Double-wall sleeve suspension type high-pressure gas underground storing well installation method and structure thereof

A high-pressure gas and suspension technology, which is applied in mining equipment, earthwork drilling, storage equipment, etc., can solve the problems of poor sealing effect of natural gas and impossible removal of cement, and achieve the effect of avoiding self-pressurization and corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

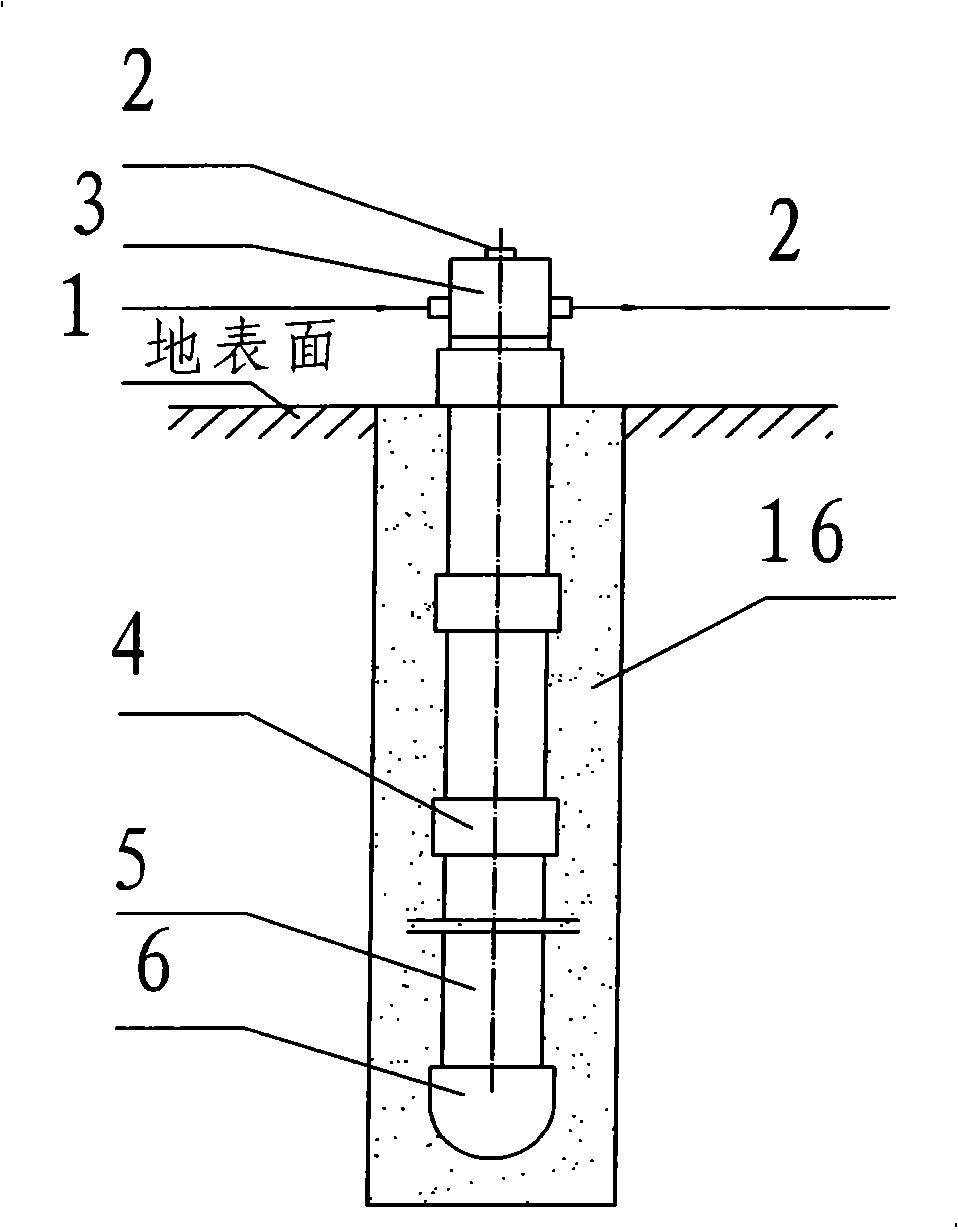

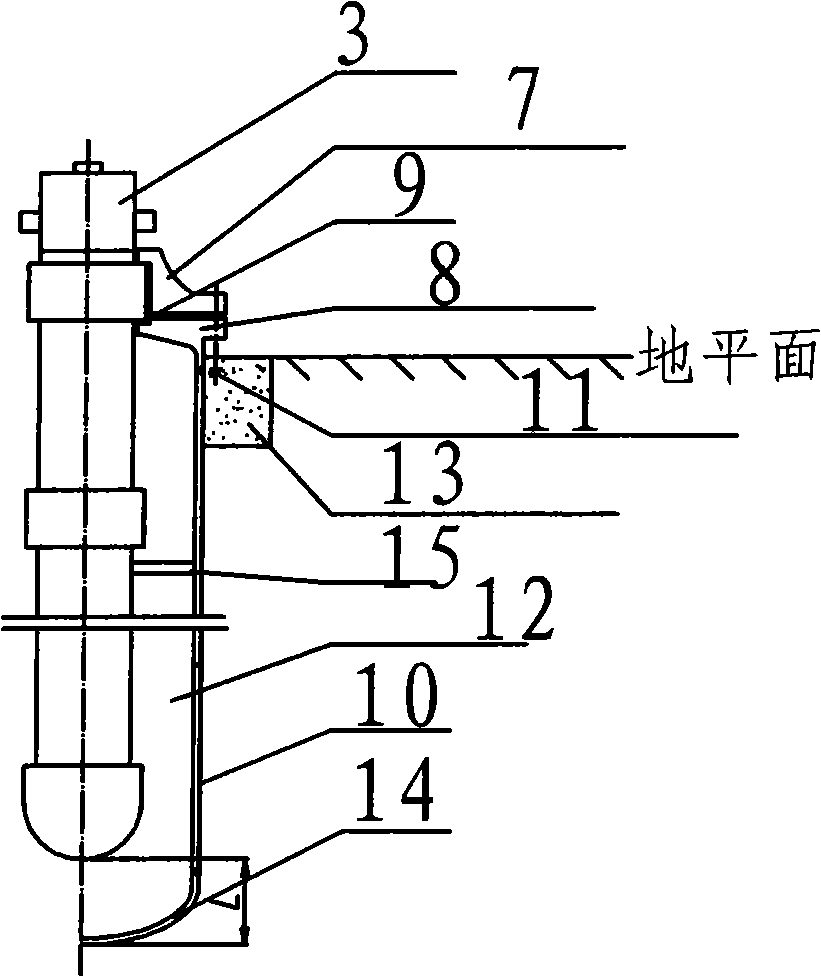

[0036] Drilling, the diameter of the well between the ground level and the hard soil layer is 1.6 times the diameter of the U-shaped barrel, the diameter of the rest of the well is 1.4 times the U-shaped barrel, and the drilling depth is the U-shaped barrel length + 20 meters (The deepening length is reserved for the wellbore collapse); firstly weld the lower head and the outer wellbore body, and then weld multiple outer wellbore bodies in turn to form a U-shaped body and sink it into the well. The uppermost end of the cylinder body is welded and connected with the flange of the special-shaped equipment on the lower side with grooves; cement is poured between the outer wall of the U-shaped cylinder body located at the ground surface and the hard soil layer and the drilling well wall to form a cementing layer and a ground surface. In the base layer, four anchor bolts are pre-buried in the base layer; the four anchor bolts are connected and fixed with the special-shaped equipment...

Embodiment 2

[0038] Drilling, the diameter of the well between the ground level and the hard soil layer is 1.8 times the diameter of the U-shaped barrel, the diameter of the rest of the drilling is 1.4 times the U-shaped barrel, and the drilling depth is the U-shaped barrel length + 20 meters (The deepening length is reserved for the wellbore collapse); firstly weld the lower head and the outer wellbore body, and then weld multiple outer wellbore bodies in turn to form a U-shaped body and sink it into the well. The uppermost end of the cylinder body is welded and connected with the flange of the special-shaped equipment on the lower side with grooves; cement is poured between the outer wall of the U-shaped cylinder body located at the ground surface and the hard soil layer and the drilling well wall to form a cementing layer and a ground surface. In the base layer, four anchor bolts are pre-buried in the base layer; the four anchor bolts are connected and fixed with the special-shaped equip...

Embodiment 3

[0040] Drilling, the diameter of the well between the ground level and the hard soil layer is 1.7 times the diameter of the U-shaped barrel, the diameter of the rest of the drilling is 1.4 times the U-shaped barrel, and the drilling depth is the U-shaped barrel length + 20 meters (The deepening length is reserved for the wellbore collapse); firstly weld the lower head and the outer wellbore body, and then weld multiple outer wellbore bodies in turn to form a U-shaped body and sink it into the well. The uppermost end of the cylinder body is welded and connected with the flange of the special-shaped equipment on the lower side with grooves; cement is poured between the outer wall of the U-shaped cylinder body located at the ground surface and the hard soil layer and the drilling well wall to form a cementing layer and a ground surface. In the base layer, four anchor bolts are pre-buried in the base layer; the four anchor bolts are connected and fixed with the special-shaped equip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com