Coiled tubing tubular column device and brine discharging and capacity expanding method thereof for salt cavern underground gas storage reservoir

An oil pipe and pipe string technology, which is applied in the fields of oil and gas storage and transportation and resource development, can solve the problems of cavity volume loss, inability to discharge brine, and pipe string blockage, and achieve obvious economic benefits and the effect of increasing gas storage volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

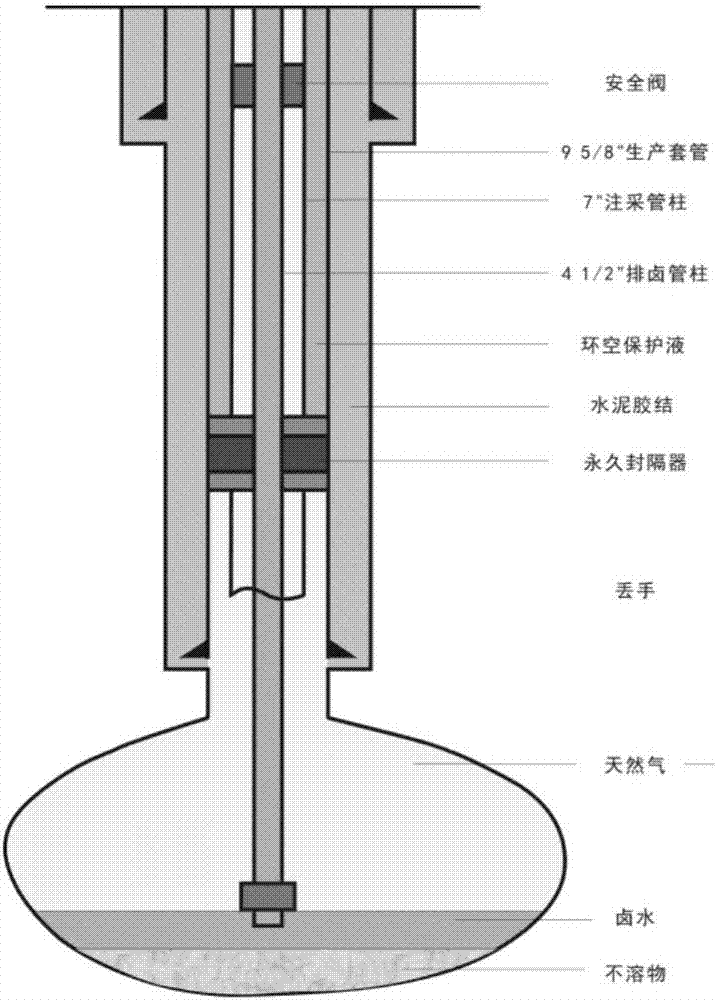

[0040] A coiled tubing string device, including a coiled tubing 1, a tubing outer card connector 2, a weighted tube 3, a hydraulic safety joint 4, and a rotary flushing tool 5. The schematic diagram of its structure is as follows: Figure 4 As shown, the bottom end of the coiled tubing 1 is connected to the weighted pipe 3 through the outer card connector 2 of the oil pipe, and the other end of the weighted pipe 3 is connected to the rotary flushing tool 5 through the hydraulic safety joint 4 .

[0041] Coiled tubing adopts the outer diameter Ф50.8mm, wall thickness 4.45mm, inner diameter 41.9mm, steel grade CT-90, and the outer card connector of the tubing adopts the products shown in Table 1, such as Figure 5 shown.

[0042] Table 1 Coiled tubing outer card connector parameters

[0043] Coiled tubing size

Tool diameter

Tool inner diameter

quantity

Bottom connection buckle type

place of origin

2.00"

2-7 / 8"

1.5"

1

2-3 / 8"PAC

...

Embodiment 2

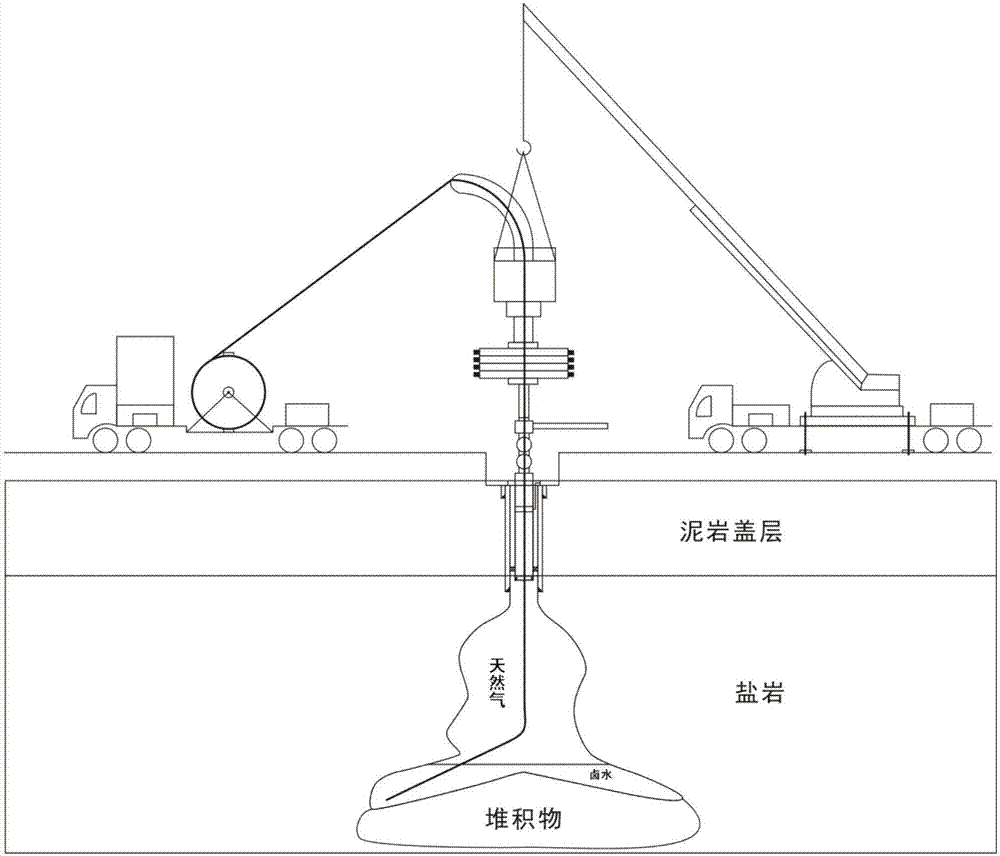

[0048] A method for brine discharge and capacity expansion of a salt cavern underground gas storage, the steps of which are:

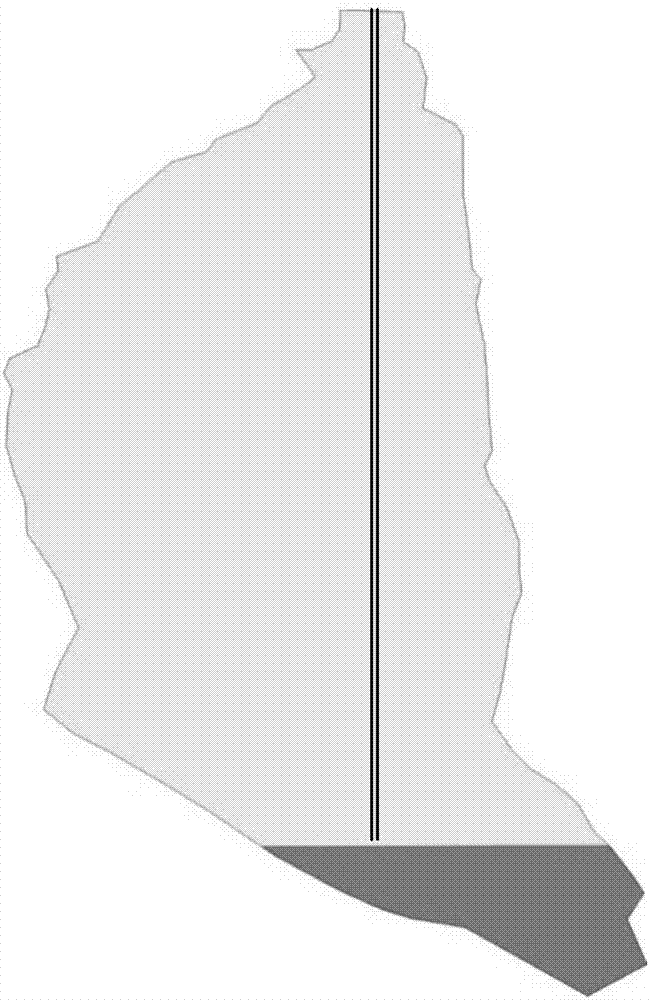

[0049] 1. Use the conventional gas injection and brine removal technology to carry out brine removal operations on the salt cavern underground gas storage. Based on the sonar measurement and gas injection and brine removal results, select expansion wells from the existing injection and production gas wells of the salt cavern underground gas storage Injection-production wells with large room for capacity expansion and good economic benefits of capacity expansion are used as target wells for capacity expansion. Taking a four port of Jintan Gas Storage as an example, the conventional gas injection and brine discharge cavity has been completed. The utilization rate of the cavity after conventional gas injection and halogen discharge varies from high to low, ranging from 70% to 97%. Less, 7000~65000m 3 , if 80% of the fluid in the cavity is discharged, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com