Matching structure of electric car battery pack and car body

A technology of matching structure and electric vehicle, applied in the arrangement of cooling combined power unit, secondary battery, electric power unit, etc., can solve the problems of occupying luggage space, high load, uneven load distribution of front and rear axles, etc. Easy disassembly, efficient use of space, and the effect of increasing cruising range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing.

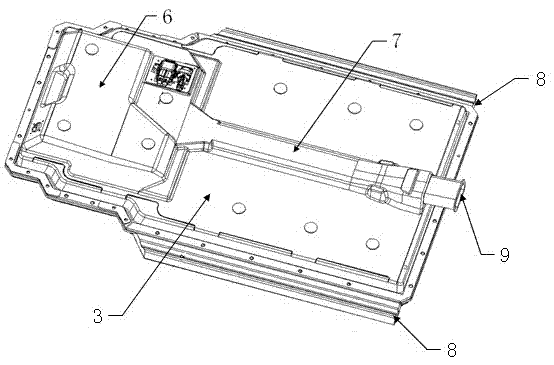

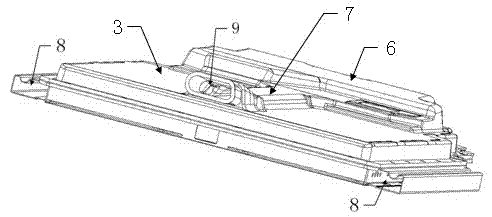

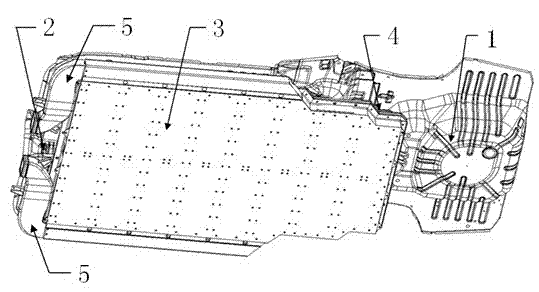

[0019] see figure 1 and figure 2 As shown in the matching structure between the battery pack and the vehicle body of an electric vehicle, the battery pack 3 is arranged at the central position under the floor of the vehicle body, the front end is directly below the instrument panel, and the rear end is close to the trunk 1. In this way, the battery pack 3 can be fully utilized. This part of the space after the gas system is removed; the front protrusion 6 on the front of the battery pack 3 corresponds to the underside of the middle channel 2 on the body floor, and the rear protrusion 7 on the rear of the battery pack 3 corresponds to the position of the rear seats. The bottom of 4 corresponds; the battery pack 3 is connected to the body floor by bolts, so that the battery pack and the body floor are closely attached.

[0020] Further, an air inlet pipe is provided on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com