Crankcase structure for needling machine

A crankcase, acupuncture machine technology, used in acupuncture machines, mechanical equipment, textiles and papermaking, etc., can solve problems such as machine vibration, substantial complexity, and lateral oscillation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

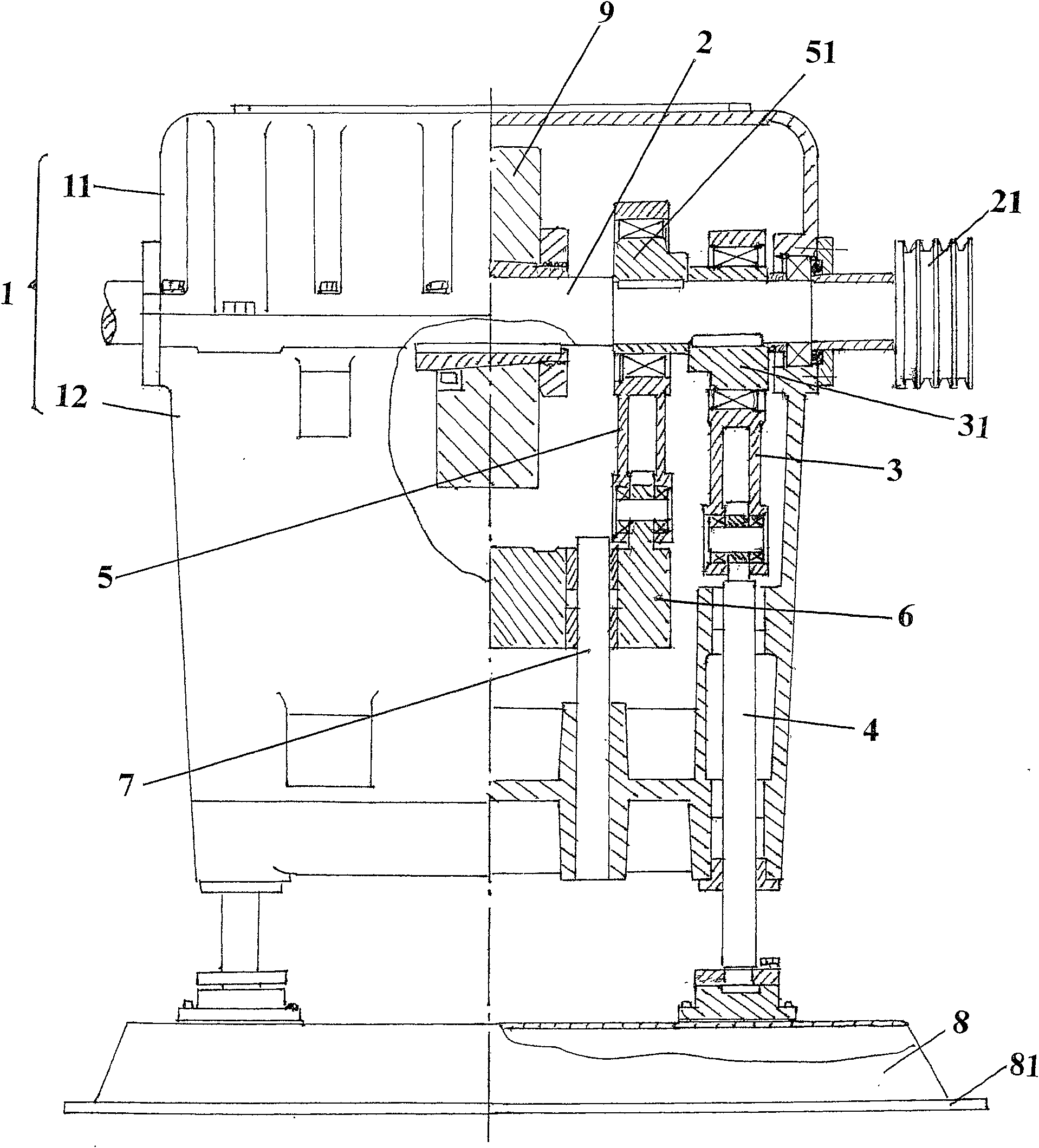

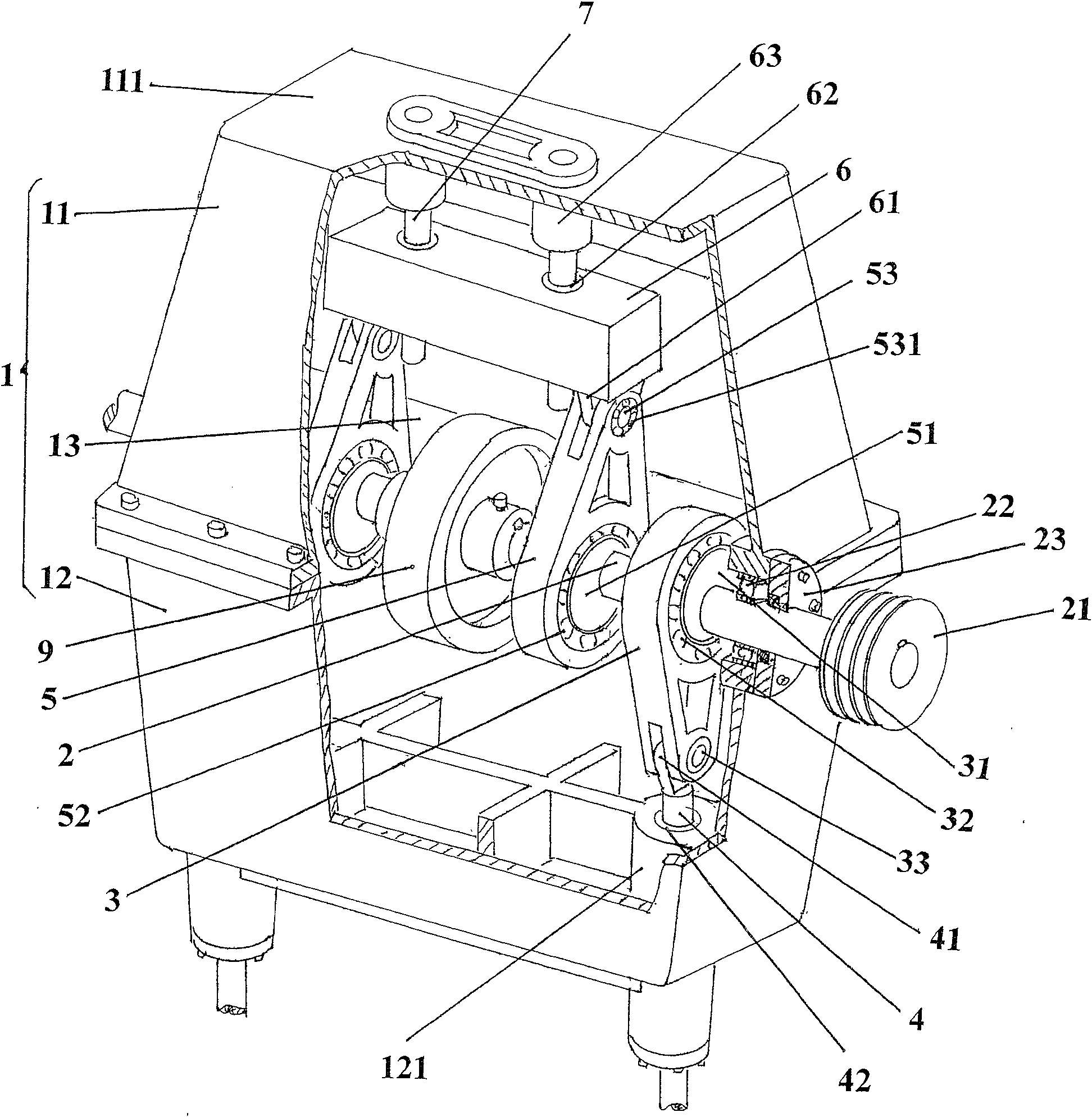

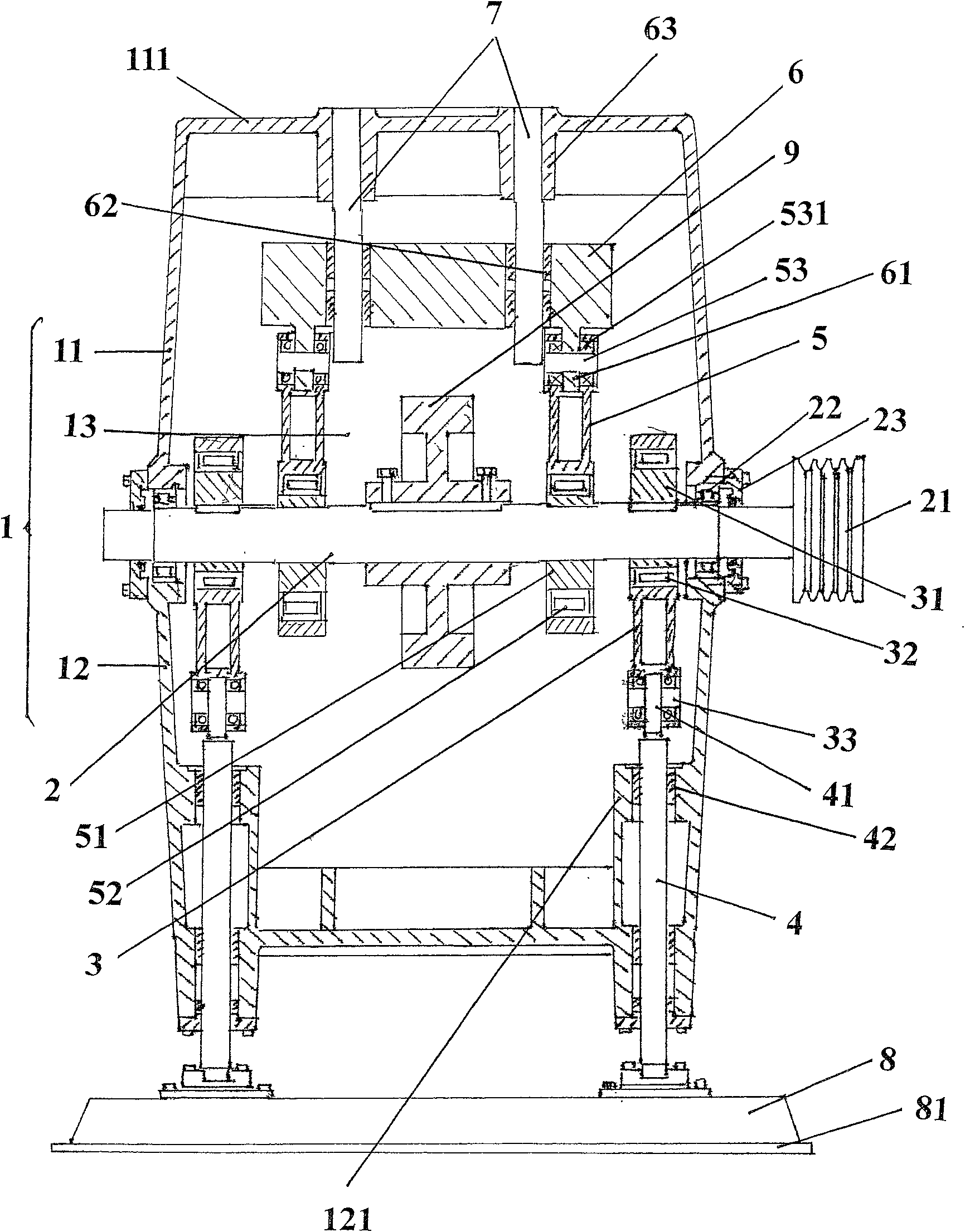

[0016] see figure 2 with image 3 , the given box 1 is composed of upper and lower shells 11, 12 cooperating with each other, and the cavities of the upper and lower shells 11, 12 jointly constitute the box cavity 13 of the box 1. Depend on figure 2 Clearly, since the shapes of the upper and lower casings 11, 12 are substantially the same, they can be said to be symmetrical structures. A main shaft 2 is located in the middle of the height direction of the box body 1, more precisely, it is located at the mutual joint position of the upper and lower housings 11, 12, specifically: the two ends of the main shaft 2 respectively pass through the first bearing 22 and add The shaft cover 23 realizes pivoting with the box body. Taking the illustrated position as an example, the main shaft 2 is fixed with a transmission wheel 21 at the left end extending out of the box body 1 , while the right end of the main shaft 2 also extends out of the box body 1 . The reason why the right en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com