Aluminum oxide warehousing system and conveying and storing method thereof

A kind of alumina storage bin technology, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of affecting the service life of storage bins, long alumina transportation distance, increasing floor space and storage bin cost, etc. Achieve the effect of eliminating the uneven force on the warehouse body, shortening the distance of material conveying, and increasing the flexibility of conveying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

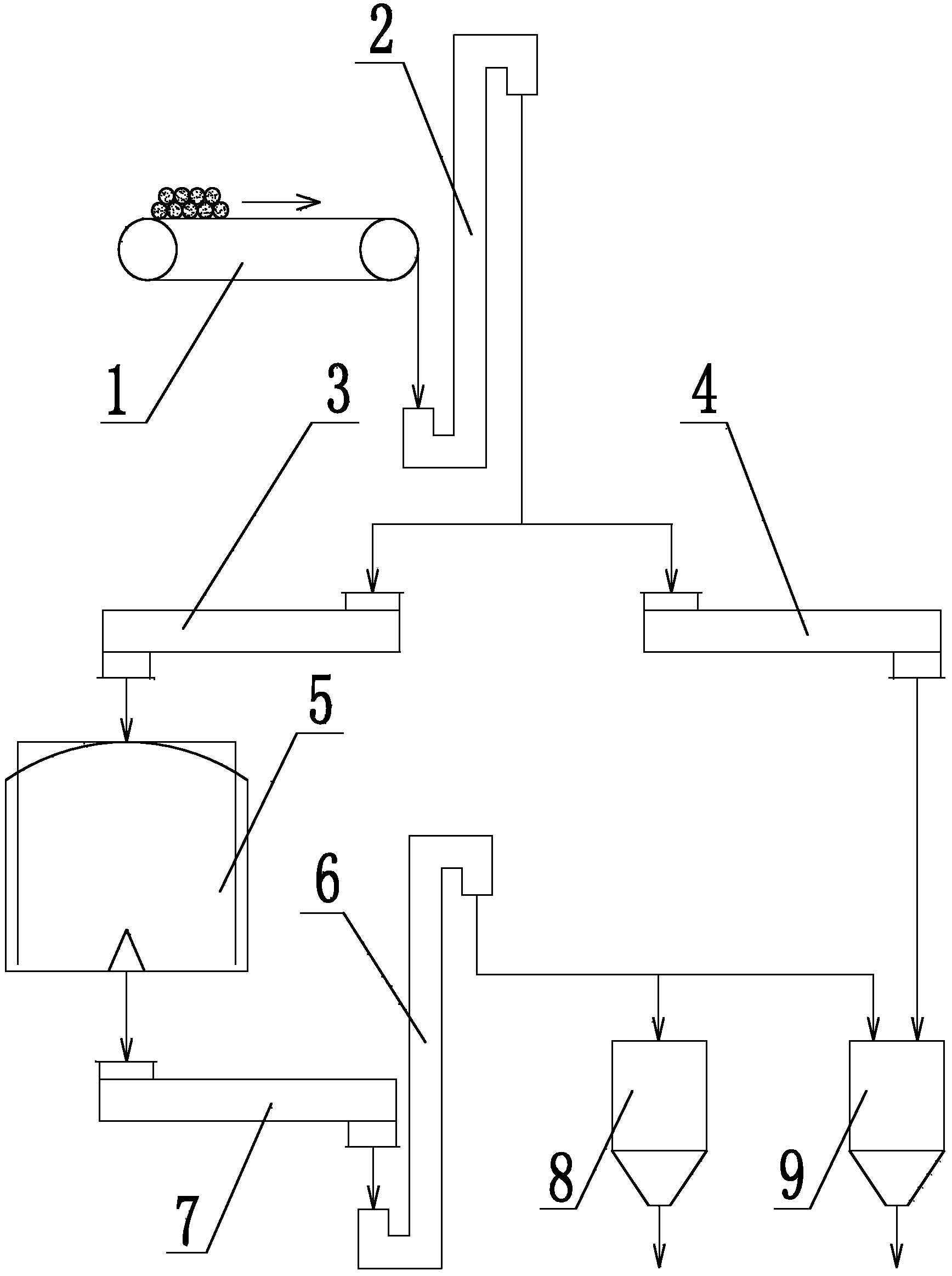

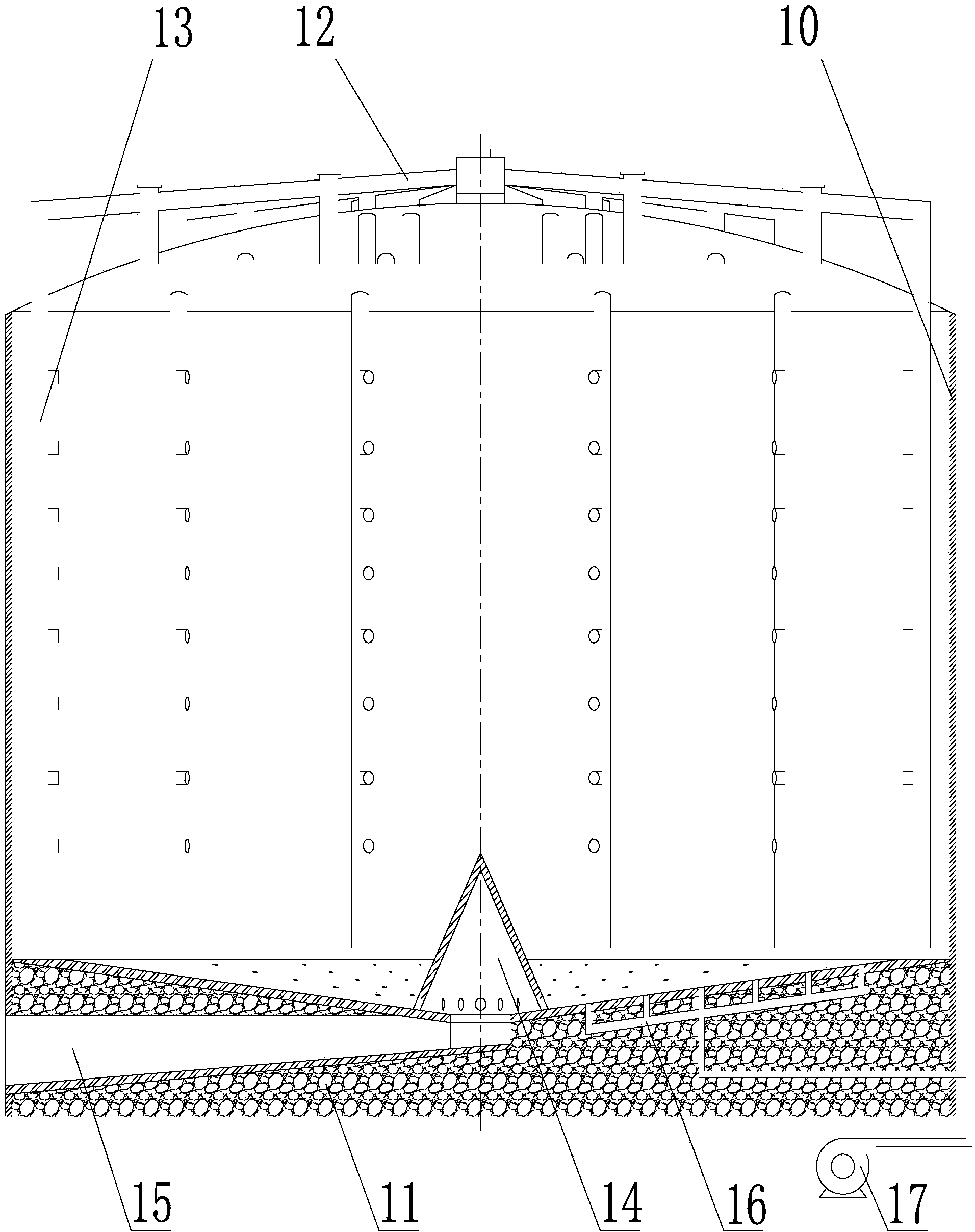

[0026] Such as figure 1 , 2 As shown, an alumina storage silo system includes a material storage part 5 and a material delivery part. The material storage part 5 includes a silo body 10, a top feeding pipe 12, a vertical feeding pipe 13 in the bin, and a discharge pipe. Chamber 14, the material conveying part includes a belt conveyor 1, a first bucket elevator 2, a first pneumatic chute 3, a second pneumatic chute 4, a second bucket elevator 6, and a third pneumatic chute 7 , Bulk buffer warehouse 8 and bag packaging buffer warehouse 9;

[0027] The warehouse top feeding pipe 12 of the material storage part 5 is fixedly mounted on the top of the warehouse body 10, the warehouse top feeding pipe 12 adopts a radial structure, and the radiation center of the warehouse top feeding pipe 12 is a feed inlet, The pipe body of the material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com