Zero-emission treatment process of cutting liquid wastewater

A treatment process and cutting fluid technology, applied in the field of cutting fluid wastewater treatment technology, can solve the problems of membrane flux attenuation, high treatment cost, and inability to fully realize zero discharge of wastewater, and achieve the effect of reducing formation and improving membrane flux.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

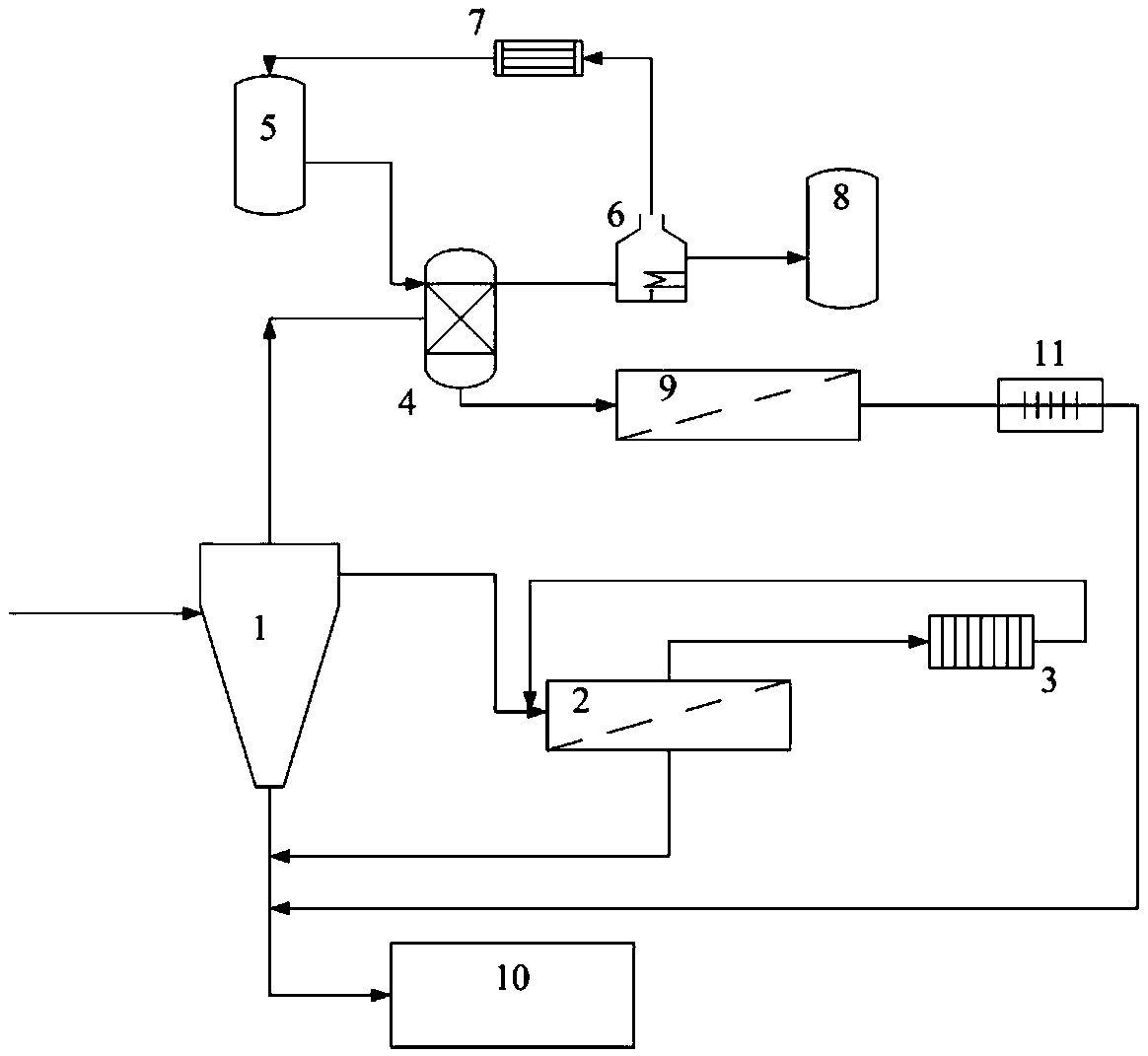

Method used

Image

Examples

Embodiment 1

[0035] The cutting fluid wastewater is sent to the water-oil-solid three-phase cyclone separator for treatment. The pressure difference between the solid phase outlet of the water-oil-solid three-phase cyclone separator and the feed is 0.15MPa, and the oil-water-solid three-phase The output volume ratio is 0.2:3.2:1.1, the feed flow rate is 4m / s, the water phase is sent to the cutting process for reuse; the solid phase outlet of the cyclone separator is sent to the first ceramic membrane for concentration treatment, and the first ceramic membrane The average pore size is 500nm, cross-flow filtration mode is adopted, the membrane surface flow rate is 4m / s, and the operating pressure is 0.3MPa. The concentrated liquid of the first ceramic membrane is sent to the plate and frame filter press to filter out large particles of metal slag, and the plate and frame filter press The filtrate of the machine is returned to the first ceramic membrane to be filtered again, and the filtrate o...

Embodiment 2

[0038] The cutting fluid wastewater is sent to the water-oil-solid three-phase cyclone separator for treatment. The pressure difference between the solid phase outlet of the water-oil-solid three-phase cyclone separator and the feed is 0.35MPa, and the oil-water-solid three-phase The output volume ratio is 0.25: 4.2: 1.4, the feed flow rate is 6m / s, the water phase is sent to the cutting process for reuse; the solid phase outlet of the cyclone separator is sent to the first ceramic membrane for concentration treatment, and the first ceramic membrane The average pore size is 500nm, cross-flow filtration mode is adopted, the membrane surface flow rate is 4m / s, and the operating pressure is 0.2MPa. The filtrate of the machine is returned to the first ceramic membrane to be filtered again, and the filtrate of the first ceramic membrane is sent to the cutting process for reuse;

[0039] Step 3, the oil phase in step 1 is mixed with the extractant, the extractant is mixed with KOH a...

Embodiment 3

[0041] The cutting fluid wastewater is sent to the water-oil-solid three-phase cyclone separator for treatment. The pressure difference between the solid phase outlet of the water-oil-solid three-phase cyclone separator and the feed is 0.2MPa, and the oil-water-solid three-phase The output volume ratio is 0.2:3.8:1.2, the feed flow rate is 5m / s, the water phase is sent to the cutting process for reuse; the solid phase outlet of the cyclone separator is sent to the first ceramic membrane for concentration treatment, and the first ceramic membrane The average pore size is 500nm, cross-flow filtration mode is adopted, the membrane surface flow rate is 3m / s, and the operating pressure is 0.4MPa. The filtrate of the machine is returned to the first ceramic membrane to be filtered again, and the filtrate of the first ceramic membrane is sent to the cutting process for reuse;

[0042] Step 3, the oil phase in step 1 is mixed with the extractant, the extractant is mixed with KOH and n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com