Integral leaching detoxication and landfill treatment method of chromium slag

A treatment method, chromium slag technology, applied in the direction of solid waste removal, etc., can solve the problems of slow progress, unsatisfactory treatment effect, high treatment cost, etc., and achieve the effect of eliminating environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] specific implementation

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

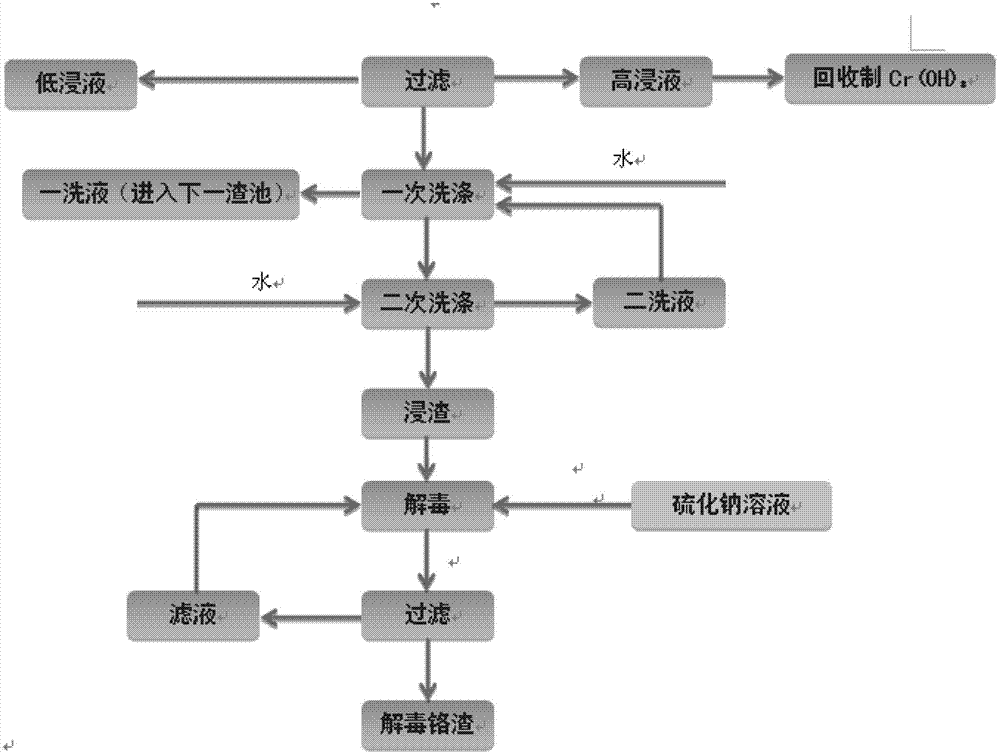

[0027] Such as figure 1 As shown, the present invention provides a kind of chromium slag leaching detoxification and landfill integrated processing method, wherein, comprises the following steps:

[0028] 1) Construct a detoxification pool on the ground: excavate a landfill pool of a corresponding size on the ground according to the amount of chromium slag to be treated, set an anti-seepage layer on the wall of the landfill pool, and set an outward diversion tank in the landfill pool diversion system;

[0029] 2) Transporting the chromium slag to be treated to the detoxification pool, and adding water to the detoxification pool, the chromium slag leaches hexavalent chromium and / or combines hexavalent chromium in the water, and the water added at this time becomes the leachate;

[0030] 3) Recover the leaching solution through the div...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com