Method for pre-pumping coal roadway stripe gas of single soft protruded coal seam of unexploited area

A technology for outburst coal seam and gas extraction, which is applied in the field of pre-draining coal roadway strip gas in a single soft outburst coal seam in unmined areas, and can solve the problem that the soft and high outburst original coal seam cannot be applied, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

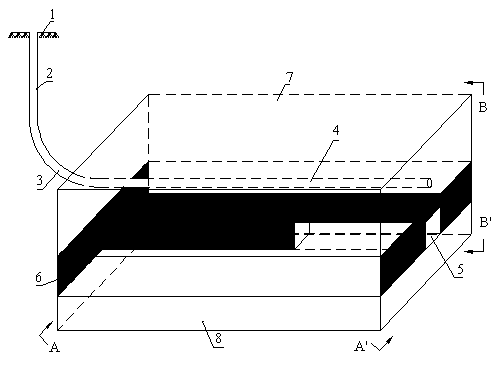

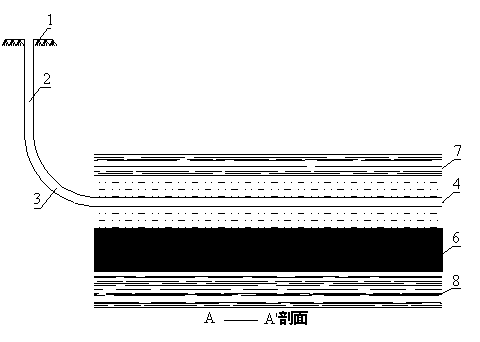

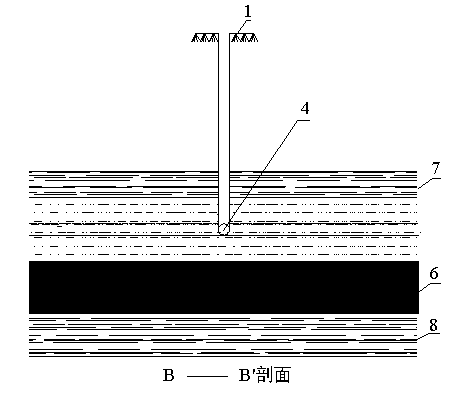

[0035] A method for pre-pumping coal lane strips of gas in a ground horizontal well to the roof of a single soft outburst coal seam in an unmined area. For the near-horizontal single, soft, low-permeability, high outburst coal seam 6 with a thickness of 5.7m and a buried depth of 685m, the failure type of the coal in this seam is Class V, the coal quality is mostly powdery, and the coal type is mylonitic coal; Content is 21m 3 / t, the gas pressure is 1.5MPa; the immediate roof 7 of the coal seam is sandy mudstone and silty rock, with a thickness of 1.96-9.97m, with an average thickness of 5.27m; the old roof is fine sandstone, with a thickness of 1.22-11.95m, with an average thickness of 5.05m; The immediate floor 8 of the coal seam is sandy mudstone or carbonaceous mudstone, with a thickness of 0.74-17.93 meters, with an average thickness of 7.00 meters. The old bottom is sandstone, with a thickness of 0.45-26.5 meters, with an average thickness of 10.70 meters. There is a lim...

Embodiment 2

[0042] A method for pre-pumping coal lane strips of gas in a ground horizontal well to a single soft outburst coal seam floor in an unmined area. For the nearly horizontal single, soft, low permeability and high outburst coal seam 6 with a thickness of 4.8m and a buried depth of 720m, the failure type of the coal in this seam is Type III, and the coal quality is mostly fragmented; the gas content is 14m 3 / t, the gas pressure is 1.2MPa; the immediate roof of the coal seam is black mudstone and carbonaceous mudstone, 2.8-7.2m thick, with an average thickness of 5.4m, and the old roof is medium-coarse sandstone, with a thickness of 8.1-12.3m, with an average thickness of 9.5m The immediate floor 8 of the coal seam is sandy mudstone or mudstone, 2.4-15.6 meters thick, with an average thickness of 10.3 meters, and the old bottom is sandstone, with a thickness of 3.5-27.8 meters, with an average thickness of 14.5 meters. Coal seam roof 7 has confined water in sandstone fissures of ...

Embodiment 3

[0049] The invention relates to a method for carrying gas in strips of coal roadways for pre-extraction of coal roadways by multi-branch horizontal wells on the ground to the roof and floor of a single soft outburst coal seam in an unmined area. For the near-horizontal single, soft, low-permeability, high-outburst coal seam 6 with a thickness of 6.68m and a buried depth of 700m, the failure type of the coal in this seam is Class IV, and the coal quality is mostly powdery and fragmented; the gas content is 28m 3 / t, the gas pressure is 1.7MPa; the immediate roof 7 of the coal seam is sandy mudstone, 2.6-6.9m thick, with an average thickness of 4.8m; the old roof is fine sandstone, with a thickness of 3.2-16.5m, with an average thickness of 8.4m; The sandy mudstone or carbonaceous mudstone is 2.4-15.6 meters thick, with an average thickness of 7.6 meters. The old bottom is sandstone, with a thickness of 1.8-20.6 meters, with an average thickness of 12.5 meters. The roof and floo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com