Method for detecting setting effect of packer in salt-cavern gas storage

A detection method and a packer technology, which are applied in the direction of measuring the increase and decrease rate of the fluid, and using the liquid/vacuum degree to measure the liquid tightness, etc., can solve the problem of not meeting the requirements of long-term safe operation of the underground gas storage in salt caverns, etc. problem, to achieve the effect of cost-effective and cheap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

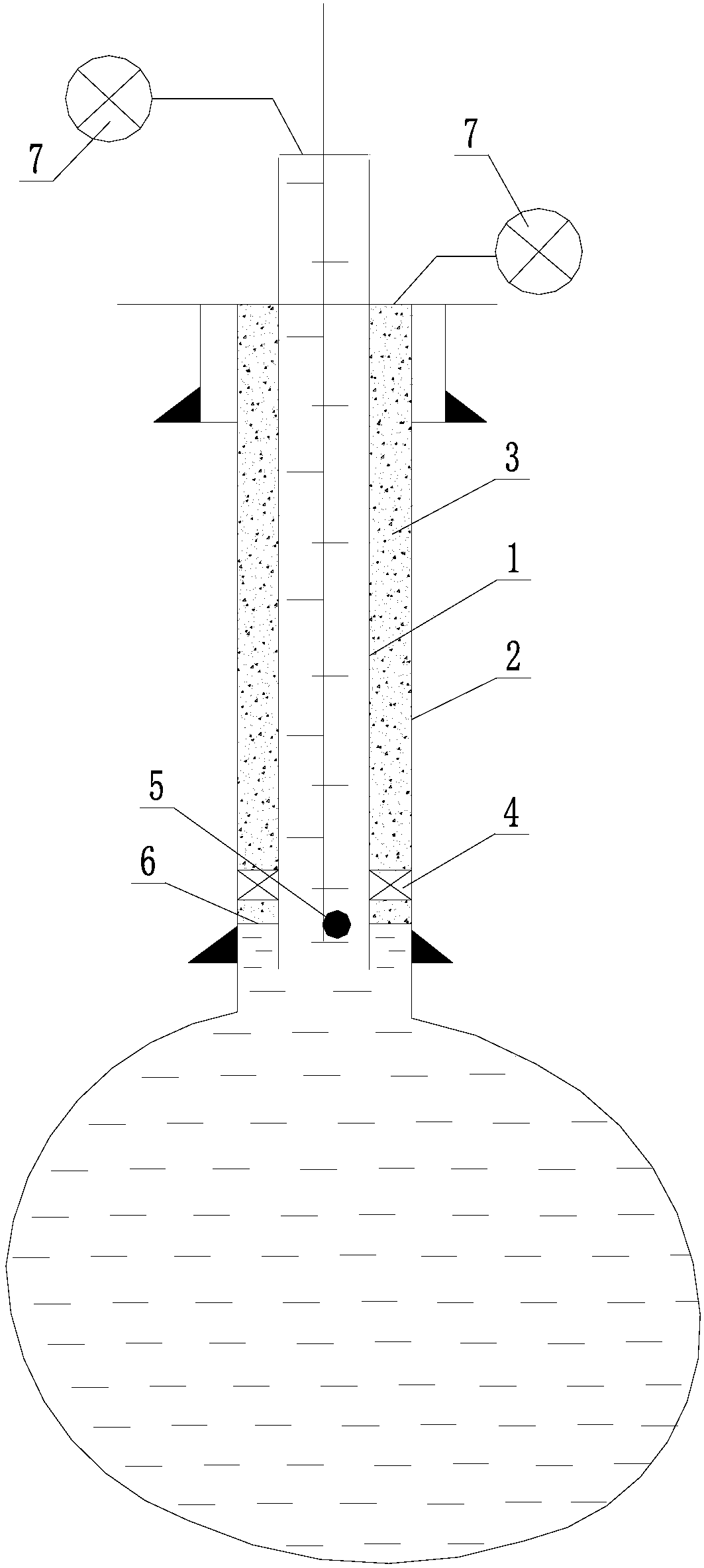

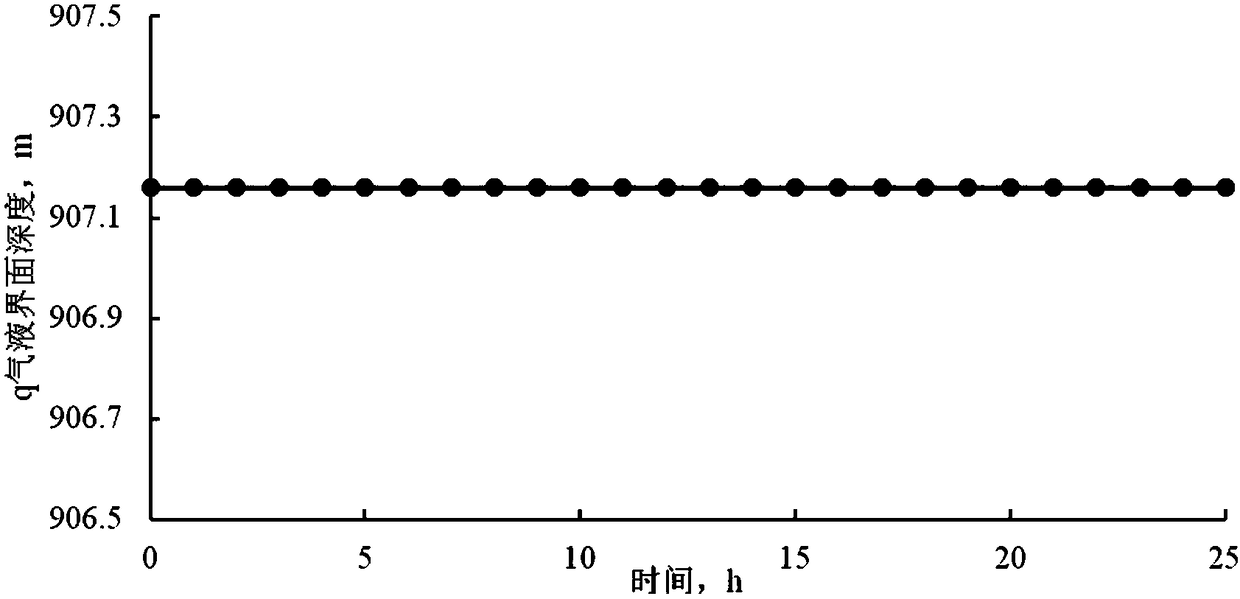

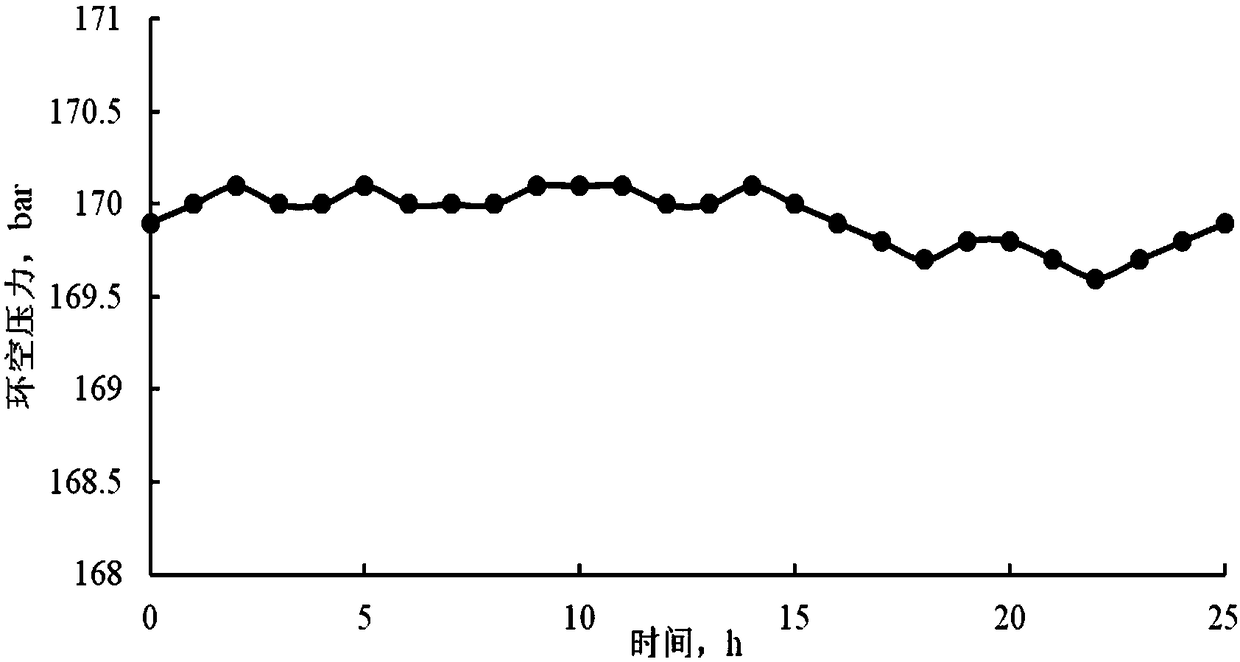

[0039]Example: After the injection-production casing 1 is run in and the well is washed, nitrogen is injected into the annulus 3, and the brine is pressed to 6 m below the set position of the packer 4 at 901.20 m, that is, 907.20 m. After the sealing pressure is 25MPa and the pressure is maintained for 30min, the setting of the packer 4 is completed, and then nitrogen is continuously injected into the annulus 3 for pressurization. The upper limit pressure of the salt cavern gas storage in this example is 17MPa. About 1.7MPa, so the wellhead pressure in the annular space 3 should reach 17MPa. After 2 hours, the gas-liquid interface detection equipment 5 is lowered into the injection-production casing 1 to detect the packer between the injection-production casing 1 and the production casing 2 The depth of gas-liquid interface 6 under 4 is 907.16m. At this time, the wellhead pressure of injection-production casing 1 is 0.2MPa, and the wellhead pressure of annular space 3 is 17MPa....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com