Polymer battery encapsulation method

A battery packaging and polymer technology, which is applied in the field of polymer battery packaging, can solve the problems of battery performance impact, difficult capacity, and difficulty in meeting customers' high standards, and achieve strong market competitiveness, large capacity increase space, and product benefits. Considerable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

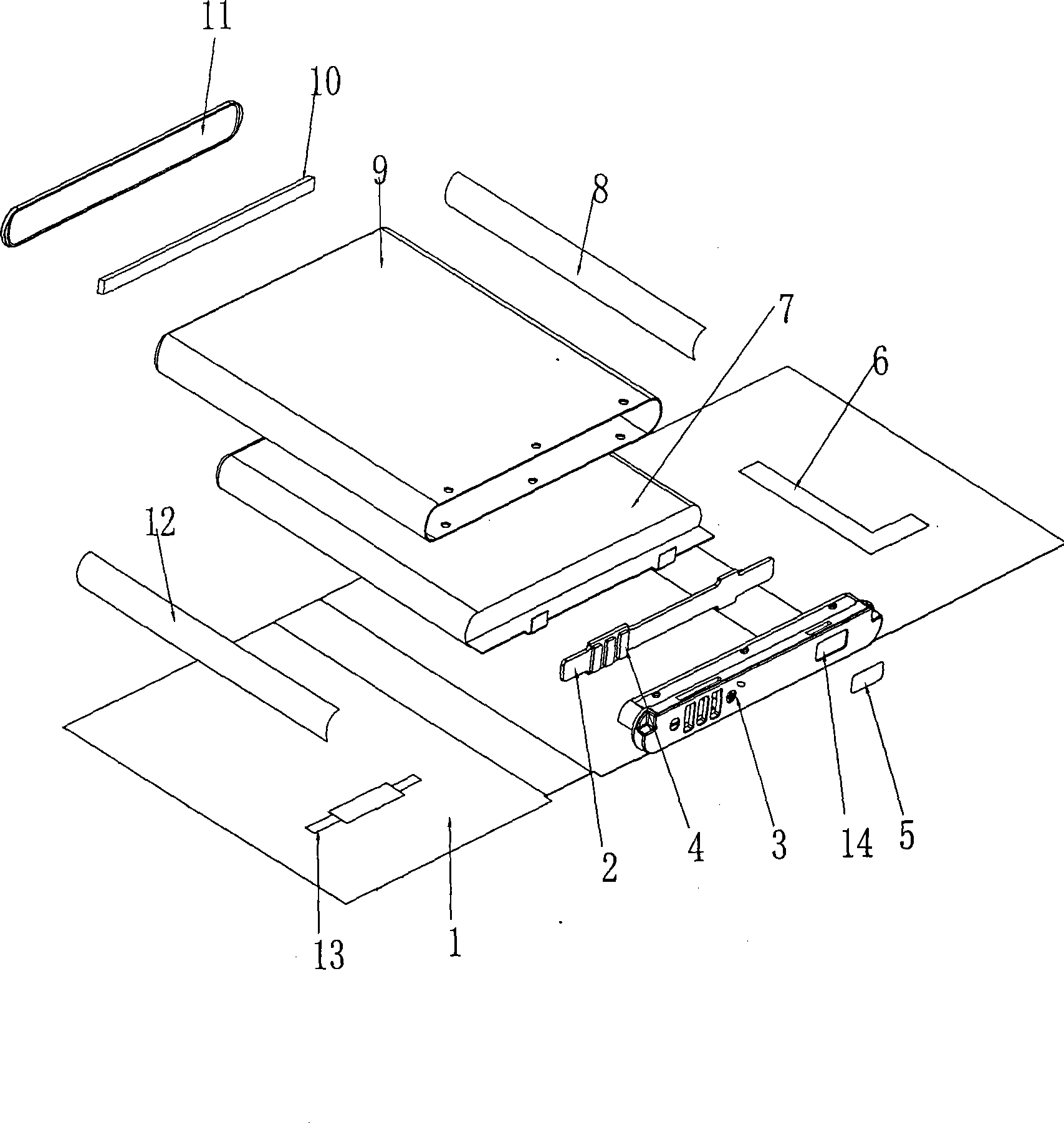

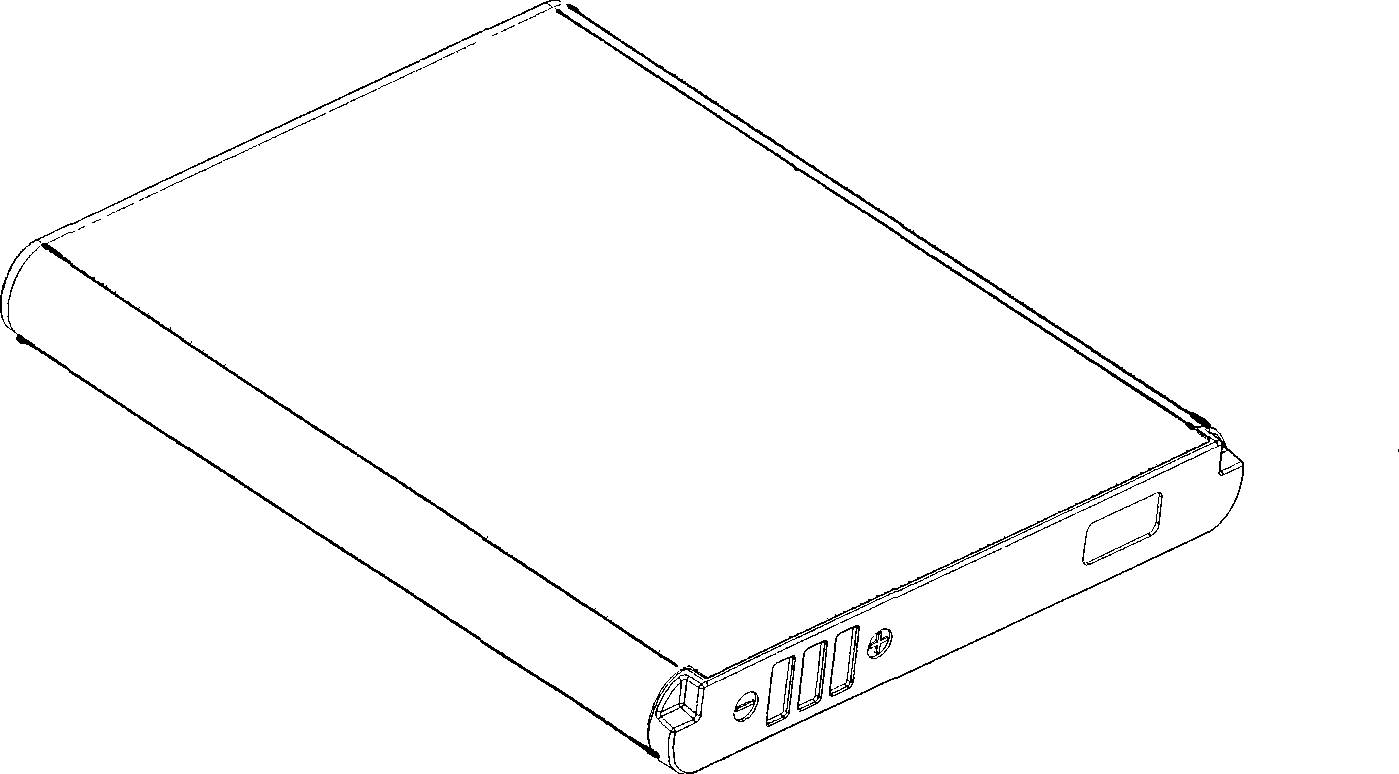

[0017] Combine below figure 1 with figure 2 , The method of the present invention will be described in detail.

[0018] A polymer battery packaging method includes the following steps:

[0019] (1) Stick EVA foam 8, 12, 10 on both sides and bottom of the battery core 7. The main function of the EVA foam 8, 12, 10 is to prevent the battery core 7 from moving in the aluminum shell 9. This step is optional. If the inner dimension of the aluminum shell 9 matches the outer dimension of the battery core 7, the EVA foam 8, 12, 10 may not be attached;

[0020] (3) Connect the PTC13 in series with the positive or negative electrode of the battery cell 7, and use the L-shaped nickel sheet 6 to connect the PTC13 with the PCM board 2. The main function of the PTC13 is to automatically disconnect when the battery temperature is too high. This step is also optional.

[0021] (4) A PCM board 2 is arranged on the upper and bottom surface of the battery core 7 to electrically connect the PCM boar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com