Fabrication method of soft pack battery

A soft-pack battery and cell technology, applied in the field of lithium-ion batteries, can solve the problem of easy removal of the second cover, and achieve the effects of reducing the force on the tape, reducing damage, and improving the yield of the battery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] A method for preparing a pouch battery, comprising the steps of:

[0026] 1) Perform homogenization, coating, rolling, die-cutting, and lamination according to the cell preparation process to ensure that the process is qualified and obtain the cell.

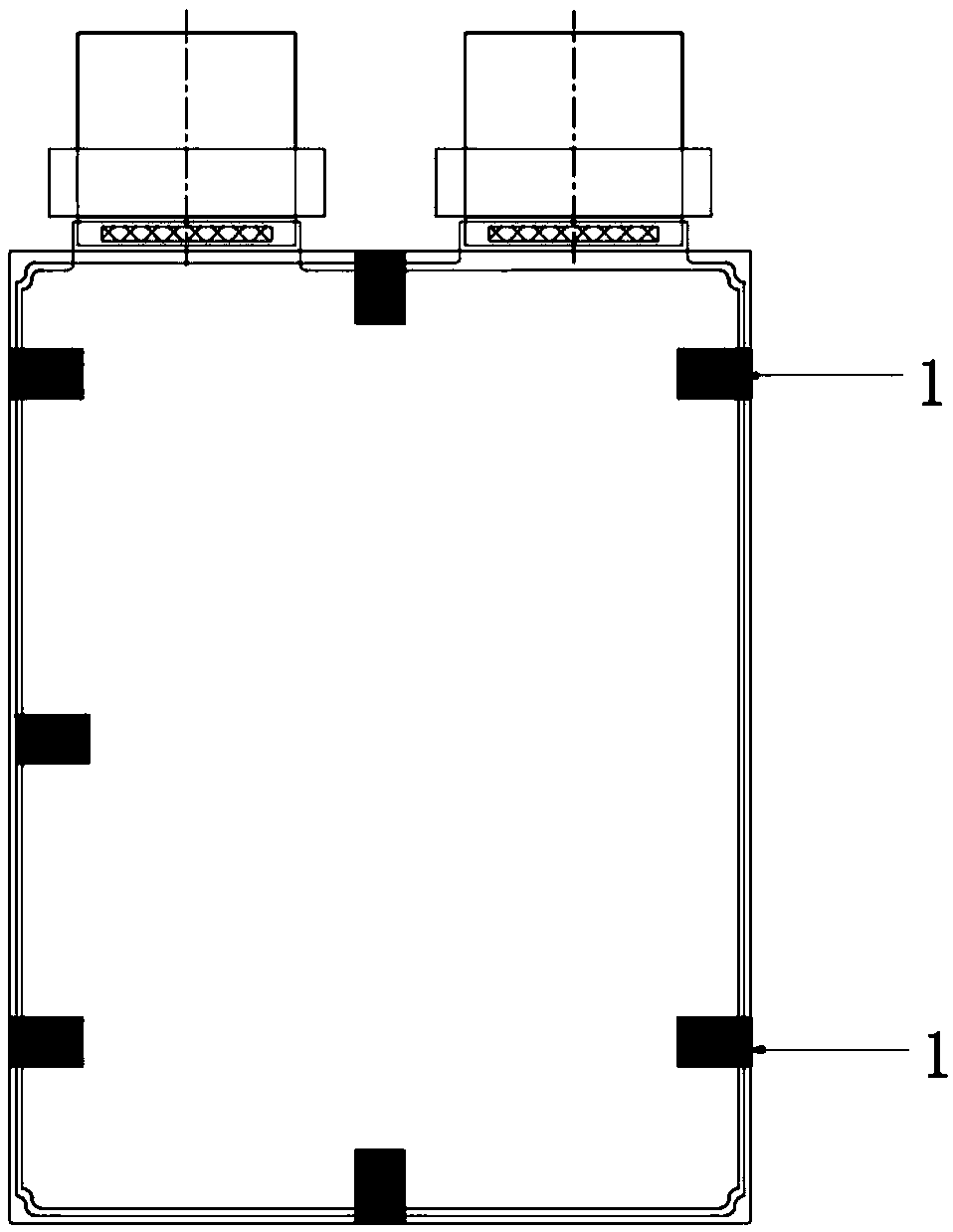

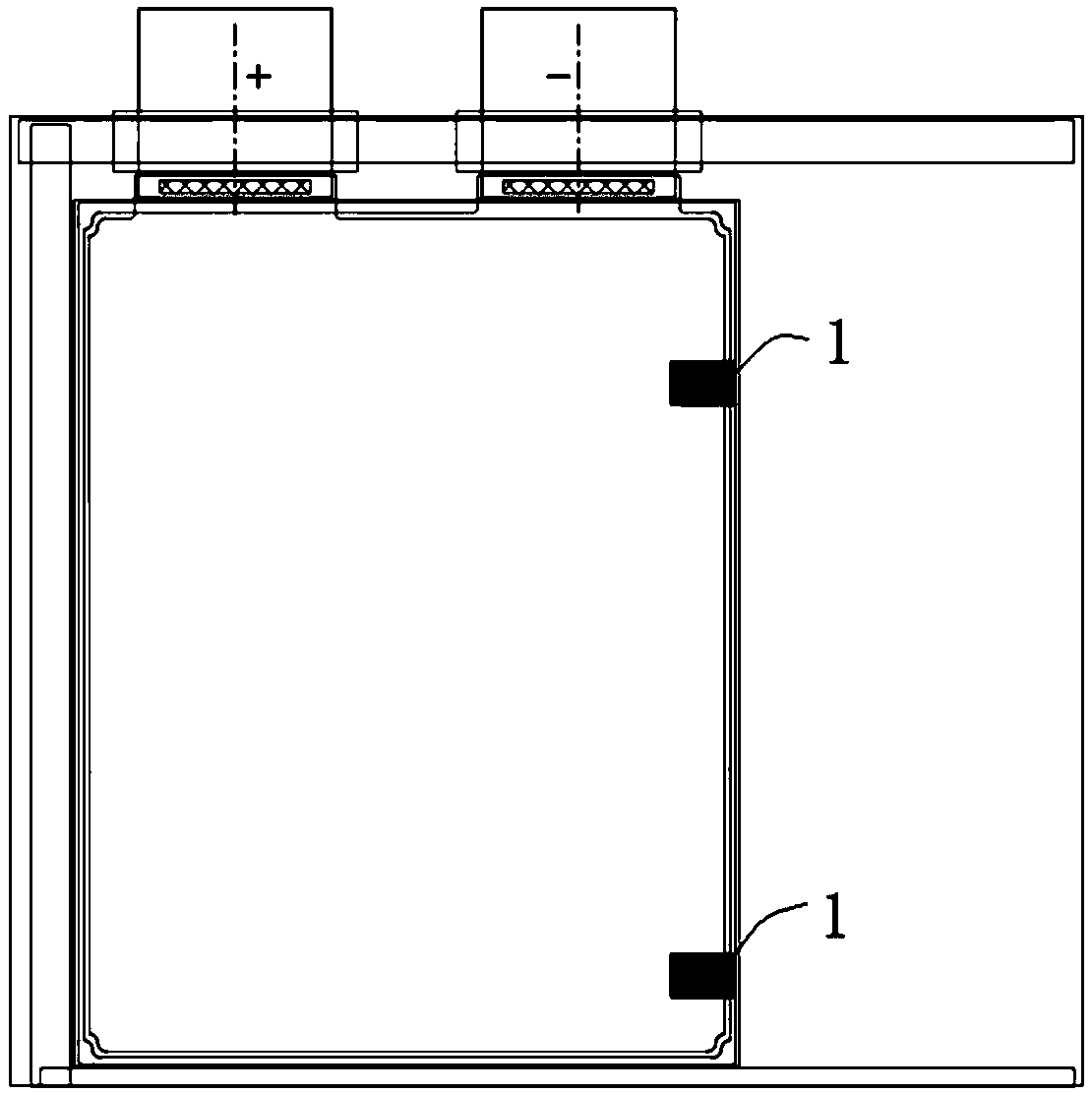

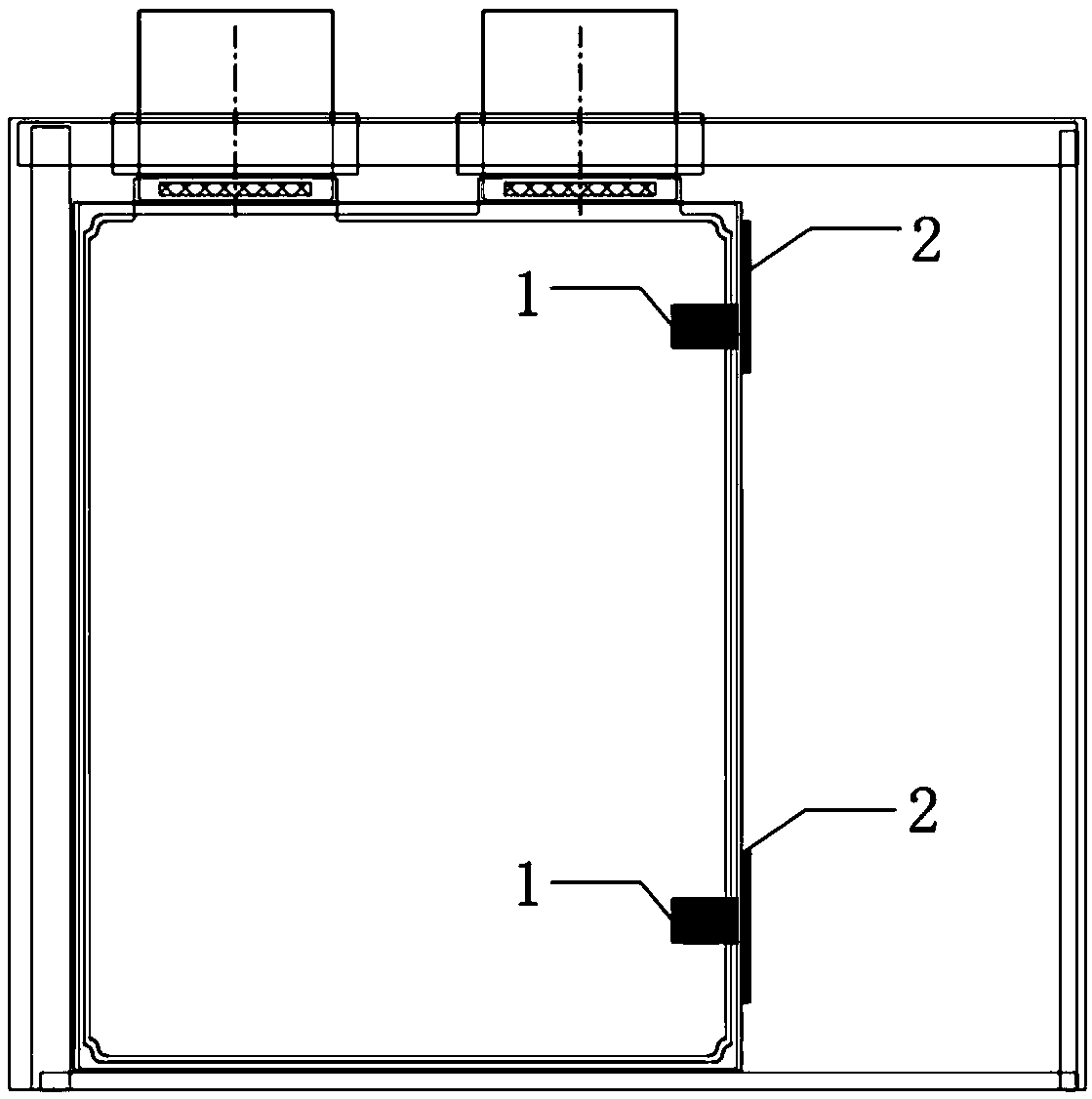

[0027] 2) Use adhesive tape to bond the thickness of both sides of the cell to fix the layers in the cell, such as figure 1 As shown; when fixed, the starting end of the adhesive tape is bonded to the end surface of one side of the battery (the end surface is not a thickness surface, corresponding to the main surface formed by the length and width of the battery), and the free end is wound along the direction perpendicular to the extension of the tab. After passing through the thickness surface of the cell, it terminates on the end face on the other side of the cell. Use adhesive tape to fix the upper end of the cell close to the tab and the lower end of the cell away from the tab respectively. Use tapes to fix the thick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com