foam material.

[0059] Under the condition of no external pressure, the separation efficiency of the titanium foam to the oil-in-water emulsion of octane reaches more than 99.95%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com