Spraying device for surface treatment of air reactor

A technology of air-core reactor and surface treatment, applied in the direction of spraying device, liquid spraying device, etc., can solve the problems of vertical placement, difficult operation, waste of paint, etc., achieve good spraying effect, realize rotary spraying, and realize recycling The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

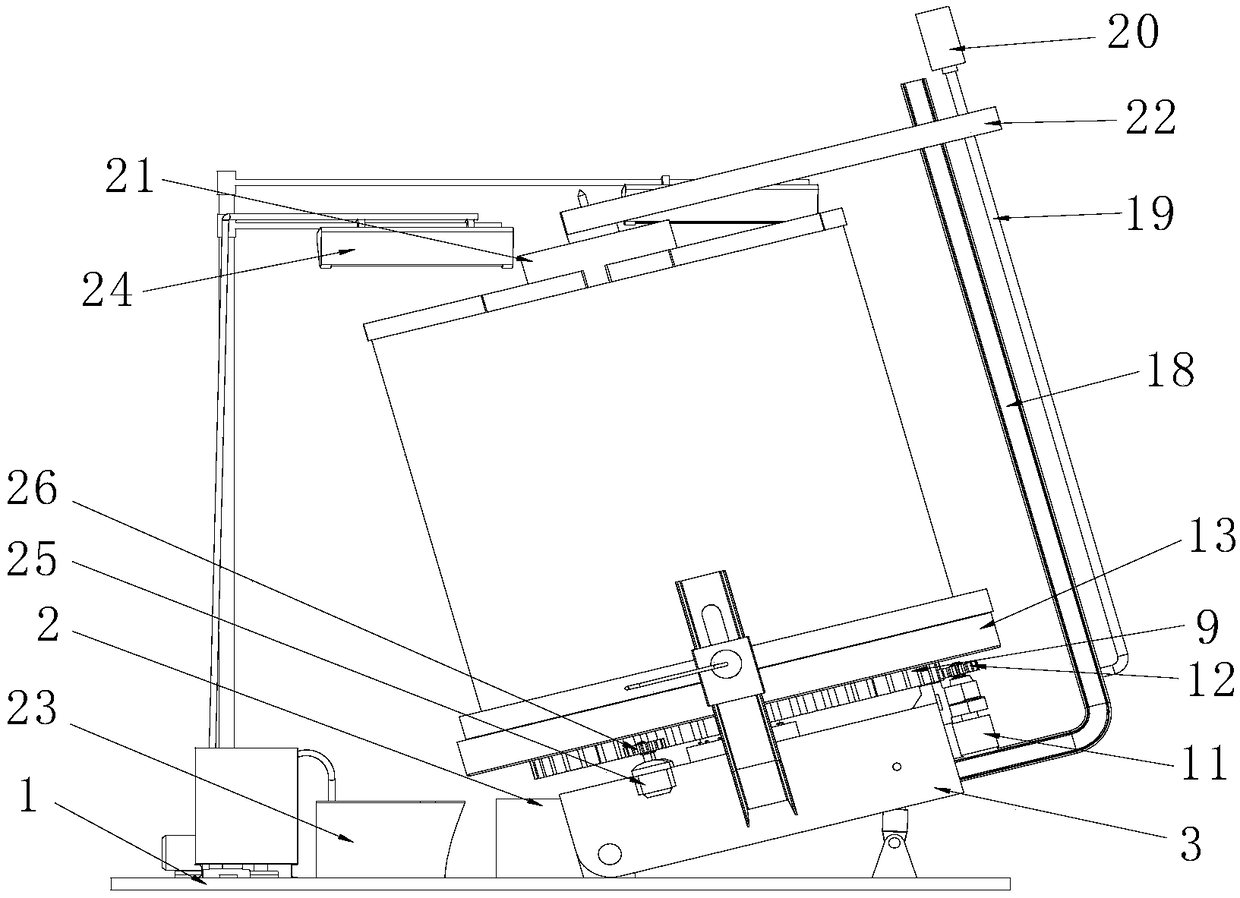

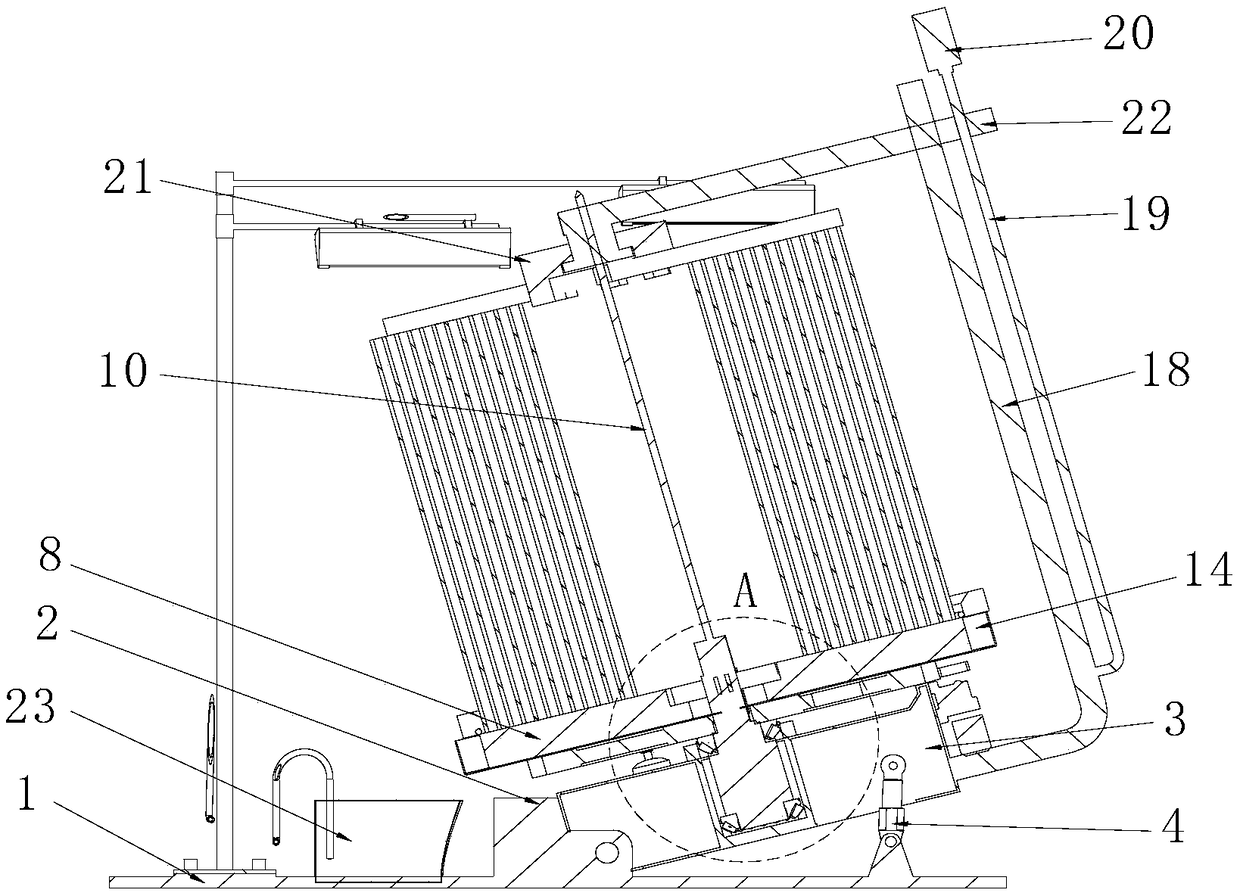

[0026] Such as Figure 1-7 The spraying device shown is used for the surface treatment of large-scale air-core reactors (hereinafter referred to as workpieces), and it includes two parts: a clamping assembly and a spraying assembly, both of which are set on the device base 1 located on the ground superior.

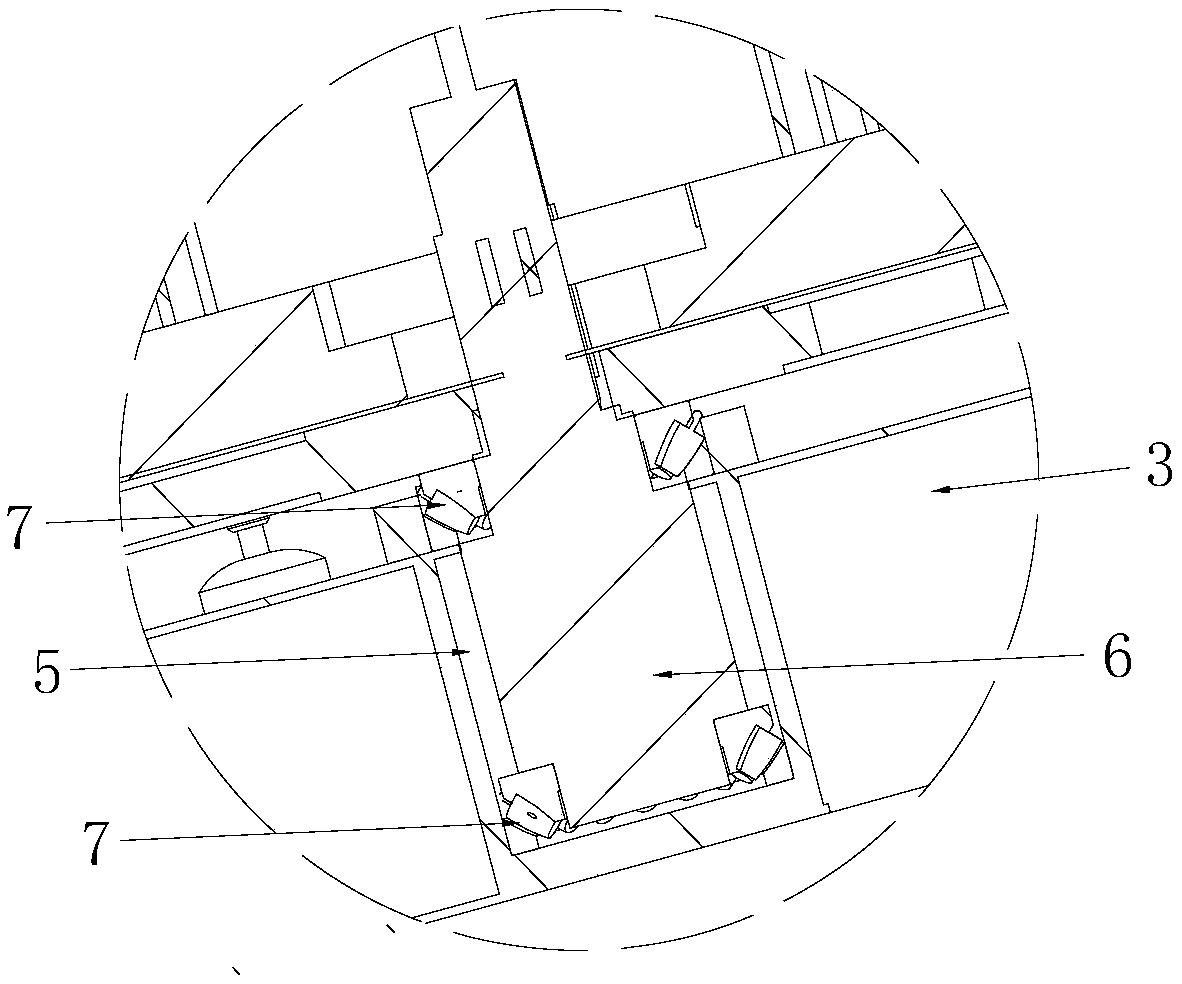

[0027] In this embodiment, the clamping assembly includes a limit seat 2 fixed on the device base 1, the position limit seat 2 is extended at the position connected to the device base 1 to form a transfer portion, and the support base 3 is rotatably connected to the The axis of rotation on the transfer portion and supporting the base 3 is parallel to the device base 1 . The device base 1 is also hinged with a tilting hydraulic cylinder 4 as a power assembly, the piston rod of the tilting hydraulic cylinder 4 is hinged with the support base 3, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com