Ballast water bactericide and preparation method thereof

A technology of ballast water and fungicides, applied in botany equipment and methods, biocides, disinfectants, etc., can solve problems such as increased costs, operational complexity, failure to meet standards, etc., to promote a virtuous circle and enhance synergy effect, the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

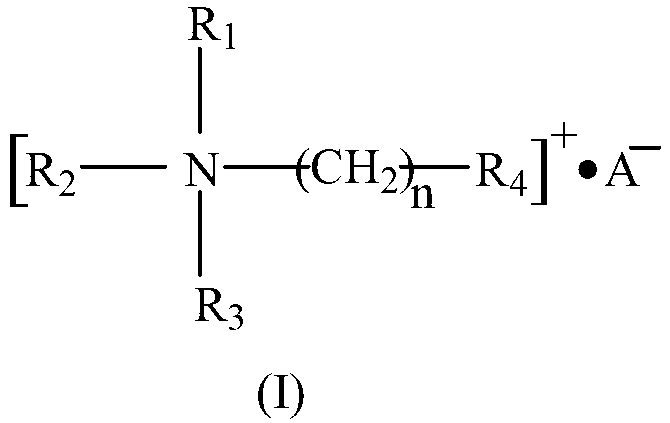

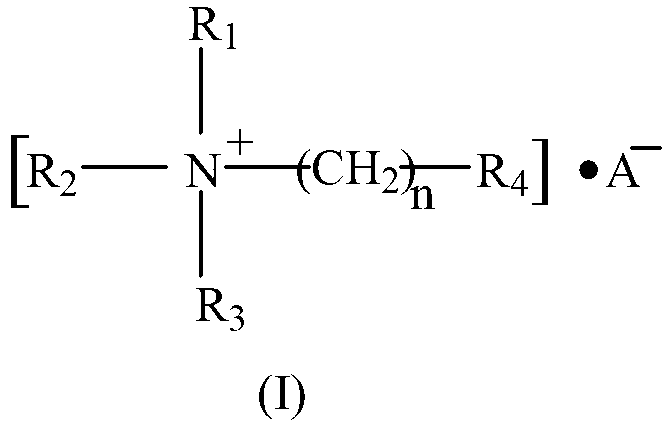

Method used

Image

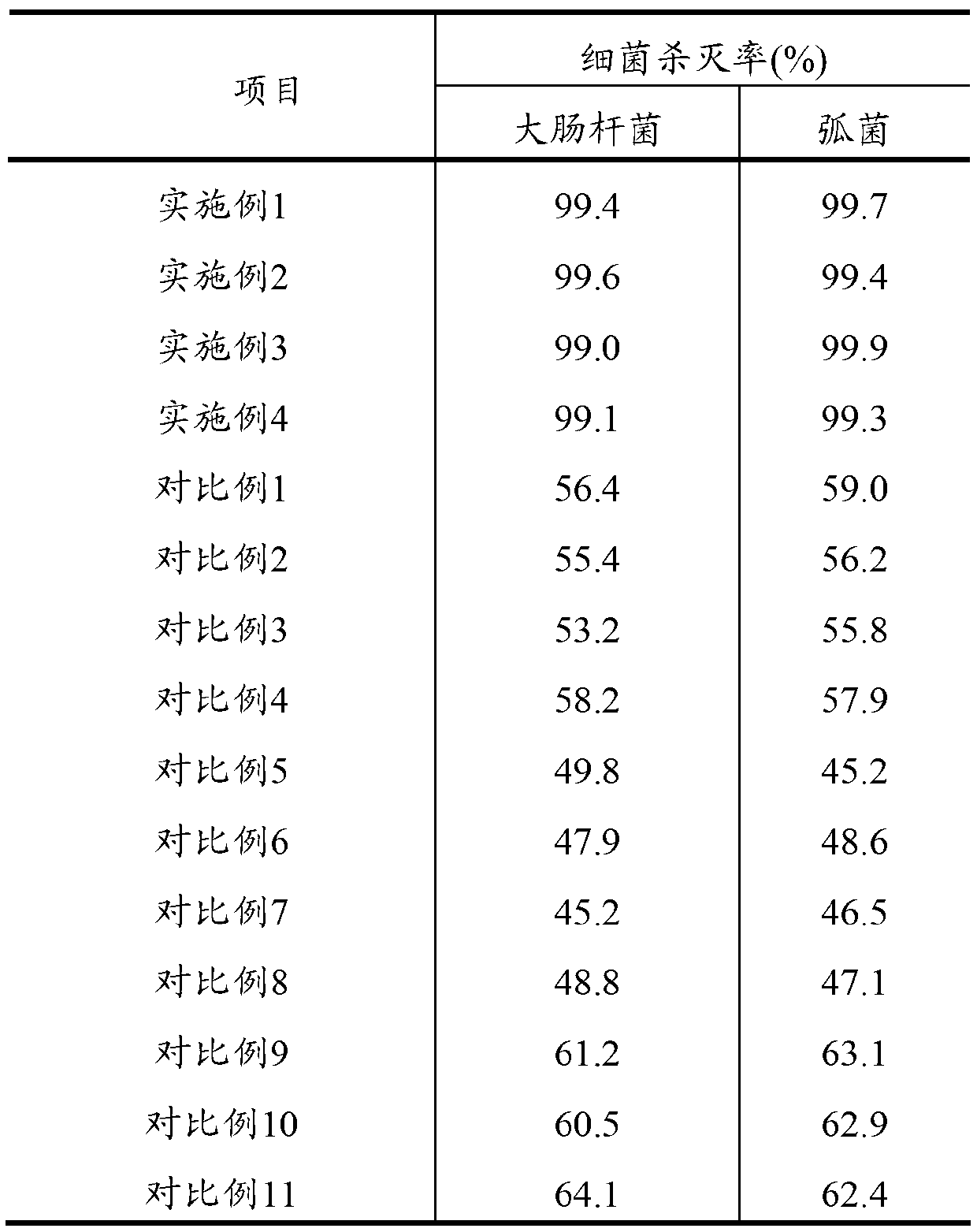

Examples

Embodiment 1

[0047] The shells of the mussels were soaked in an aqueous NaOH solution with a concentration of 1% by mass for 0.5 hours, and then soaked in an aqueous solution of HCl with a concentration of 5% by mass for 0.5 hours. After soaking, rinse with distilled water, dry, and then grind to a particle size of 150 μm with a roller mill.

[0048] Calcining and activating the shell powder obtained above at 800°C for 1 hour, adding 0.5% by mass of sodium stearate and mixing, stirring evenly, drying, and then sieving to obtain an active shell skeleton material with a particle size of 150 μm.

[0049] The active shell skeleton material and dodecyl dimethyl benzyl ammonium chloride are fully and uniformly mixed in a mass ratio of 7:2 to obtain the powdered ballast water fungicide of the present invention.

Embodiment 2

[0051] Soak the shells of pearl oyster and meretrix meretrix with a mass percentage concentration of 2% for 1 hour with a mass ratio of 1:1, and then use a mass percentage concentration of 5% H 2 SO 4 Soak in water solution for 1 hour. After soaking, rinse with distilled water, dry, and then grind to a particle size of 160 μm with a roller mill.

[0052] Calcinate and activate the shell powder obtained above at 900°C for 1.5 hours, add 1% of its mass of sodium dodecylbenzenesulfonate and mix, stir evenly, dry, and then sieve to obtain active shells with a particle size of 160 μm Skeleton material.

[0053] The active shell skeleton material and octyldiethylbenzylammonium sulfite are fully and uniformly mixed in a mass ratio of 8:2 to obtain the powdered ballast water fungicide of the present invention.

Embodiment 3

[0055] The shells of the clams were soaked in 2% NaOH aqueous solution for 0.7 hours, and then soaked in 5% HCl aqueous solution for 0.8 hours. After soaking, rinse with distilled water, dry, and then grind to a particle size of 170 μm with a roller mill.

[0056] Calcinate and activate the above-mentioned shell powder at 1000°C for 2 hours, add 2.5% of its mass of sodium lauryl alcohol ether sulfate and mix, stir evenly, dry, and then sieve to obtain active shells with a particle size of 170 μm Skeleton material.

[0057] The active shell skeleton material and pentadecyldipropylphenylpropylammonium bromide are fully and uniformly mixed in a mass ratio of 7:3 to obtain the powdered ballast water fungicide of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com