Drying, dehydrating and dehumidifying device

A drying and cabinet technology, applied in the direction of drying gas arrangement, local stirring dryer, static material dryer, etc., can solve the problems of environmental pollution, waste of heat energy, limit the temperature and air volume of recovered waste heat, and reduce environmental pollution. , to achieve the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

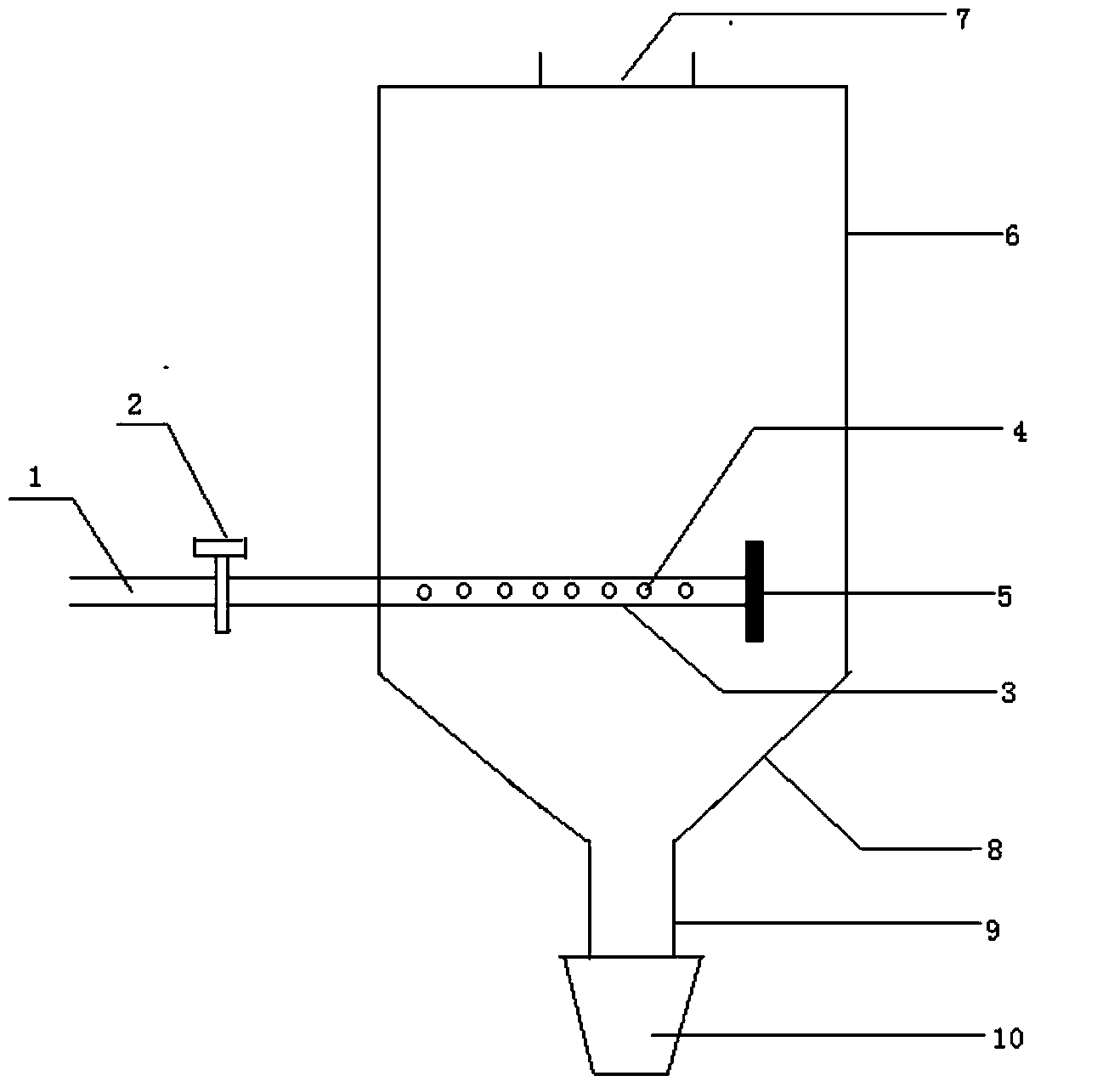

[0014] A dry dehydration and dehumidification device is composed of an air inlet pipe 1, an air regulating valve 2, a dehydration and dehumidification pipe 3, and a box body 6. The dehydration and dehumidification pipe 3 is connected with the air inlet pipe 1 through the air regulating valve 2, and the other end of the dehydration and dehumidification pipe 3 There is a blind plate 5, the surface of the dehydration and dehumidification pipe 3 is evenly covered with holes 4, the diameter of the hole 4 is 3mm, the top of the box body 6 has a feed port 7, and the bottom has a hopper 8, and the end of the hopper 8 is a discharge port 9. The feeding port 9 is provided with a screw pusher 10 .

Embodiment 2

[0016] Same as embodiment 1, the difference is that the diameter of the hole 4 is 4mm, and the discharger 10 is a common discharger.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com