Device for measuring frictional resistance coefficient of gas in underground gas storage well and monitoring vibration of tubular column

A vibration device and frictional resistance technology, which is applied in the fields of gas frictional resistance coefficient measurement of underground gas storage wells and pipe string vibration monitoring devices, and can solve problems such as structural failure and scrapping of underground gas storage wells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

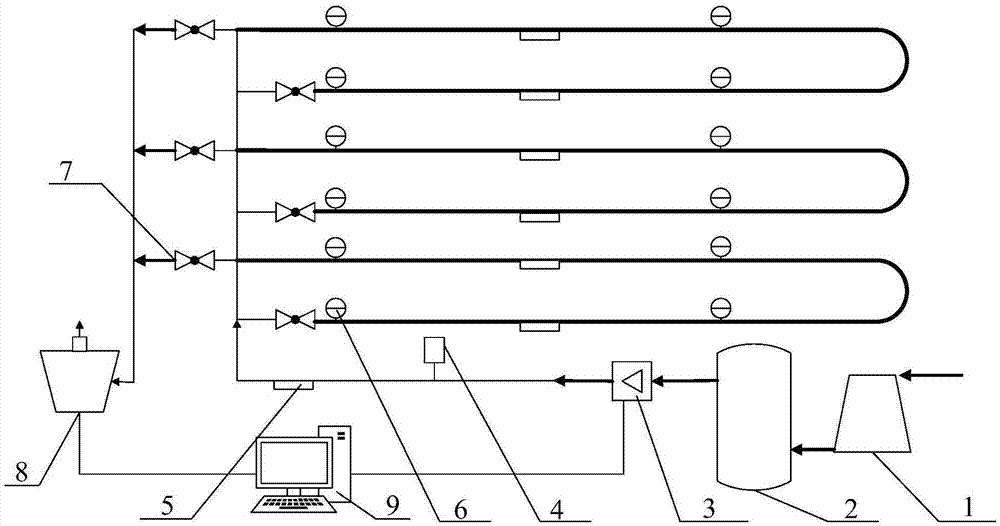

[0018] Such as figure 1 As shown, a horizontal gas well gas injection and production process simulation and vibration characteristics analysis experimental device, including: a horizontally placed test pipeline, a gas supply system for providing gas flow, a data acquisition system, and an electric ball valve installed at one end of the test pipeline.

[0019] The gas supply system consists of a pipeline, a screw compressor, a gas buffer tank, and a gas mass flow controller. According to the actual situation, the air can be compressed into the gas buffer tank through the screw compressor.

[0020] The gas mass flow controller is installed behind the gas buffer tank and communicated with the computer to control the gas flow flowing into the test pipeline and prevent gas backflow.

[0021] The one-way valve is installed behind the gas mass flow controller to prevent gas backflow.

[0022] The data acquisition system is composed of a gas flow meter, a temperature sensor, a press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com