Processing technology of waste oil-based mud and oil-based drilling cuttings

A technology of oil-based mud and oil-based drilling cuttings, which is applied in the fields of earth-moving drilling, wellbore/well components, etc., can solve the problems of pollution of oil-based mud and oil-based drilling cuttings, and achieves no secondary pollution, equipment investment and The effect of low operating cost and convenient discharge treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

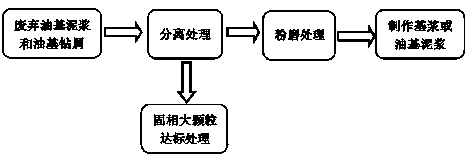

Method used

Image

Examples

Embodiment 1

[0013] The waste oil-based mud and oil-based drilling cuttings collected in the drilling production of an oilfield are ground according to the requirements through the corresponding grinding process. The waste oil-based mud and oil-based drilling After being ground, the index of the shavings meets the requirement of being remade into base slurry or oil-based mud, and can be directly added into the production process as a raw material. Its technology realizes the recycling and harmless treatment of oil-based mud and oil-based drilling cuttings, and can recover most of the waste oil-based mud. There is no secondary pollution, low equipment investment and operating costs, and significant environmental, social and economic benefits.

[0014] Example: Economic benefit analysis of 1 ton waste oil-based mud and oil-based drilling cuttings treatment

[0015] Assume that the treatment service fee is 1,000 yuan (income); 1 ton of waste oil-based mud and oil-based drilling cuttings has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com