Regenerative braking energy recovery system of hydraulically-driven automobile

A technology of regenerative braking and energy recovery, which is applied in the direction of brakes, braking components, braking transmission devices, etc., can solve the problems of limited remaining space and difficulties, and achieve the effects of reduced transmission structure, low cost and good passability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

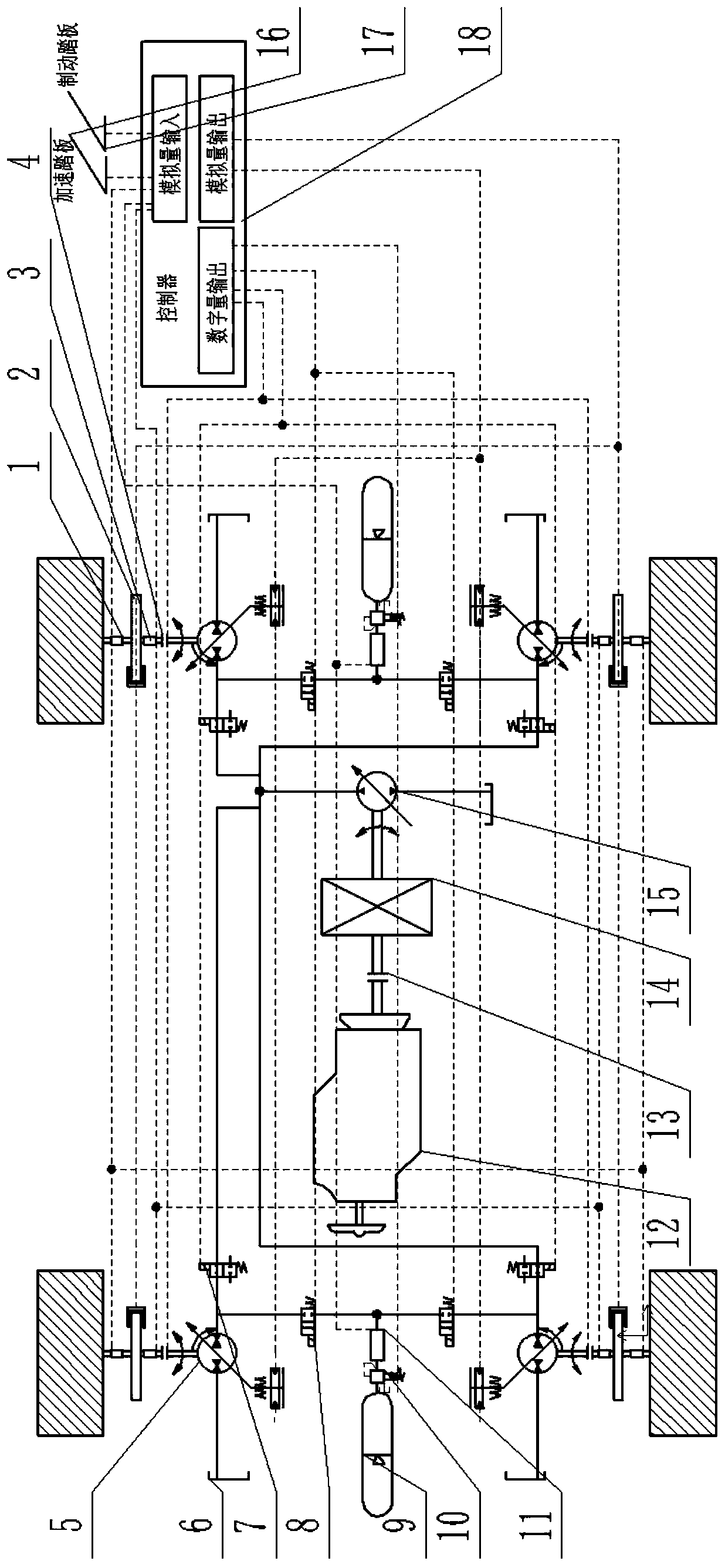

[0015] Further illustrate the present invention below in conjunction with accompanying drawing

[0016] Refer to the accompanying drawings in the manual:

[0017] The hydraulic drive and regenerative braking energy recovery system includes: a speed sensor 1, a friction brake 2, a torque sensor 3, an electromagnetic clutch 4, a secondary element pump / motor 5, a hydraulic cylinder 6, a first two-position two-way electromagnetic Reversing valve 7, second two-position two-way electromagnetic reversing valve 8, high pressure accumulator 9, pilot pressure control valve 10, pressure sensor 11, engine 12, clutch 13, reduction box 14, hydraulic master cylinder 15, accelerator pedal 16, brake pedal 17, controller 18.

[0018] When the car is driving normally, the hydraulic braking energy recovery system does not participate in the work, at this time the second two-position two-way electromagnetic reversing valve 8 is in the normally open state, and the first two-position two-way electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com