Underground gas storage well shaft and its fixing method

A gas storage well and wellbore technology, which is applied to the wellbore of gas underground gas storage well and its fixing field, can solve the problems of difficult construction, poor safety, inconvenient maintenance, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

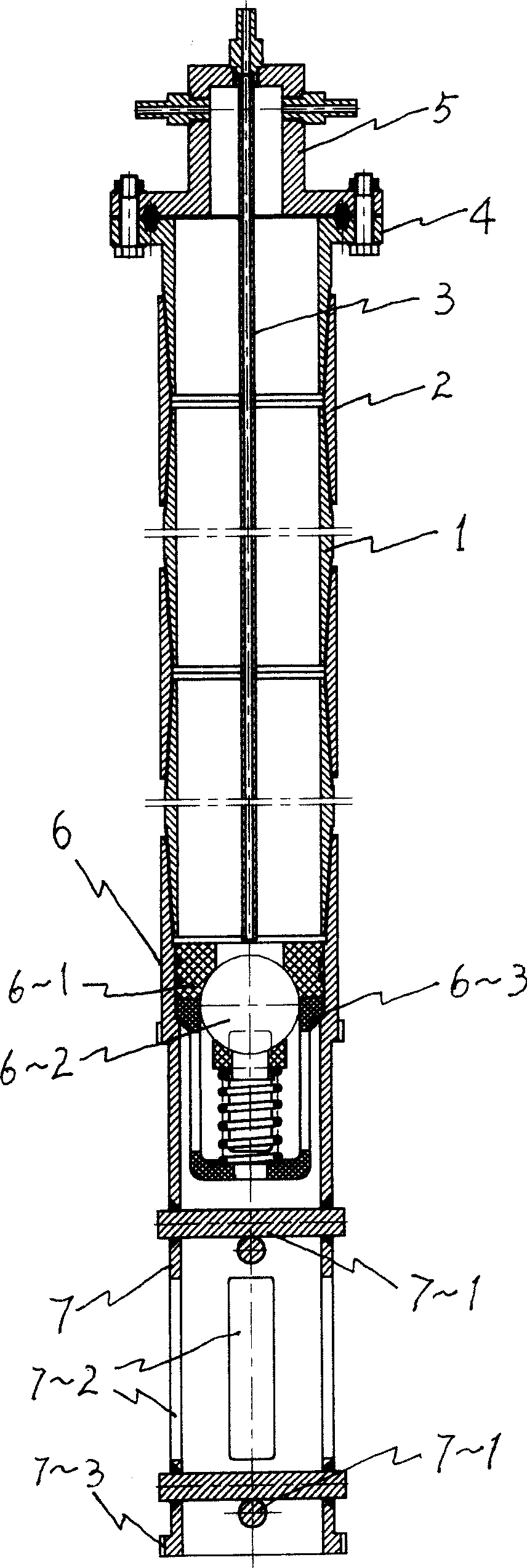

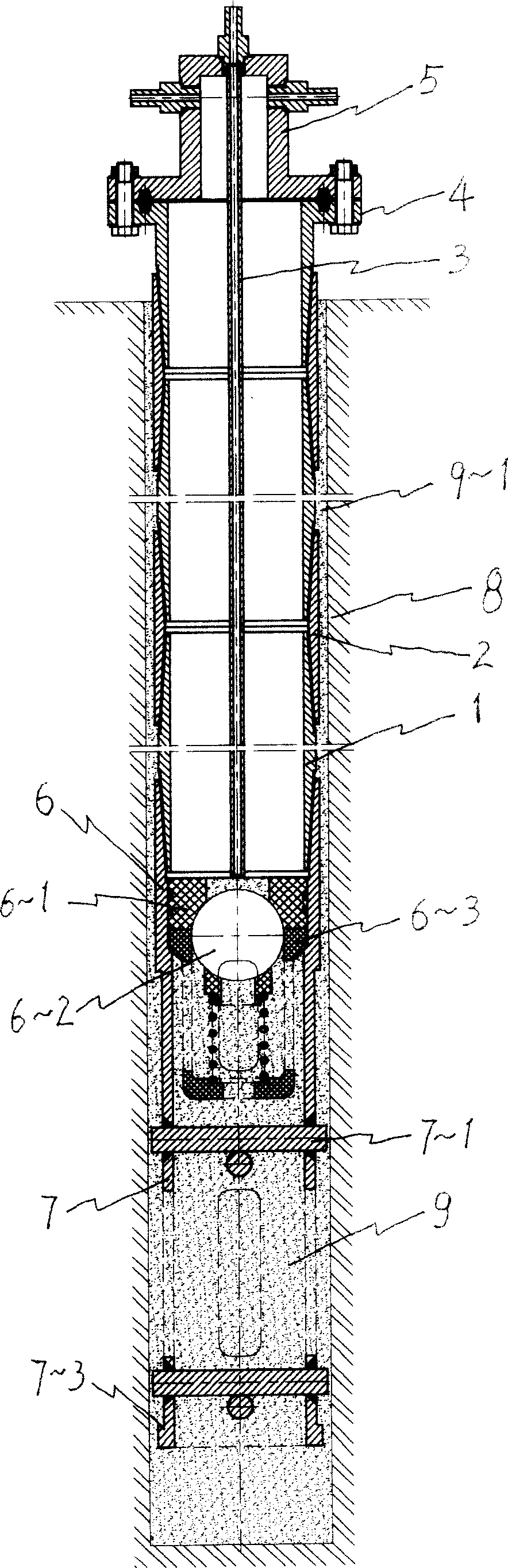

[0015] Taking the wellbore with an outer diameter of 7 (177.8mm) and a total effective gas storage length of 120m as an example:

[0016] The cylinder body 1, the connecting sleeve 2, the drain pipe 3, the wellhead flange 4, and the four-way control head 4 are all the same as the background technology. The valve body 6 in this embodiment adopts a 7-hour conduit back pressure valve for drilling in oil and gas fields; the fixed frame 7 adopts the same 7-hour conduit as the cylinder 1 and is welded to the lower mouth of the valve body 6, the axis height is 1200mm and passes through two sets of ribs Diameter is the cross bar 7-1 of φ 30mm to strengthen, and 4 frame holes 7-2 of 800 * 50mm (high * wide) are opened symmetrically on the tube wall, and bottom ring 7-3 is a toothed bottom ring, external diameter φ 20mm.

[0017] The fixing method is as follows: first, according to the oil and natural gas drilling procedures and requirements, drill a foundation well with a diameter of φ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com