A kind of LED product spraying equipment

A technology of spraying equipment and products, which is applied in the direction of spraying devices, etc., which can solve the problems of inconvenient rotating spraying of LED products, cumbersome placement of LED products, inconvenience of collecting LED products, etc., to improve the spraying range, improve spraying efficiency and spraying effect, and facilitate movement and the effect of installing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

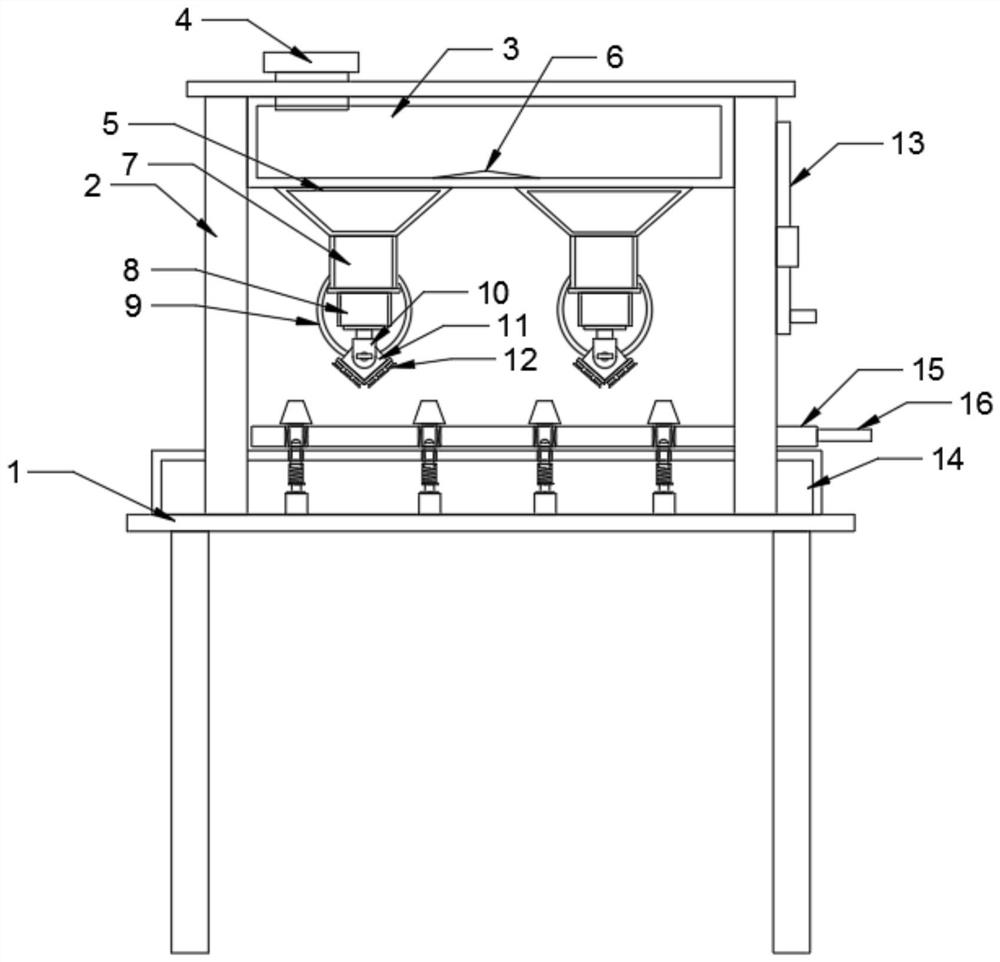

[0023] see Figure 1~4 , in an embodiment of the present invention, a LED product spraying equipment includes a workbench 1, a spray head 12 and a support plate 15, a fixing frame 2 is installed on the upper end of the workbench 1, and a liquid storage tank 3 is installed on the inner top of the fixing frame 2, The left side of the top of the liquid storage tank 3 is provided with a liquid injection port 4, the inner bottom of the liquid storage tank 3 is provided with a deflector 6 in the middle, the left and right sides of the bottom of the liquid storage tank 3 are provided with a funnel 5, and the inner side of the funnel 5 is provided with a filter. , the sectional shape of deflector 6 is an isosceles triangle, and two groups of funnels 5 are symmetrical about the middle part of liquid storage tank 3; A turret 10 is installed, a spraying frame 11 is installed on the inside of the turret 10, and a sprinkler 12 is installed on the side of the spraying frame 11. The shape of...

Embodiment 2

[0027] see Figure 5 , in an embodiment of the present invention, a LED product spraying equipment includes a workbench 1, a spray head 12 and a support plate 15, a fixing frame 2 is installed on the upper end of the workbench 1, and a liquid storage tank 3 is installed on the inner top of the fixing frame 2, The left side of the top of the liquid storage tank 3 is provided with a liquid injection port 4, the middle part of the inner bottom of the liquid storage tank 3 is provided with a deflector 6, the left and right sides of the bottom of the liquid storage tank 3 are provided with funnels 5, and the bottom of the funnel 5 is equipped with a fixed Box 7, telescopic motor 8 is installed on fixed box 7 bottoms, telescopic motor 8 front ends are equipped with turret 10, and spray frame 11 is installed on the inboard of turret 10, spray nozzle 12 is installed on spray frame 11 side, fixed box 7 left and right sides are provided with Rubber hose 9 is arranged, and the bottom end...

Embodiment 3

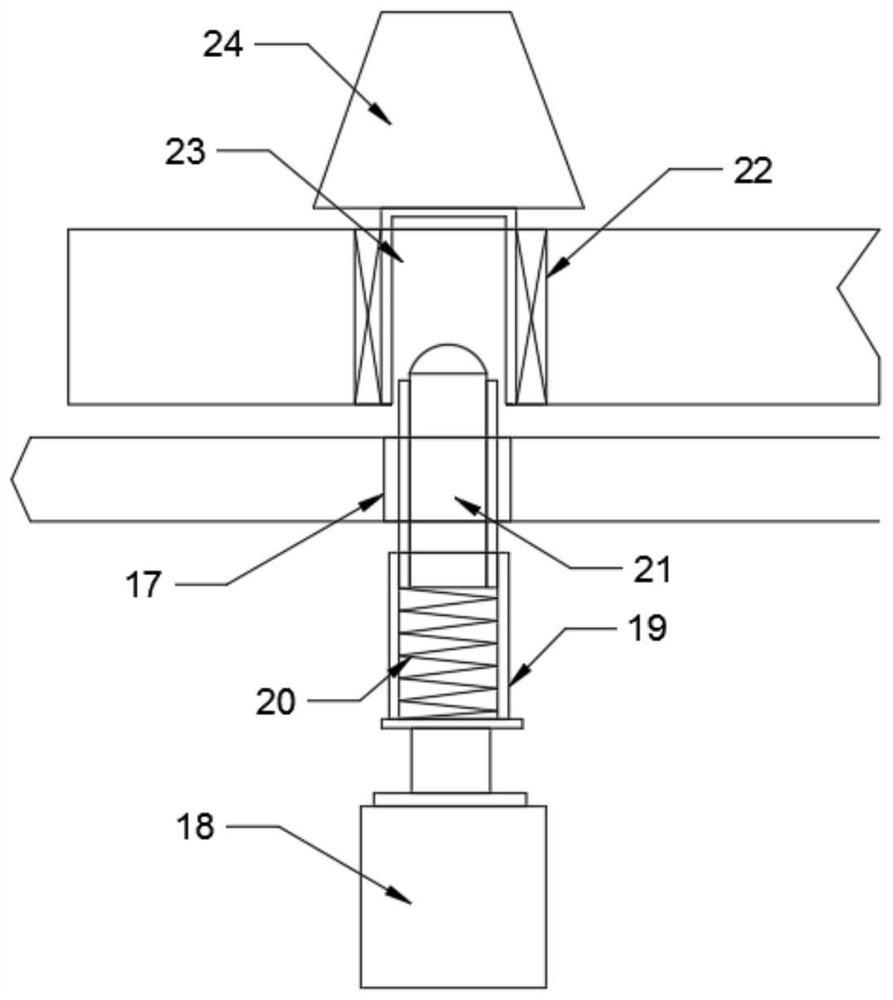

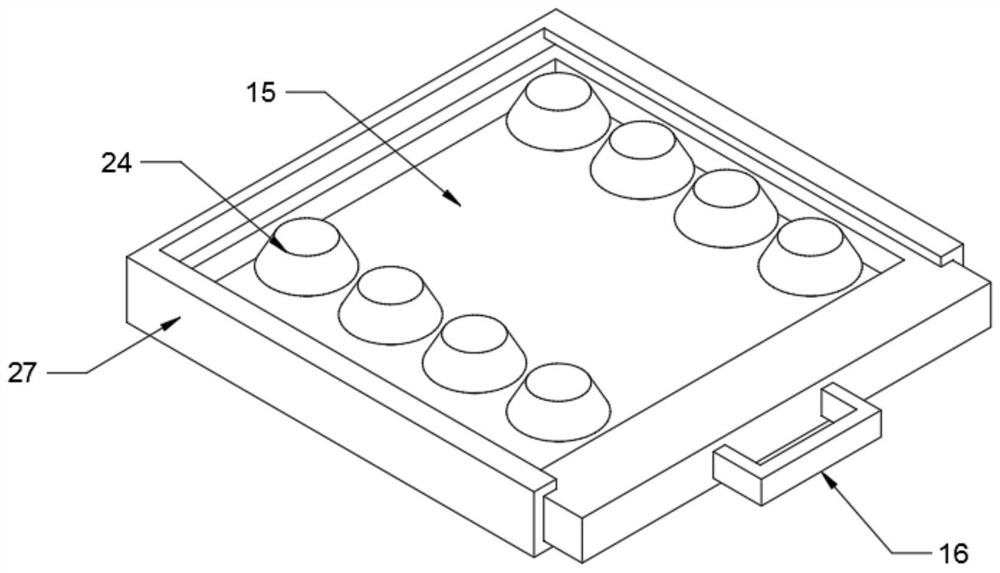

[0029]In the embodiment of the present invention, a LED product spraying equipment includes a workbench 1, a spray head 12 and a support plate 15, a support frame 14 is installed in the middle of the upper end of the workbench 1, and a limit hole 17 is provided on the upper surface of the support frame 14 to support A rotating motor 18 is installed at the inner bottom of the frame 14, a first fixed cylinder 19 is installed at the front end of the rotating motor 18, a spring 20 is installed at the inner bottom of the first fixed cylinder 19, and a limit rod 21 is installed at the top of the spring 20; Slide rail 27 is installed, and support plate 15 is installed on the inside of slide rail 27, and support plate 15 right end is provided with handle 16, and support plate 15 inboard is equipped with rolling bearing 22, and rolling bearing 22 inboard is installed with second fixed tube 23, and second fixed tube 23 The top is equipped with a fixed seat 24; the inner bottom of the sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com