High pressure underground gas well shaft fixing method

A fixing method and technology for gas storage wells, which are used in wellbore lining, shaft equipment, earth-moving drilling, etc., can solve problems such as threats to the safety of facilities and staff, inability to pour cement slurry, and impact on service life, and promote perfusion and filling. Effect, reliable installation and fixing method, prolonging service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

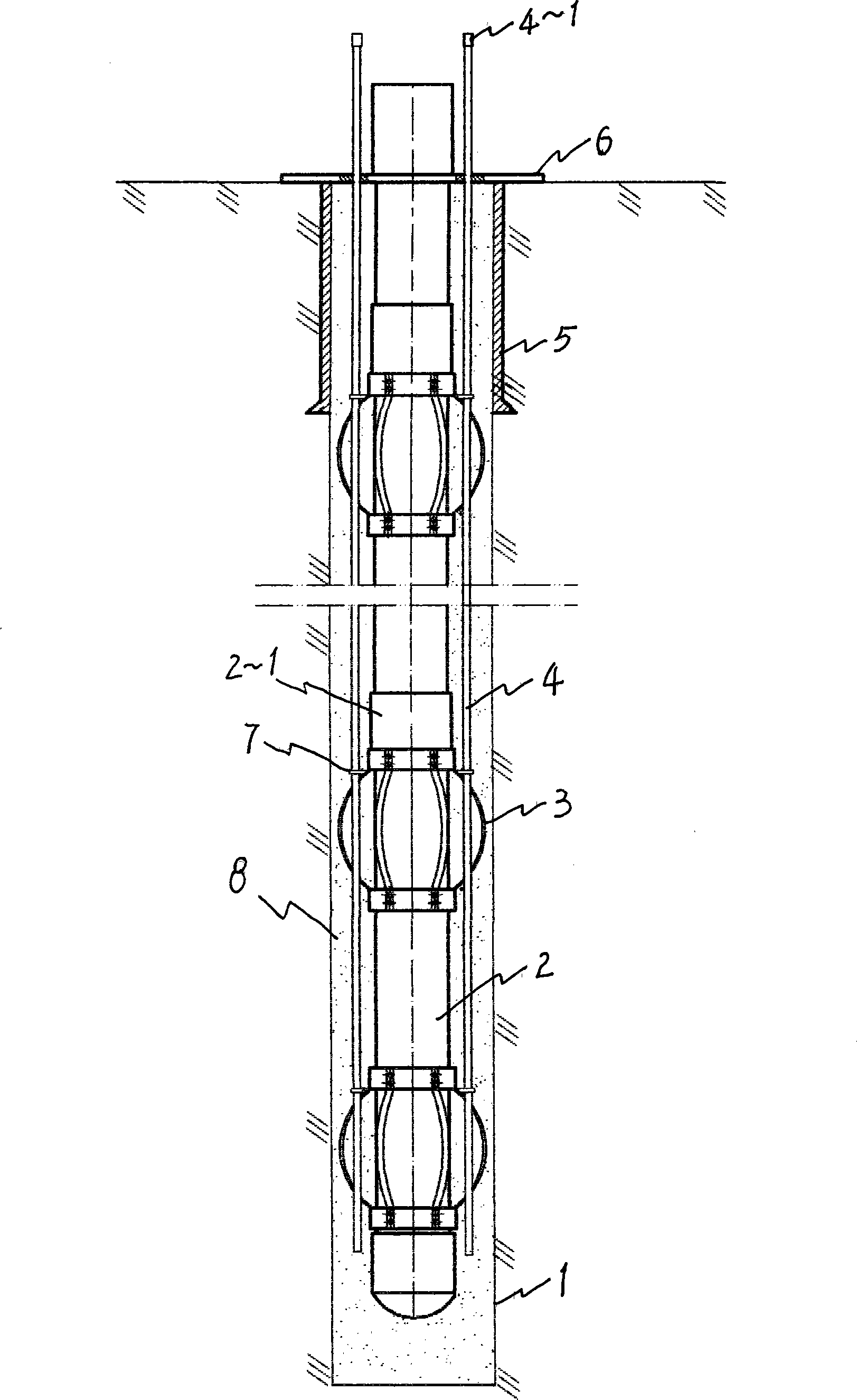

[0011] Embodiment 1: Take the gas storage well that the outer diameter of the gas storage shaft 2 is 7 o'clock (177.8 mm), the total length of the well shaft is 130 m, and the basic well 1 is drilled with a 104 / 5 o'clock (274.32 mm) drill bit as an example:

[0012] A. Lower wellbore and grouting pipe: set a centralizer 3 with an outer diameter of φ268mm and a height of 200mm at each connecting sleeve 2-1 on the wellbore 2, and a high-pressure water injection pipe with a diameter of φ40mm for fire protection in this embodiment. , set 3 pieces at intervals of 120° and fix them with the wellbore 2 through the fixed rings 4-2; The upper part of the pipe 4 is fixed on the surface conduit 5;

[0013] B. Injecting cement slurry: Fill the wellbore with clean water, then connect the three grouting pipes 4 to the mud pumps with output pressures of 3.5Mpa, 6Mpa and 8.5Mpa respectively, then start the mud pump, and use oil well cement according to the conventional method The prepared de...

Embodiment 2

[0015] The wellbore 2 of the gas storage well, the foundation well 1, and the centralizers 3 in this embodiment are the same as in the embodiment 1; the grouting pipe 4 adopts a steel pipe with an outer diameter of φ40mm, two symmetrically arranged and fixed to the wellbore 2 through the fixing rings 4-2, and the two The inlet ends of the grouting pipes 4 are respectively connected to the mud pumps of 5Mpa and 8Mpa; the rest are also the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com