A hydraulic energy storage device with controllable input-output characteristics

A technology of hydraulic energy storage and output characteristics, applied in fluid pressure actuating devices, fluid pressure actuating system components, servo motors, etc., to solve problems such as uncontrollable motion, inability to switch energy storage capabilities, and inability to switch energy storage capabilities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the drawings and embodiments.

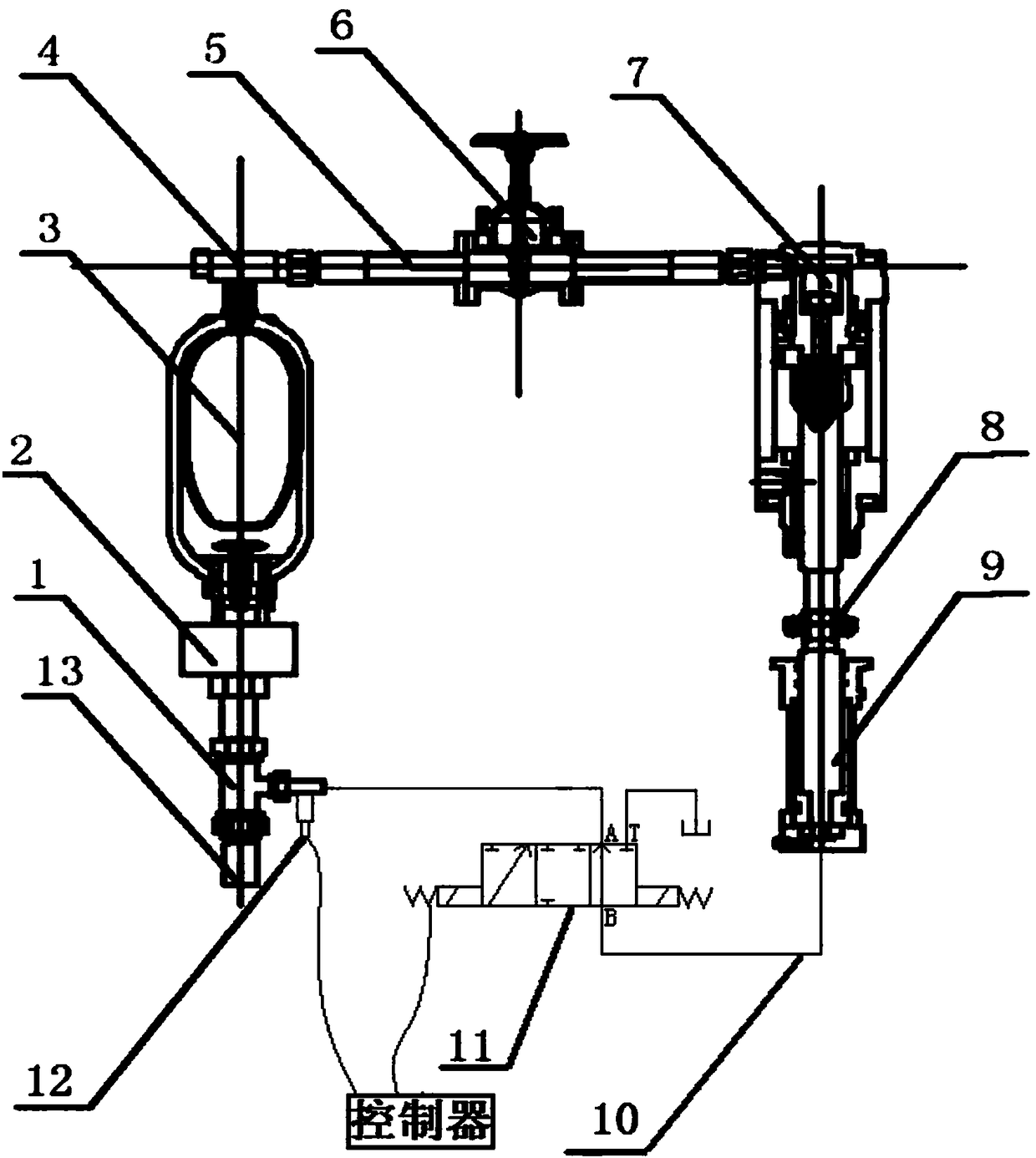

[0021] Such as figure 1 As shown, an input-output characteristic controllable hydraulic energy storage device includes a gas hydraulic accumulator 3 (the gas hydraulic accumulator 3 includes a pipeline vibration absorber, a gas-liquid direct contact type, a piston type, a diaphragm In this embodiment, the gas-type hydraulic accumulator 3 is a bladder-type accumulator) and a fuel tank. The liquid interface 2 of the gas-type hydraulic accumulator 3 is connected to the first port of the three-way pipe 1, The gas port 4 is connected to the gas source port of the single-acting pneumatic cylinder 7 through the gas pipe 5. The second port of the three-way pipe 1 is the liquid inlet and outlet 13 of the entire device. The gas pipe 5 is provided with a stop valve 6 and the piston of the single-acting pneumatic cylinder 7 The rod is connected to the piston rod of the single-act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com